custom wire repeated bending test machine

Custom Wire Repeated Bending Test Machine Ensuring Quality and Durability

In the ever-evolving landscape of manufacturing and quality control, ensuring the durability and reliability of wire products is paramount. One critical tool that has emerged to address this need is the custom wire repeated bending test machine. This specialized equipment plays a vital role in evaluating the performance of wire under repetitive stress, ultimately ensuring that products meet industry standards and consumer expectations.

Understanding the Importance of Wire Testing

Wires are integral to countless applications, ranging from electrical systems to construction and automotive components. Given the diverse environments in which these wires operate, it is essential to assess their ability to withstand repetitive bending without succumbing to fatigue or failure. The functionality of a wire is often defined not just by its tensile strength, but also by its flexibility and resistance to deformation under repeated use.

That’s where the custom wire repeated bending test machine comes into play. This machine simulates real-world conditions that wires encounter throughout their lifecycle, enabling manufacturers to identify potential weaknesses and make necessary adjustments before mass production.

How the Custom Wire Repeated Bending Test Machine Works

Typically, the machine consists of a framework that securely holds the wire specimen and a bending mechanism that repeatedly flexes the wire at predetermined angles and frequencies

. The process is highly controlled, allowing engineers to vary parameters such as the angle of bend, the speed of the cycles, and the number of repetitions to closely mimic specific real-world conditions.During the test, various sensors and data acquisition systems monitor the wire's performance, capturing information related to deformation, cracks, or any other form of distress. These data points are crucial for understanding how the material behaves under stress and for validating design assumptions made during the product development phase.

custom wire repeated bending test machine

Customization for Diverse Applications

One of the standout features of these test machines is their customizability. Different industries have unique requirements based on the specific types of wires used and the conditions they face. For example, the demands on automotive wiring are vastly different from those on wires used in consumer electronics. Therefore, manufacturers often opt for custom configurations that align with their specific testing criteria.

This customization can include adjustments in the machine's bending mechanism, the ability to simulate environmental factors such as temperature and humidity, and the integration of advanced monitoring technology to provide real-time feedback during testing. Such versatility ensures that manufacturers can thoroughly evaluate the performance of their wire products under conditions that closely resemble actual usage.

Benefits of Using a Repeated Bending Test Machine

The primary advantage of employing a custom wire repeated bending test machine is enhanced product quality. By identifying potential failure points during the design and testing phases, manufacturers can mitigate risks, reduce warranty claims, and enhance customer satisfaction. Additionally, thorough testing allows for compliance with industry regulations and standards, which can be crucial for market access.

Moreover, the insights gained from these tests can significantly impact the design process. Engineers may find opportunities to modify the material composition, alter geometric designs, or adjust manufacturing processes to improve overall durability. This proactive approach to testing cultivates a culture of continuous improvement within organizations.

Conclusion

In a world where reliability and durability are non-negotiable, the custom wire repeated bending test machine stands as a beacon of innovation in the manufacturing process. By allowing manufacturers to replicate and assess the stresses that wires will endure in real life, these machines not only enhance product quality but also drive industry standards forward. As technology advances, we can only expect these machines to become even more sophisticated, further improving our ability to ensure that wire products are built to last even in the most demanding environments. The need for rigorous testing is undeniable, and the custom wire repeated bending test machine is a vital tool in achieving excellence in wire product manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

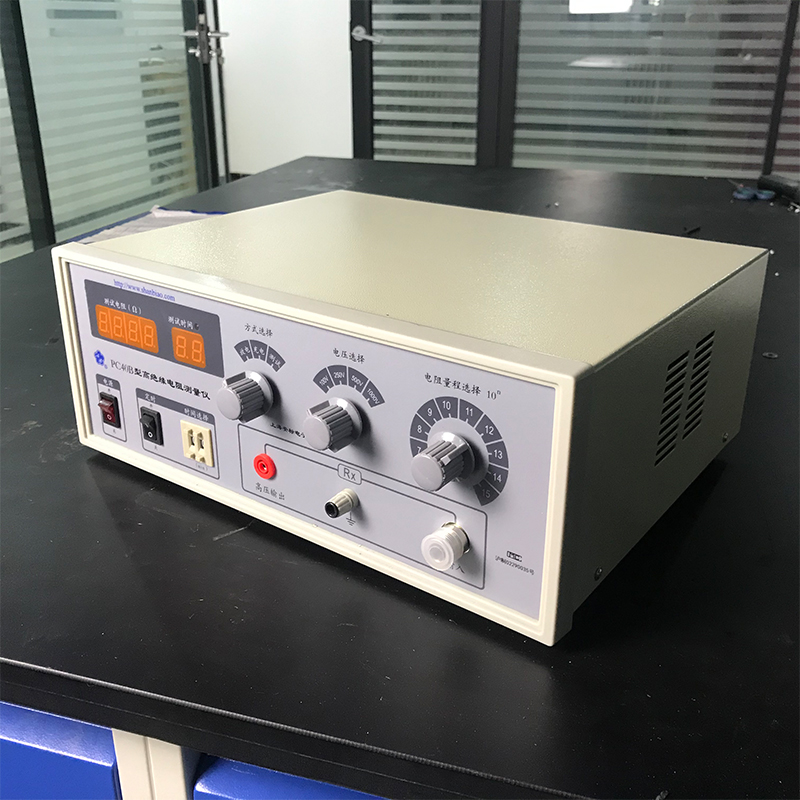

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy