dc insulation resistance tester exporters

Understanding DC Insulation Resistance Testers and the Role of Exporters

In the ever-evolving world of electrical engineering and maintenance, ensuring the safety and reliability of electrical systems is of paramount importance. One of the critical tools used in this regard is the DC insulation resistance tester. This device plays a vital role in assessing the integrity of electrical insulations, contributing to the overall safety and efficiency of electrical installations.

What is a DC Insulation Resistance Tester?

A DC insulation resistance tester is an instrument designed to measure the resistance of electrical insulation materials, typically in high voltage applications. It applies a direct current (DC) voltage to the insulation being tested, allowing the technician to determine the resistance level. High resistance values indicate good insulation, while low resistance values signal potential issues that could lead to electrical failures or hazards.

These testers are essential for various applications, including

1. Routine Maintenance Regular testing helps detect insulation degradation over time, allowing for proactive maintenance and avoidance of costly downtimes. 2. New Installations Before a new electrical system goes live, ensuring that its insulation is intact is critical for safety and compliance. 3. Troubleshooting When electrical issues arise, insulation resistance testing can help pinpoint the problem, particularly in identifying short circuits and leakage currents.

Key Features of DC Insulation Resistance Testers

Modern DC insulation resistance testers come equipped with various features that enhance their usability and accuracy

- Multiple Test Voltages Many testers offer selectable output voltages (e.g., 250V, 500V, 1000V), allowing users to test a wide range of electrical systems and insulation types. - Digital Displays These testers come with clear digital readouts that make it easy to interpret test results quickly. - Data Logging Advanced models can store test results, enabling users to track insulation performance over time and generate reports. - User-Friendly Interfaces Many devices feature intuitive controls and prompts, making them accessible for users with varying levels of expertise.

dc insulation resistance tester exporters

The Importance of Exporters in the Market

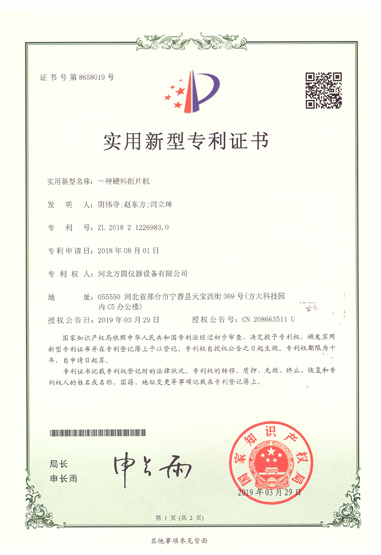

As demand for DC insulation resistance testers grows across various industries, exporters play a crucial role in bringing these essential tools to market. They facilitate the distribution of quality testing equipment, ensuring that electrical engineers and technicians around the world have access to the latest technology and innovations.

1. Quality Assurance Established exporters often collaborate with reputable manufacturers, guaranteeing that the products meet international standards. They ensure that only reliable and compliant devices reach the end users. 2. Market Expansion Exporters help manufacturers reach new markets, broadening their customer base and enhancing global trade. This is particularly vital in regions with increasing industrial activities requiring robust electrical infrastructure. 3. Technical Support Many exporters provide after-sales support, including training and troubleshooting assistance, ensuring that users can operate the devices effectively and maximize their utility.

Future Trends in Testing and Exporting

The market for DC insulation resistance testers is expected to evolve, driven by technological advancements and growing awareness of electrical safety. Innovations such as smart testers equipped with IoT capabilities may emerge, allowing real-time monitoring and data analysis.

Moreover, as industries worldwide prioritize safety and compliance, the demand for reliable testing equipment will likely increase. Exporters must adapt to this changing landscape, focusing on sustainable practices and expanding their product offerings to cater to a broader array of applications.

Conclusion

DC insulation resistance testers are invaluable tools in maintaining electrical safety and efficiency. Their significance cannot be overstated, especially in a world increasingly reliant on sophisticated electrical systems. Exporters are essential in this ecosystem, bridging gaps between manufacturers and end users while promoting quality, innovation, and safety standards. As technology advances and the demand for such testing equipment grows, both manufacturers and exporters must stay ahead of trends to ensure that the electrical industry continues to thrive safely and efficiently.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy