Designing a Personalized Traditional Tensile Testing Machine for Enhanced Material Analysis

Customizing a Traditional Tensile Tester Enhancing Materials Testing for Modern Applications

In the realm of materials science and engineering, the importance of tensile testing cannot be overstated. Tensile testers, designed to determine the mechanical properties of materials by applying a uniaxial load until failure, are essential for understanding material behavior under stress. While traditional tensile testers have been the industry standard for decades, there is a growing need for customized solutions that meet the diverse demands of modern applications.

Understanding the Traditional Tensile Tester

A traditional tensile tester consists of a few key components a load frame, a loading mechanism, grips or fixtures to hold the specimen, and a testing machine that measures the applied force and elongation. The test follows a standardized process, where a specimen is subjected to tension until it fractures, allowing engineers to assess its yield strength, tensile strength, and elongation at break.

Despite their effectiveness, traditional tensile testers may not cater to specific requirements of different materials or unique testing scenarios

. This limitation has prompted the shift toward customized tensile testing solutions that can accommodate a wider variety of materials, shapes, and sizes.Customization A Necessity for Modern Testing

The need for customization arises from several factors. First, industries are increasingly dealing with advanced materials such as composites, polymers, and biopolymers, each exhibiting varying mechanical properties and behaviors. A one-size-fits-all tensile tester may not accurately reflect the performance of these contemporary materials, leading to potentially questionable results.

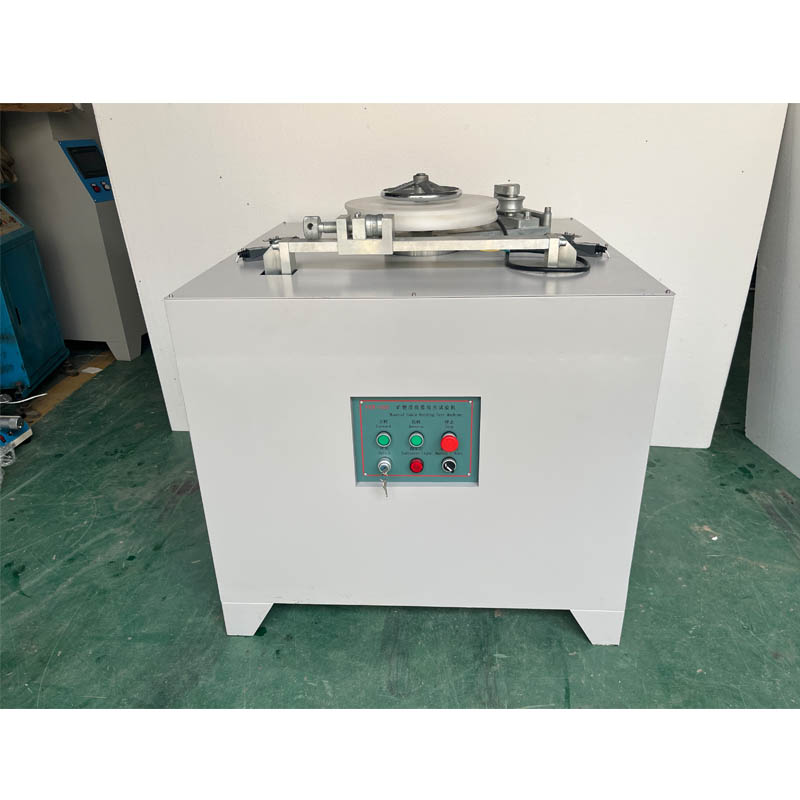

custom a traditional tensile tester

Additionally, as manufacturing processes evolve, the physical form of materials also changes. Custom fixtures or grips may be necessary to securely hold irregularly shaped specimens or materials that require unique testing conditions. For instance, testing thick-walled pipes or foams demands specialized grips to avoid slippage or damage during testing.

Another vital aspect is the integration of digital technology. Traditional tensile testers often rely on analog systems for data acquisition and analysis. However, customized tensile testers can incorporate advanced sensors, data loggers, and software solutions that provide real-time monitoring, detailed analysis, and seamless integration with other laboratory equipment. This technological integration not only enhances precision but also facilitates compliance with rigorous industry standards.

Designing a Custom Tensile Tester

When designing a custom tensile tester, engineers must consider various parameters tailored to specific applications. The selection of the load cell, testing speed, and the overall capacity should align with the intended materials and expected stress ranges. Adjustments can be made to the configuration of grips to accommodate different shapes and sizes while ensuring that the specimen is held securely without introducing additional stress concentrations.

The incorporation of user-friendly interfaces and advanced software can significantly improve the usability of a custom tensile tester. Automated data analysis features allow for quicker decision-making and help in recognizing trends over time, ultimately contributing to a more efficient testing process.

Conclusion

In conclusion, customizing a traditional tensile tester is no longer a luxury but a necessity for industries operating in an era of rapid material innovation and complexity. By tailoring tensile testing solutions to meet individual requirements, researchers and engineers can ensure precise and reliable data that truly reflects the performance of materials under stress. This ability to adapt and innovate will be crucial as we venture further into a future where advanced materials play a pivotal role in shaping technology and industry. As we continue to push the boundaries of material science, the role of customized tensile testing solutions will undoubtedly become increasingly significant.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy