Leading Provider of Advanced Digital Optical Profile Projectors for Precision Measurement Solutions

The Evolution of Digital Optical Profile Projectors A Modern Solution for Precision Measurement

In the realm of manufacturing and engineering, precision is paramount. Among the tools that have evolved to meet this demand, digital optical profile projectors have become indispensable. These advanced devices provide detailed analysis and measurement of intricate parts, enhancing quality control processes and ensuring that products meet exact specifications.

Digital optical profile projectors combine optical technology with digital advancements to deliver accurate and reliable results. Traditionally, profile projectors employed high-intensity light to project a silhouette of an object's profile onto a screen. Operators would measure dimensions manually, often relying on rudimentary calibration techniques. However, the advent of digital technology has transformed this process, making it more efficient and user-friendly.

Today’s digital optical profile projectors are equipped with sophisticated imaging technology that captures high-resolution images of the projected profiles. These images can be analyzed with precision software that enables operators to take measurements quickly and accurately. This is particularly crucial in industries where even the slightest deviation from specifications can lead to product failure or safety issues.

Among the key benefits of digital optical profile projectors is their ability to store and recall measurement data. This capability not only saves time but also provides a record of measurements that can be reviewed and compared over time. Quality managers can easily track trends and identify potential issues in the manufacturing process, allowing for timely interventions that can save costs and improve product quality.

digital optical profile projectors company

Additionally, modern digital optical profile projectors often come with advanced features such as automatic edge detection, which simplifies the measurement of complex shapes. Traditional methods often required skilled operators to painstakingly identify edges for measurement. In contrast, digital projectors can automatically detect edges and provide measurements based on preset parameters, minimizing human error and increasing throughput.

Furthermore, many manufacturers of digital optical profile projectors have embraced Industry 4.0 concepts, allowing their devices to connect to broader manufacturing ecosystems. This connectivity enables real-time monitoring and data collection, facilitating better decision-making based on accurate and timely information. Companies can integrate these profile projectors into their existing quality management systems, aligning them with other digital tools in their manufacturing processes.

The market for digital optical profile projectors is continuously growing, with various companies competing to innovate and enhance their offerings. As industries push for greater automation and precision, these devices are set to play a crucial role in the future of manufacturing. Their ability to provide rapid, accurate analysis of parts will become increasingly vital as product designs grow more complex and quality standards tighten.

In conclusion, digital optical profile projectors represent a significant advancement in the pursuit of precision in manufacturing. By combining traditional optical measurement techniques with cutting-edge digital technology, these devices offer unparalleled accuracy and efficiency. As the landscape of manufacturing continues to evolve, companies that invest in digital optical profile projectors are well-positioned to enhance their quality control processes and maintain a competitive edge in an ever-demanding market.

-

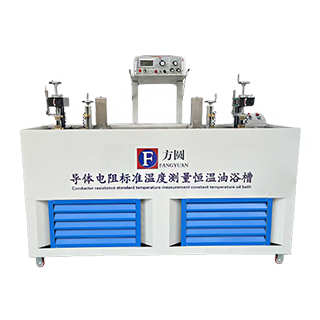

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy