Exporting High-Precision Digital Optical Profile Projectors for Quality Measurement Solutions

Understanding Digital Optical Profile Projectors and Their Export Markets

Digital optical profile projectors have emerged as vital tools in various manufacturing sectors, particularly in precision engineering and quality control. These devices are essential for inspecting and measuring complex profiles of machined parts, ensuring that they meet the stringent specifications set by industry standards. As global manufacturing continues to evolve, the demand for these advanced measuring instruments has led to significant opportunities for exporters in this niche market.

The Role of Digital Optical Profile Projectors

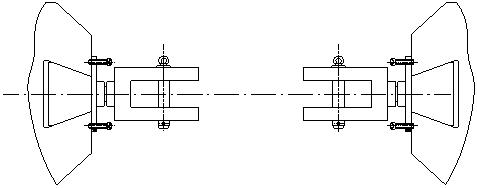

A digital optical profile projector utilizes optical magnification and projection technology to display the silhouette of a part on a screen. This allows engineers and quality control inspectors to analyze the part's geometry in detail. Unlike traditional profile projectors, which rely on analog systems, digital versions offer enhanced accuracy, data storage capabilities, and integration with computer-aided design (CAD) systems. This has made them increasingly popular in fields such as aerospace, automotive, and medical device manufacturing, where precision is paramount.

The functionality of these projectors makes them indispensable in the inspection process. They not only enable real-time measurements but also store data for future comparison and analysis, thereby enhancing the quality assurance process. Moreover, with the shift towards automation and smart manufacturing, the integration of digital optical profile projectors with other technological solutions, such as machine vision systems, is becoming more commonplace.

Exporting Digital Optical Profile Projectors

As the demand for digital optical profile projectors grows, so does the opportunity for exporters. Manufacturers are increasingly looking towards international markets to expand their customer base, driven by the need for advanced measurement solutions across the globe. Exporting these sophisticated devices requires understanding the unique needs of different markets, as well as compliance with international quality standards.

digital optical profile projectors exporter

Successful exporters typically focus on regions with burgeoning manufacturing sectors, such as Southeast Asia, Eastern Europe, and parts of Africa. The growing investment in industrial development in these areas presents a ripe opportunity for suppliers of precision measurement instruments. Furthermore, established markets like North America and Western Europe still present significant opportunities due to the continuous need for high-precision instruments in industries like automotive, electronics, and defense.

Challenges in the Export Market

Despite the promising landscape for exporters of digital optical profile projectors, several challenges must be navigated. One of the primary obstacles is the varying regulatory standards across different countries. Exporters must familiarize themselves with local regulations and certification requirements to ensure compliance. Failure to meet these standards can lead to delays, additional costs, and potential loss of market access.

Additionally, exporters face competition from both domestic manufacturers and other international players. To differentiate themselves, exporters must emphasize the quality, reliability, and technological advancements of their products. Establishing strong relationships with local distributors can also facilitate better market penetration and customer service.

Future Outlook

The future of digital optical profile projectors in export markets looks bright. With ongoing advancements in technology, manufacturers are likely to seek even more precise and user-friendly measurement solutions. As industries continue to embrace automation and smart manufacturing practices, the role of digital optical profile projectors will only become more crucial.

In conclusion, digital optical profile projectors represent a significant opportunity for exporters looking to capitalize on the global demand for precision measurement solutions. With a thorough understanding of market dynamics, regulatory compliance, and a focus on quality and innovation, exporters can effectively navigate the complex landscape of international trade and contribute to the evolution of manufacturing technology. By harnessing these powerful tools, manufacturers can ensure that their production standards remain at the forefront of the industry.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy