digital optical profile projectors factories

Digital Optical Profile Projectors Transforming Precision Measurement in Factories

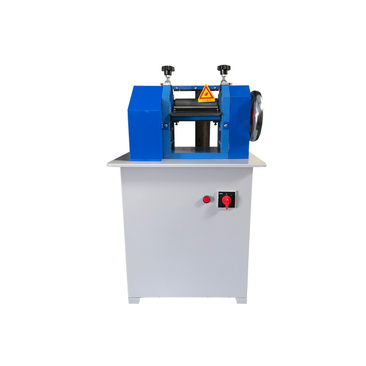

In the realm of manufacturing and quality control, the importance of precision measurement cannot be overstated. As industries continue to evolve with technological advancements, digital optical profile projectors have emerged as essential tools in factories around the world. These sophisticated instruments enable engineers and quality assurance professionals to achieve remarkable accuracy in measuring complex shapes and profiles, thereby enhancing overall production efficiency and product quality.

Digital optical profile projectors operate on a simple yet effective principle. They utilize light to project the contours of an object onto a screen, allowing for real-time analysis and measurement. Unlike traditional projectors, the digital variant integrates advanced imaging technology, which captures high-resolution images for precise evaluation. This integration of optical and digital technologies provides manufacturers with the capability to measure both two-dimensional and three-dimensional components with unparalleled accuracy.

One of the most significant benefits of digital optical profile projectors is their ability to handle a wide range of materials and components. From metal parts to plastic molds, these projectors can be utilized in various manufacturing sectors, including automotive, aerospace, electronics, and medical devices. The flexibility offered by these devices enables manufacturers to streamline their quality control processes, ensuring that all products meet the stringent standards required in their respective industries.

digital optical profile projectors factories

Furthermore, digital optical profile projectors enhance productivity by reducing the time required for measurements. Traditional measurement methods, such as calipers and micrometers, can be time-consuming and often lead to human error. In contrast, digital optical projectors provide instantaneous readings and allow for quick comparisons against CAD models or specifications. This rapid evaluation process not only saves time but also minimizes the risk of errors, which can lead to costly rework and delays in production.

In addition to speed and accuracy, the advanced software that accompanies digital optical projectors plays a crucial role in factory settings. These software programs often come equipped with features that allow for detailed analysis, programming, and data storage. Manufacturers can easily archive measurement data, conduct statistical process control, and generate reports for traceability. Such capabilities not only enhance quality assurance protocols but also comply with regulatory requirements, ensuring that manufacturers stay ahead in an increasingly competitive marketplace.

Moreover, the use of digital optical profile projectors promotes a culture of continuous improvement within factories. By facilitating regular inspections and measurements, manufacturers can identify trends and variations in their processes. This proactive approach enables teams to address potential issues before they escalate, ultimately leading to higher yield rates and improved customer satisfaction. The integration of these projectors into daily operations encourages a meticulous focus on quality, which in turn elevates the overall performance of the factory.

In conclusion, digital optical profile projectors represent a significant advancement in the field of precision measurement within manufacturing environments. Their ability to provide accurate, efficient, and comprehensive measurement solutions makes them invaluable assets in modern factories. As industries strive for heightened quality standards and operational efficiency, the adoption of such cutting-edge technologies will undoubtedly play a pivotal role in shaping the future of manufacturing. By investing in digital optical profile projectors, factories can not only improve their quality control processes but also enhance productivity and maintain a competitive edge in the market. As the landscape of manufacturing continues to change, embracing these innovations is not just beneficial; it is essential for sustained success.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy