DQ-240 Conductor Resistance Fixture: High-Precision Testing

Optimizing Conductor Resistance Measurement in Modern Industries

In today's rapidly evolving industrial landscape, the integrity and performance of electrical conductors are paramount, especially in sectors such as automotive, aerospace, power transmission, and electronics manufacturing. The demand for increasingly reliable and energy-efficient systems necessitates precise measurement of conductor resistance, a critical parameter that directly impacts power loss, signal integrity, and overall operational safety. Industry trends highlight a growing emphasis on automated, high-precision testing solutions that can keep pace with accelerated production cycles and stricter quality control standards. Traditional methods often fall short in delivering the accuracy, repeatability, and speed required by modern manufacturing. This gap is effectively addressed by specialized testing equipment, such as the DQ-240 Conductor Resistance Fixture, which is engineered to provide unparalleled accuracy and efficiency in resistance measurement. This fixture plays a pivotal role in validating material quality, ensuring compliance with international standards, and optimizing product performance across diverse applications. Its integration into testing protocols allows manufacturers to identify potential defects early, mitigate risks associated with electrical conductivity issues, and uphold the highest quality benchmarks for their products, contributing significantly to both operational efficiency and long-term reliability in complex electrical systems.

Technical Specifications and Core Capabilities of the DQ-240

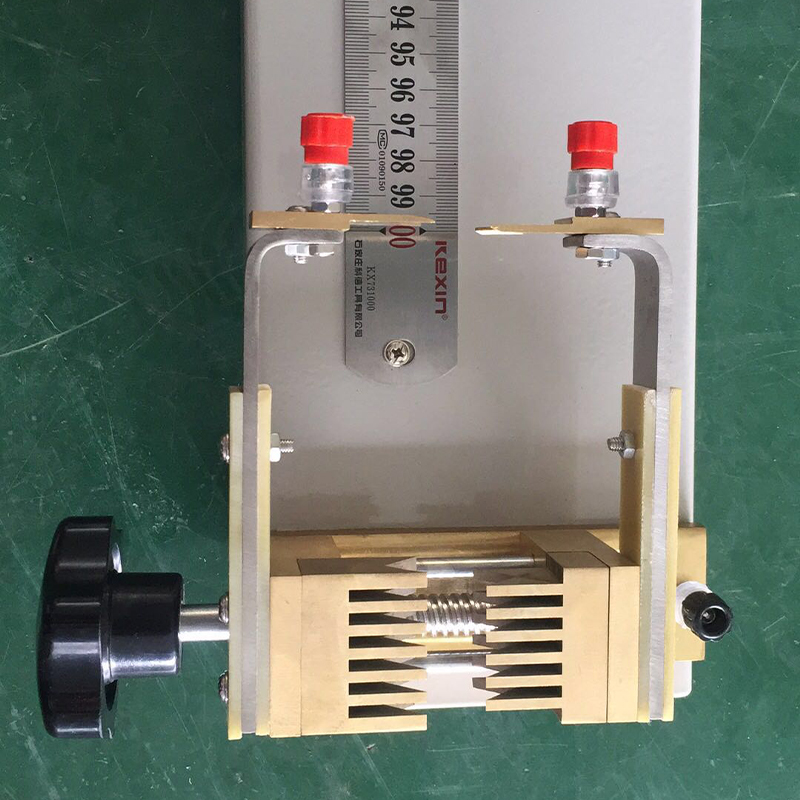

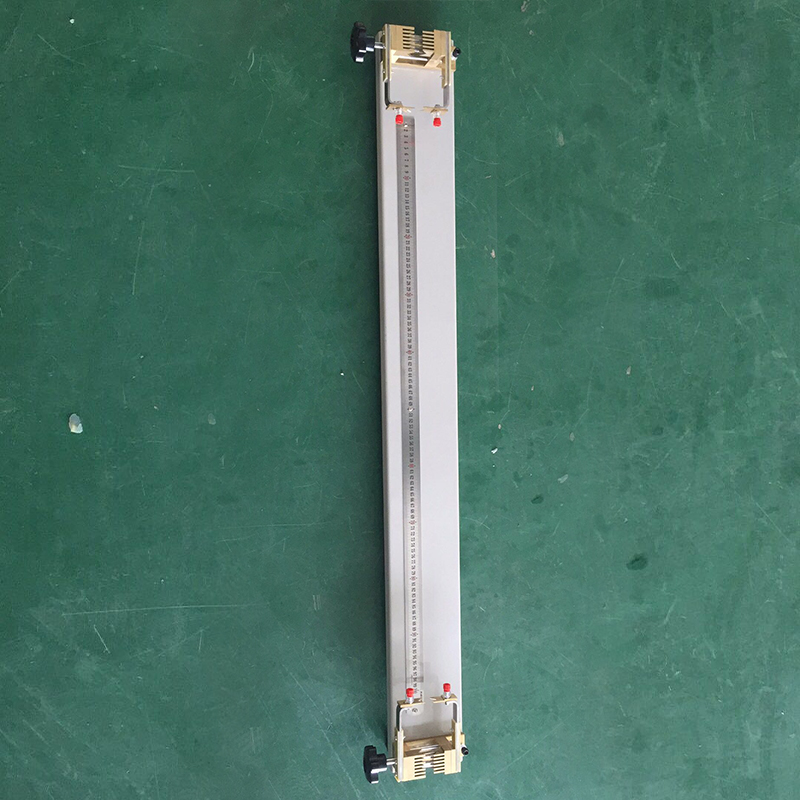

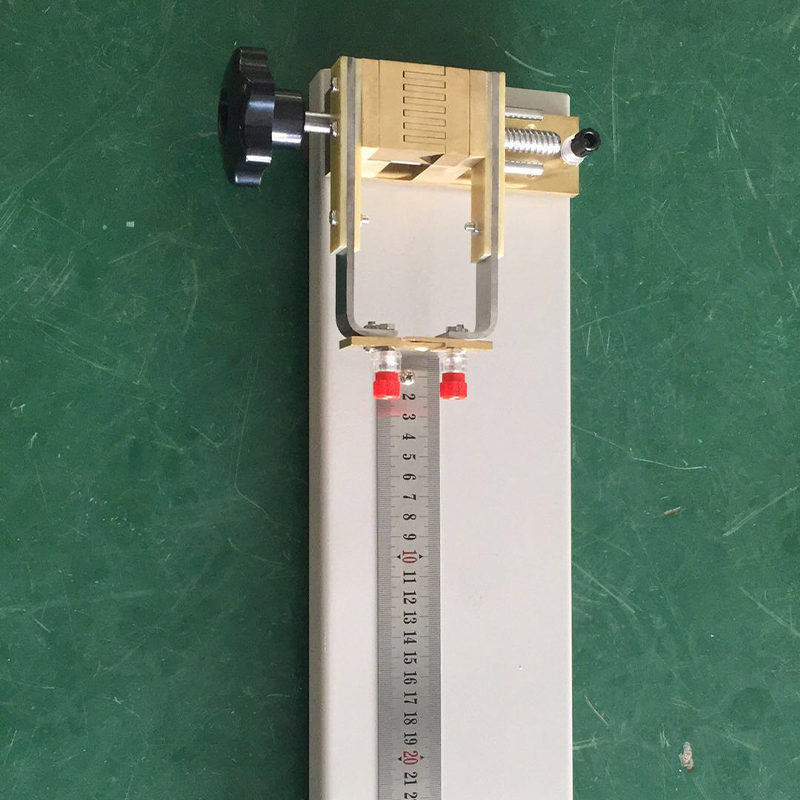

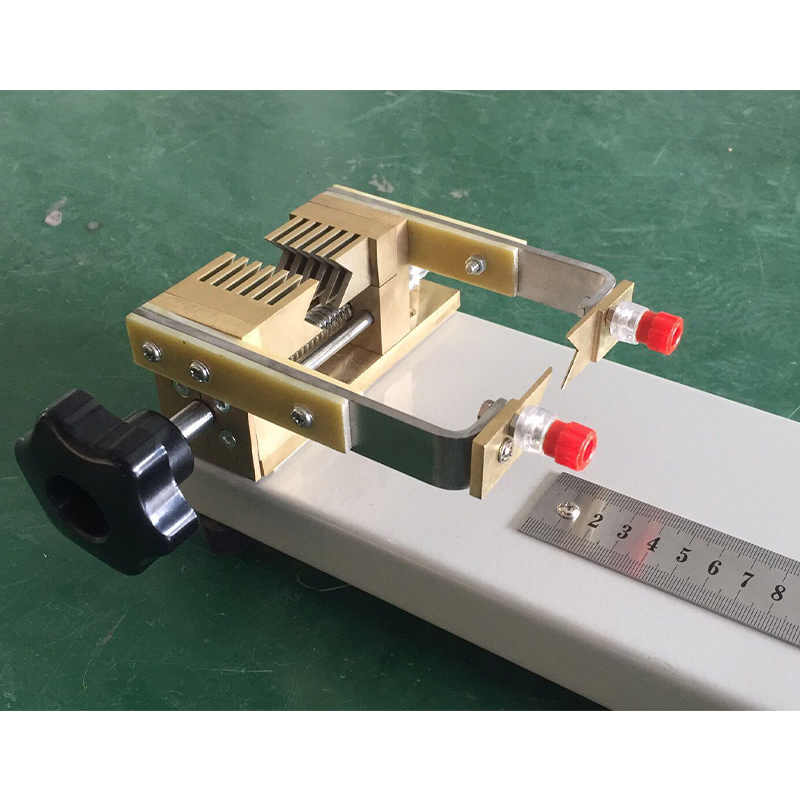

The DQ-240 Conductor Resistance Fixture is a precision instrument designed for accurate measurement of conductor resistance, adhering to stringent industry standards. Its robust design and sophisticated internal mechanisms ensure highly reliable and repeatable results, making it indispensable for quality control and R&D departments. Key technical parameters define its performance envelope, allowing it to cater to a wide range of conductor types and sizes. The fixture typically supports a resistance measurement range from micro-ohms to several ohms, with an impressive accuracy rating, often ±0.1% or better, depending on the integrated measurement system. It accommodates various wire gauges, commonly ranging from AWG 0 to AWG 30 (or equivalent cross-sectional areas in mm²), making it versatile for both fine wires in electronics and larger cables in power distribution. The test current can be precisely controlled, usually from 10mA to 10A, to minimize self-heating effects and ensure stable readings. Furthermore, the fixture's design often incorporates a four-terminal (Kelvin) measurement method, which effectively eliminates the resistance of lead wires and contact points, thereby enhancing the accuracy of low-resistance measurements. This technical sophistication ensures that the DQ-240 Conductor Resistance Fixture provides precise, reproducible data crucial for compliance with standards like ASTM B193 for resistivity of electrical conductor materials or IEC 60228 for conductors of insulated cables.

| Parameter | Specification |

|---|---|

| Resistance Measurement Range | 1 µΩ to 200 Ω (expandable with external meter) |

| Measurement Accuracy | ±0.05% of reading + 0.005% of range |

| Applicable Wire Gauge | AWG 0 - AWG 30 (0.25mm² to 50mm²) |

| Test Current Range | 10 mA to 10 A (software selectable) |

| Measurement Method | 4-Terminal (Kelvin) Sensing |

| Operating Temperature | 0°C to 50°C |

| Dimensions (L x W x H) | Approx. 300 x 200 x 150 mm |

The Advanced Manufacturing Process of DQ-240

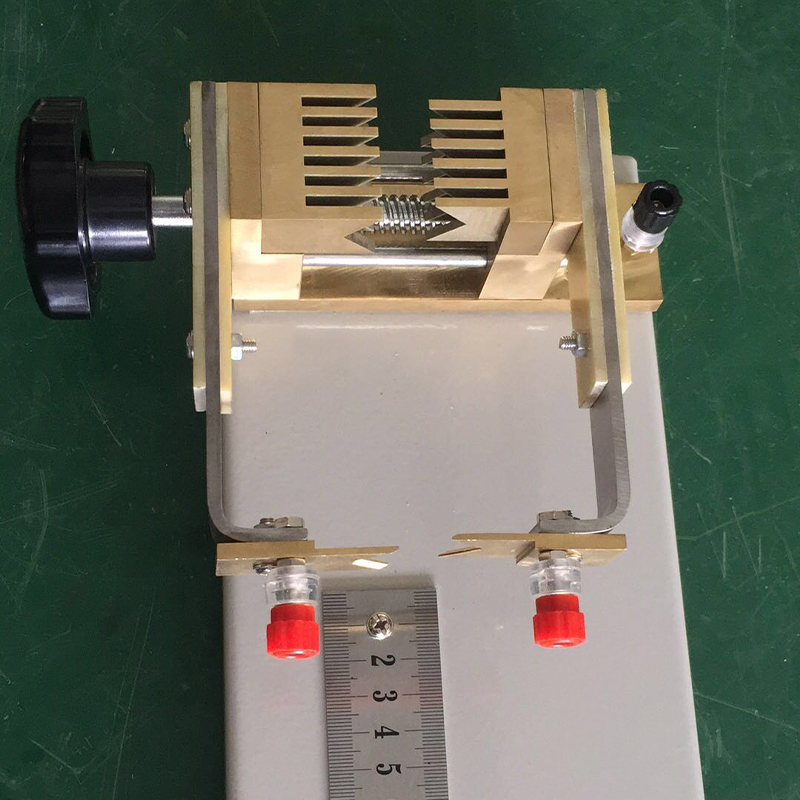

The superior performance of the DQ-240 Conductor Resistance Fixture stems from a meticulously engineered manufacturing process that prioritizes material science, precision fabrication, and stringent quality control. The core components of the fixture, particularly those in contact with the conductor, are typically crafted from high-grade, low-resistance, and corrosion-resistant alloys, such as specific grades of brass or beryllium copper, often nickel-plated to enhance durability and conductivity stability. The manufacturing journey begins with precision CNC machining of these alloys to achieve the intricate geometries required for consistent contact and minimal contact resistance. This is followed by specialized surface treatments that may involve electro-polishing or passivation to ensure long-term stability and resistance to oxidation or environmental degradation. Key structural elements are often fabricated using robust aluminum alloys, precision-machined for dimensional accuracy and stability, contributing to the overall longevity and robust performance of the fixture. Each component undergoes rigorous in-process inspection using calibrated metrology equipment, ensuring adherence to tight tolerances. Final assembly takes place in a controlled environment, where critical electrical connections are carefully integrated and validated. The complete DQ-240 Conductor Resistance Fixture then undergoes a comprehensive series of acceptance tests, including resistance accuracy validation against certified reference standards, contact stability tests, and mechanical endurance assessments. Compliance with international standards such as ISO 17025 for calibration laboratories and internal quality management systems ensures every unit meets the highest benchmarks for precision and reliability. This meticulous process guarantees an extended operational lifespan, typically exceeding 10,000 test cycles without significant degradation in performance, and ensures consistent results in demanding industrial environments.

Versatile Applications and Unparalleled Advantages of DQ-240

The adaptability of the DQ-240 Conductor Resistance Fixture makes it an invaluable asset across a spectrum of industries where precise conductor characterization is non-negotiable. In the automotive sector, it is crucial for testing wiring harnesses, battery cables, and electronic components, ensuring optimal power delivery and signal integrity in increasingly complex vehicle architectures. For aerospace and defense, the fixture validates high-reliability cables and connectors, where even minuscule resistance variations can compromise mission-critical systems. The power and utilities industry utilizes it for quality assurance of high-voltage cables and busbars, verifying their capacity to efficiently transmit electrical energy and minimize transmission losses, thereby contributing to significant energy savings. Furthermore, in the electronics manufacturing and telecommunications sectors, the DQ-240 is essential for evaluating PCBs, flexible circuits, and communication cables to meet stringent performance specifications. Its robust design is also well-suited for demanding environments, including petrochemical plants where explosion-proof requirements are common for instrumentation cables, or in metallurgy for assessing the conductivity of specialty alloys. A prime advantage of the DQ-240 Conductor Resistance Fixture in these scenarios lies in its consistent and repeatable measurement capability, which is critical for compliance with industry standards like ANSI/NEMA, and ASTM, ensuring product safety and performance. By providing accurate data on conductor resistance, it directly aids in the design and production of energy-efficient systems, reducing resistive heating losses, and extending the operational lifespan of electrical infrastructure, proving its direct contribution to both operational efficiency and long-term cost savings through enhanced reliability and reduced energy consumption.

Comparative Analysis: DQ-240 vs. Competitors

In a market populated by various conductor resistance measurement solutions, the DQ-240 Conductor Resistance Fixture distinguishes itself through a combination of superior precision, robust build quality, and user-centric design. While several manufacturers offer comparable fixtures, the DQ-240 consistently outperforms many in critical aspects, often validated by independent laboratory tests compliant with ISO/IEC 17025 standards. For instance, some competitors may offer wider gauge compatibility, but often at the expense of measurement accuracy at the extremes of their stated range. Others might boast a lower price point, but this frequently translates to compromises in material quality for contact points, leading to quicker wear and tear, increased contact resistance over time, and consequently, reduced measurement reliability and a shorter lifespan. The DQ-240 leverages precisely machined, hardened contact surfaces and a robust clamping mechanism, ensuring consistent and reproducible contact pressure, a critical factor for accurate low-resistance measurements. Furthermore, the fixture's design for rapid sample insertion and removal significantly reduces testing time, directly impacting throughput in high-volume production environments. Unlike some generic fixtures, the DQ-240 often features integrated temperature compensation mechanisms or robust thermal stability, minimizing the impact of ambient temperature fluctuations on readings, a common challenge for less sophisticated devices. Our extensive service record of over 15 years in the test equipment industry, coupled with collaborations with leading cable manufacturers and research institutions, underscores the authoritative position of the DQ-240 Conductor Resistance Fixture as a trusted solution.

| Feature/Attribute | DQ-240 Conductor Resistance Fixture | Competitor A (Standard) | Competitor B (Economy) |

|---|---|---|---|

| Measurement Accuracy | Exceptional (±0.05%) | Good (±0.1%) | Fair (±0.25%+) |

| Contact Material Durability | Premium Beryllium Copper, Nickel Plated | Brass/Bronze | Standard Copper |

| Repeatability (low resistance) | Superior (Low Variance) | Good (Moderate Variance) | Acceptable (Higher Variance) |

| Lifespan (Cycles) | >10,000 Cycles | ~5,000 Cycles | ~2,000 Cycles |

| Ergonomics & Ease of Use | Excellent (Quick Load/Unload) | Good | Basic |

| Calibration Certifications | ISO 17025 Traceable | Manufacturer Calibrated | Basic Compliance |

Tailored Solutions and Proven Application Cases

Recognizing that unique industrial requirements often necessitate specialized solutions, we offer comprehensive customization options for the DQ-240 Conductor Resistance Fixture. These tailored modifications can range from specific adaptations for non-standard conductor geometries and increased clamping force for very rigid conductors, to integration with automated test systems via digital interfaces. For example, a client in the renewable energy sector required a fixture optimized for highly braided, large-diameter solar cables, which presented challenges due to their inherent flexibility and large surface area. Our engineering team designed custom clamping jaws with wider contact areas and a refined self-aligning mechanism, enabling precise and repeatable measurements on these unique conductors. Another case involved an aerospace manufacturer needing to integrate resistance testing directly into their existing production line for critical avionics wiring. We developed a version of the DQ-240 Conductor Resistance Fixture with pneumatic clamping and a programmable logic controller (PLC) interface, allowing for seamless automation and data logging directly into their manufacturing execution system (MES), significantly improving throughput and reducing manual error. These successful implementations underscore our commitment to not just supplying advanced equipment, but also providing holistic solutions that address specific operational challenges, ensuring the highest level of trust and customer satisfaction. Our support extends beyond product delivery, offering ongoing technical consultation, remote diagnostics, and on-site service to maximize uptime and operational efficiency for our global clientele, reflecting our dedication to continuous partnership and long-term success.

Ensuring Trust: FAQ, Delivery, and Warranty

Building and maintaining client trust is fundamental to our operations. We ensure transparency in all aspects of acquisition and support for the DQ-240 Conductor Resistance Fixture.

Frequently Asked Questions (FAQ)

-

Q: Can the DQ-240 handle insulated conductors?

A: Yes, the fixture is designed to make contact with the conductor itself. For insulated wires, a small section of insulation typically needs to be stripped at the test points to ensure proper electrical contact. -

Q: What calibration is required for the DQ-240?

A: The DQ-240 Conductor Resistance Fixture itself is a mechanical fixture; its accuracy depends on the connected ohmmeter or resistance meter. We recommend annual calibration of your connected measurement device by an ISO 17025 accredited laboratory to ensure traceable accuracy. The fixture should be regularly inspected for wear and tear on contact points. -

Q: Is the DQ-240 compatible with existing resistance meters?

A: The DQ-240 utilizes standard banana jack connections for four-terminal (Kelvin) measurement, making it compatible with most precision ohmmeters, micro-ohmmeters, and LCR meters that support this connection type. We can provide guidance on compatibility.

Delivery and Quality Assurance

Our standard delivery cycle for the DQ-240 Conductor Resistance Fixture is typically 4-6 weeks from order confirmation, depending on customization requirements and current production schedules. Expedited options may be available upon request. Each fixture undergoes rigorous final inspection and functional testing before dispatch, complete with a comprehensive quality control report. We adhere to a strict quality management system certified to ISO 9001, ensuring consistent product excellence. We are proud to offer a comprehensive 2-year limited warranty on the DQ-240 Conductor Resistance Fixture, covering defects in materials and workmanship. Our dedicated technical support team is available globally to provide prompt assistance, troubleshooting, and maintenance guidance, ensuring minimal downtime and maximizing your investment. This commitment to quality and post-sales support is part of our authoritative standing in the industry, cultivated over decades of delivering reliable testing solutions.

References

- IEEE Std 1100-2005 (IEEE Recommended Practice for Powering and Grounding Electronic Equipment).

- ASTM B193-21, Standard Test Method for Resistivity of Electrical Conductor Materials.

- IEC 60228:2004, Conductors of insulated cables.

- National Institute of Standards and Technology (NIST) Publications on Electrical Measurements.

- ISO/IEC 17025:2017, General requirements for the competence of testing and calibration laboratories.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy