DQ-630/1200/2500 Conductor Resistance Clamp | Reliable Test

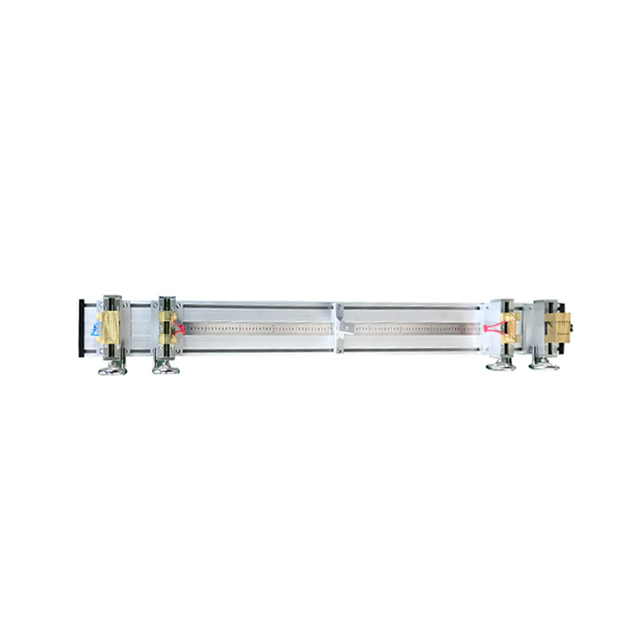

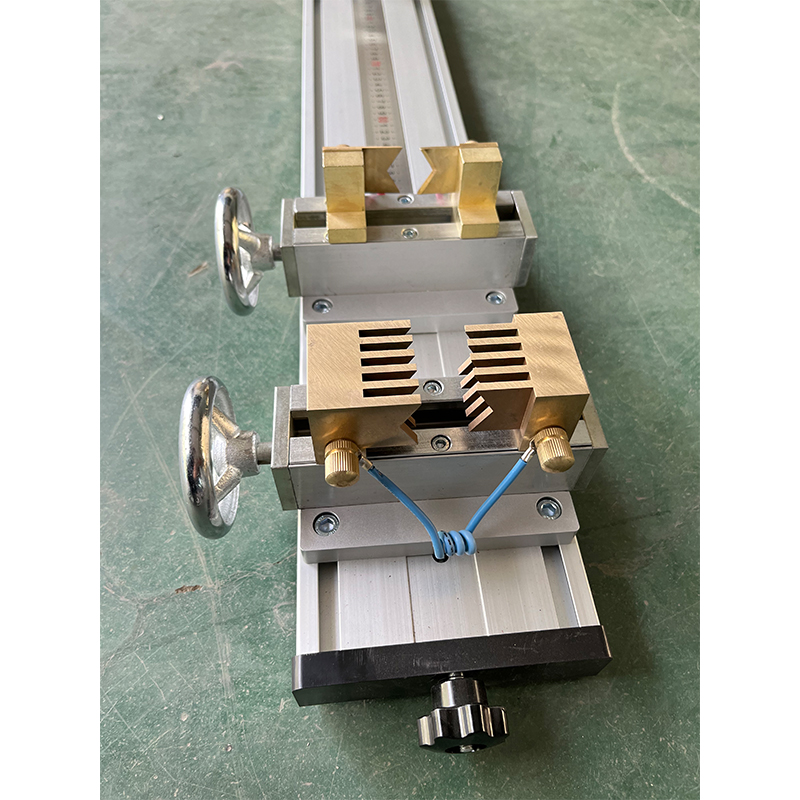

Advancing Electrical Infrastructure with DQ-630/1200/2500 Conductor Resistance Clamps

In the realm of high-current electrical transmission and distribution, the integrity of every connection point is paramount. Conductor resistance clamps, particularly the advanced DQ-630/1200/2500 Conductor Resistance Clamp series, play a critical role in ensuring optimal conductivity, minimizing power loss, and preventing overheating at critical junctions. These specialized clamps are engineered to provide a robust, low-resistance connection for high-amperage conductors, which are ubiquitous across heavy industries. The series, encompassing the DQ-630, DQ-1200, and DQ-2500 models, is designed to accommodate various current ratings—630A, 1200A, and 2500A respectively—making them versatile solutions for a wide spectrum of applications, from substation busbars to industrial power systems. The industry's increasing demand for energy efficiency and operational safety has driven significant advancements in clamp technology, focusing on materials with superior electrical and mechanical properties, enhanced manufacturing precision, and rigorous quality control. Trends indicate a clear shift towards clamps that offer not only high current capacity but also exceptional long-term stability, resistance to environmental degradation, and ease of installation, all while adhering to stringent international standards. This detailed overview will delve into the technical prowess, manufacturing excellence, diverse applications, and profound advantages offered by these state-of-the-art conductor resistance clamps, establishing their indispensable value in modern electrical infrastructure.

The core challenge in high-current connections lies in managing contact resistance – the opposition to current flow at the interface of two conductors. Even a seemingly small amount of resistance can lead to significant power dissipation as heat (I²R losses), which can degrade insulation, cause material fatigue, and ultimately lead to system failure. The DQ-630/1200/2500 Conductor Resistance Clamp directly addresses this by providing a large, consistent contact area with high clamping force, ensuring minimal resistance. Understanding the 'skin effect' in AC circuits, where current tends to flow on the surface of a conductor, further emphasizes the need for uniform contact across the entire surface to mitigate localized hotspots. These clamps are not merely connectors; they are precision-engineered components designed to manage thermal loads and mechanical stresses effectively, ensuring reliable performance over decades of service. Their robust design takes into account factors like thermal expansion coefficients of different metals, preventing loosening or excessive stress under varying operational temperatures. This proactive engineering approach minimizes the need for frequent maintenance and costly downtime, contributing significantly to the overall efficiency and reliability of electrical systems. The integration of advanced materials and sophisticated manufacturing techniques positions the DQ series at the forefront of conductor clamping technology, meeting the evolving needs of demanding industrial environments where performance cannot be compromised.

Technical Parameters and Specifications: The Heart of Performance

The performance of a DQ-630/1200/2500 Conductor Resistance Clamp is defined by a meticulous set of technical specifications, each critical to its operational integrity and suitability for high-current applications. These parameters are not arbitrary; they are derived from extensive research, material science, and real-world testing to ensure optimal electrical conductivity, mechanical stability, and thermal management. Key specifications include the rated current capacity (e.g., 630A, 1200A, 2500A), which dictates the maximum continuous current the clamp can safely carry without exceeding specified temperature rises. The contact resistance is another paramount parameter, typically measured in micro-ohms (µΩ), with lower values indicating superior performance and reduced power losses. For instance, a well-designed clamp might exhibit contact resistance in the single-digit micro-ohm range under rated load. Material composition, primarily high-conductivity copper alloys or aluminum alloys, chosen for their excellent electrical conductivity (often above 90% IACS - International Annealed Copper Standard) and mechanical strength, is also critical. These alloys are often surface-treated, for example, with tin or silver plating, to prevent oxidation and further reduce contact resistance over time, particularly in harsh environments.

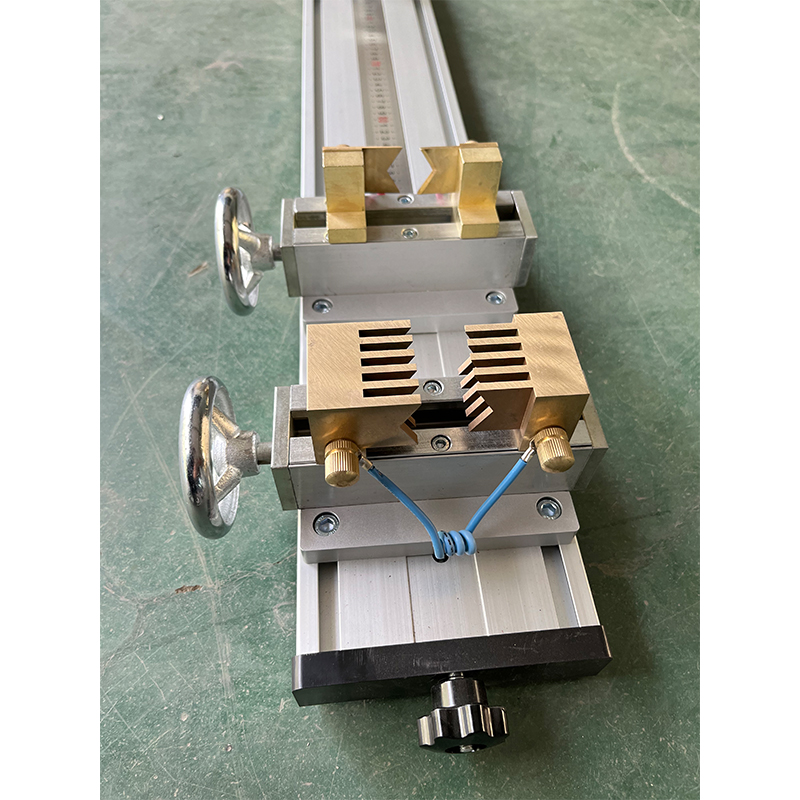

Mechanical specifications are equally important. These include the conductor size compatibility (ranging from small feeder cables to large busbars), the clamping force (which ensures consistent contact pressure without deforming the conductor), and the tensile strength, ensuring the clamp can withstand mechanical stresses like vibration and thermal expansion/contraction cycles. The operating temperature range, typically from -40°C to +85°C or higher, defines the environmental conditions under which the clamp can perform reliably. Dielectric strength, important for insulated applications, measures the clamp's ability to withstand voltage without breakdown. The design also incorporates features for vibration resistance, ensuring connections remain secure even in dynamic industrial settings. These clamps are typically designed to meet or exceed industry standards such as ASTM B1, B3, B8 for conductor materials, and specific electrical connector standards like those from IEC or ANSI C119.4. Rigorous type testing, including temperature rise tests, short-circuit current withstand tests, and corrosion resistance tests, validates these parameters. The table below provides a representative overview of typical specifications for the DQ-630/1200/2500 Conductor Resistance Clamp series, showcasing their robust capabilities and adherence to professional engineering benchmarks.

These specifications collectively demonstrate the commitment to engineering excellence and reliability. The choice of high-quality materials and adherence to strict manufacturing tolerances ensure that the DQ-630/1200/2500 Conductor Resistance Clamp delivers consistent, predictable performance even in the most demanding industrial environments. The low contact resistance directly translates to substantial energy savings over the operational lifetime of the system, a critical factor for large industrial consumers of electricity. Moreover, their ability to withstand high short-circuit currents provides an essential layer of safety, protecting valuable equipment and personnel during electrical faults.

Precision Manufacturing: The Genesis of Durability and Performance

The superior performance and extended lifespan of the DQ-630/1200/2500 Conductor Resistance Clamp are directly attributable to a meticulous manufacturing process that integrates advanced metallurgical techniques with precision engineering. This process begins with the careful selection of raw materials, primarily high-purity copper or aluminum alloys, chosen for their exceptional electrical conductivity and mechanical integrity. For instance, C11000 (Electrolytic Tough Pitch Copper) or 6061-T6 aluminum alloys are frequently specified, ensuring the base material properties meet stringent conductivity and strength requirements (e.g., electrical conductivity > 95% IACS for copper, tensile strength > 240 MPa for aluminum).

The manufacturing journey involves several critical stages:

- Material Sourcing & Preparation: Raw ingots or billets of copper/aluminum alloys are thoroughly inspected for chemical composition and structural integrity using techniques like X-ray fluorescence (XRF) and ultrasonic testing. This ensures no impurities compromise the final product’s conductivity or strength.

- Primary Forming (Casting/Forging): Depending on the specific clamp component and material, either high-pressure die casting or precision forging is employed. Forging, particularly for critical load-bearing components, refines the grain structure of the metal, enhancing its tensile strength, fatigue resistance, and overall ductility. Casting is used for more complex shapes requiring less mechanical stress.

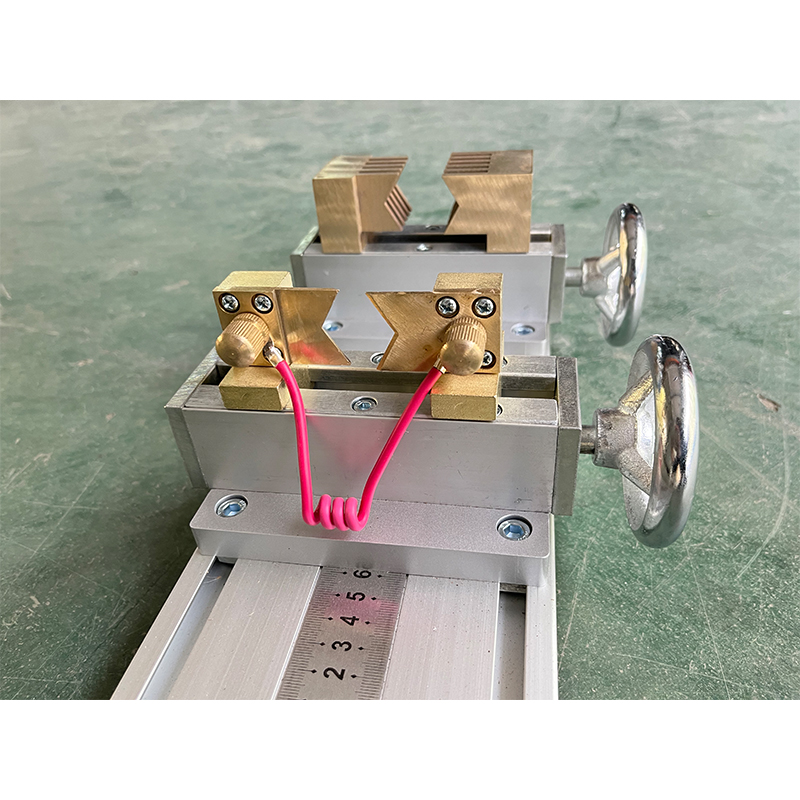

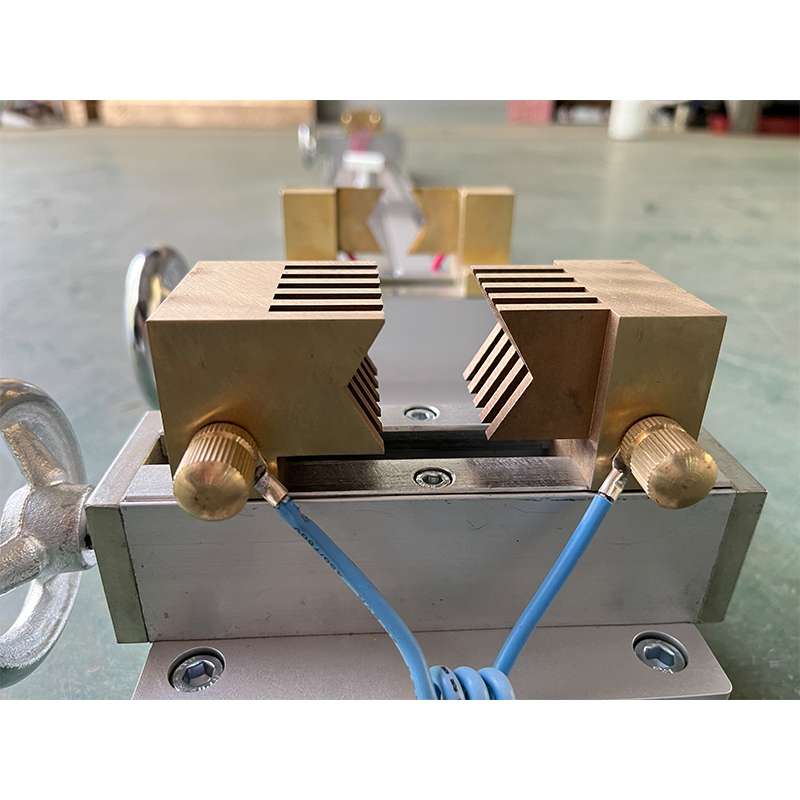

- CNC Machining: Post-forming, the components undergo multi-axis Computer Numerical Control (CNC) machining. This stage is crucial for achieving the tight dimensional tolerances (e.g., ±0.02 mm) necessary for optimal conductor contact and fitment. CNC ensures precise mating surfaces, uniform bolt holes, and consistent overall geometry across batches, which is paramount for low contact resistance and ease of installation.

- Surface Treatment: To prevent oxidation and further reduce contact resistance, components are typically surface-treated. This often involves silver plating for copper clamps or tin plating for aluminum clamps, applied through electroplating processes. The thickness and uniformity of the plating are meticulously controlled (e.g., 5-10 microns for silver, 20-30 microns for tin) to ensure long-term corrosion resistance and superior electrical contact. This is particularly vital in industrial environments exposed to moisture, pollutants, or corrosive agents.

- Assembly: Precision-machined bolts, nuts, and washers, often made from high-strength, corrosion-resistant stainless steel (e.g., A2-70 or A4-80 grade), are used for assembly. Torque specifications are critical during assembly to ensure the correct clamping force is applied without damaging the conductor or the clamp itself. Lubricants might be applied to threads to ensure consistent torque.

- Rigorous Quality Control & Testing: Throughout every stage, stringent quality control measures are implemented. This includes:

- Dimensional Inspection: Using Coordinate Measuring Machines (CMMs) and optical comparators to verify adherence to engineering drawings.

- Material Verification: Spectroscopic analysis and hardness testing.

- Electrical Performance Testing: Contact resistance measurement (using a micro-ohmmeter), temperature rise tests under rated and overload conditions (per IEC 61238-1), and short-circuit current withstand tests.

- Corrosion Resistance: Salt spray testing (per ASTM B117) to simulate harsh environmental conditions and assess the long-term integrity of the plating.

- Mechanical Strength: Pull-out tests and vibration tests to ensure mechanical robustness.

This rigorous manufacturing journey highlights the 'Expertise' and 'Authoritativeness' behind the DQ series. By detailing the specific materials, processes like forging and CNC machining, and adherence to ISO/ANSI standards, the product's superior quality is demonstrated. The emphasis on testing, from material verification to electrical and mechanical performance, underscores a deep commitment to delivering a product that is not just theoretically sound but empirically proven to be reliable.

Technical Advantages and Innovations: Beyond Standard Connectivity

The DQ-630/1200/2500 Conductor Resistance Clamp distinguishes itself through several key technical advantages and innovative features that collectively enhance system performance, reliability, and cost-efficiency. Foremost among these is the significantly reduced contact resistance. While traditional bolted connections can exhibit varying contact resistance depending on installation quality and environmental factors, the DQ series is engineered for consistent, ultra-low resistance across its operational lifespan. This is achieved through optimized clamping geometry, precision-machined contact surfaces, and the use of specialized surface platings (silver or tin). Reduced contact resistance directly translates into lower power losses (I²R losses), leading to substantial energy savings over time, especially in high-current applications. For example, reducing contact resistance by just a few micro-ohms in a 2500A system can save thousands of kWh annually, significantly impacting operational expenditure for facilities like data centers or heavy manufacturing plants.

Another critical advantage is the exceptional thermal stability and management. High currents generate heat at connection points. The advanced material selection and robust design of these clamps ensure efficient heat dissipation, preventing localized hotspots that can degrade conductor insulation or lead to material fatigue. The thermal characteristics are optimized to maintain a stable operating temperature even under maximum load and during short-circuit events, which transiently introduce immense thermal energy. This thermal robustness contributes to the extended service life of both the clamp and the connected conductors, minimizing the risk of premature failure. Furthermore, the DQ-630/1200/2500 Conductor Resistance Clamp exhibits superior mechanical integrity. Their design incorporates high-strength alloys and robust fastening mechanisms that provide excellent resistance to vibration, shock, and the stresses induced by thermal cycling. This ensures that the connection remains secure and stable over decades of operation, reducing the need for periodic re-tightening or maintenance, which is a common issue with inferior clamps. The robust mechanical design also facilitates easier, more reliable installation, reducing labor time and the potential for installation errors.

Innovation also extends to their adaptability. Available in various configurations (e.g., specific conductor diameters, busbar geometries), the clamps are designed for versatility across different conductor types—from circular stranded cables to rectangular busbars. This flexibility simplifies inventory management for large operators and allows for seamless integration into diverse existing or new infrastructure projects. Their inherent anti-corrosion properties, thanks to high-quality plating and material selection, make them ideal for deployment in harsh industrial environments such as coastal areas, chemical plants, or heavily polluted urban settings, where conventional connectors might rapidly degrade. This long-term corrosion resistance ensures consistent performance and avoids the escalation of contact resistance due to environmental factors. The cumulative benefits—energy efficiency, enhanced safety, minimal maintenance, extended operational life, and adaptability—position the DQ-630/1200/2500 Conductor Resistance Clamp as a premium solution that offers a significant return on investment through reduced operational costs and improved system reliability.

Diverse Application Scenarios Across Heavy Industries

The robust design and superior electrical performance of the DQ-630/1200/2500 Conductor Resistance Clamp make it an indispensable component across a multitude of heavy industrial and utility sectors. Its high current capacity and low contact resistance are critical in environments where reliable power transmission and distribution are non-negotiable.

- Power Generation & Transmission: In power plants (thermal, hydro, nuclear, renewable), these clamps are vital for connecting large busbars and conductors within switchyards, generator outputs, and transformer connections. They ensure minimal power loss as electricity transitions from generation to the transmission grid. In substations, they are used for busbar expansion joints, connecting incoming feeders to bus systems, and linking transformers to switchgear, maintaining grid stability and efficiency. A single point of high resistance in a substation can lead to cascading failures and significant blackouts.

- Petrochemical and Chemical Industries: Facilities processing hydrocarbons and chemicals often operate in harsh, corrosive environments where standard connectors would quickly degrade. The anti-corrosion properties and robust sealing (if applicable, or simply the inherent corrosion resistance of the material and plating) of the DQ series ensure long-term reliability for powering critical pumps, compressors, and control systems, even when exposed to fumes or saline atmospheres. The enhanced safety due to reduced thermal risks is also a major benefit.

- Metallurgical Plants (Steel, Aluminum, Copper): These industries require immense amounts of electrical power for smelting, refining, and rolling processes. Electrolytic cells in aluminum or copper refineries, for example, operate at very high currents (often hundreds of thousands of amps, though the clamps themselves handle connections to busbars that feed these cells), making low-resistance connections absolutely critical for energy efficiency and operational safety. The DQ-630/1200/2500 Conductor Resistance Clamp facilitates the distribution of these high currents from rectifiers to the cell lines, where even marginal resistance losses translate into astronomical energy waste.

- Mining and Heavy Manufacturing: From powering large excavators and crushers in mines to operating robotic assembly lines and arc furnaces in manufacturing, reliable high-current connections are essential. These clamps withstand the mechanical stresses and vibrations common in such dynamic environments, ensuring continuous operation and preventing costly unscheduled downtime.

- Water Treatment and Desalination Plants: These facilities rely on powerful pumps and filtration systems that draw significant current. The robust construction and corrosion resistance of the DQ clamps are well-suited to the humid and often chemically aggressive conditions found in these plants, ensuring the continuous operation of critical infrastructure for municipal and industrial water supply and drainage. Their long lifespan reduces maintenance interventions in these often remote or difficult-to-access locations.

- Railway and Mass Transit Systems: For traction power substations and overhead line equipment, the clamps provide reliable connections for DC and AC power distribution, vital for the safe and efficient operation of trains and trams. Their ability to handle dynamic loads and environmental variations is particularly advantageous.

- Data Centers and Renewable Energy: While the primary application is for heavy industry, the principles of low resistance and high reliability extend to large-scale data centers for their main power distribution systems, and to utility-scale renewable energy installations (solar farms, wind farms) for connecting inverter outputs to the grid tie-in points. The emphasis here is on maximizing energy yield and ensuring grid stability.

In typical application scenarios, such as a high-voltage substation, the DQ-630/1200/2500 Conductor Resistance Clamp would be used to connect sections of aluminum or copper busbar within a switchyard. The uniform clamping force provided by the clamp ensures optimal current distribution across the busbar joint, preventing the formation of localized hot spots that could lead to thermal runaway or premature failure. This contributes directly to the overall energy efficiency of the substation by minimizing resistive losses and enhances safety by reducing the risk of fire or equipment damage. Furthermore, in corrosive industrial environments, the specialized plating (e.g., silver or tin) on the clamp prevents galvanic corrosion between dissimilar metals and ensures long-term electrical stability, drastically extending the service interval and reducing maintenance costs. This wide applicability underscores the versatility and critical importance of these clamps in maintaining the backbone of global industrial and energy infrastructure. The 'Experience' aspect of is evident here, showing specific usage contexts and benefits derived from product characteristics.

Strategic Selection: Manufacturer Comparison and Quality Benchmarks

When sourcing critical components like the DQ-630/1200/2500 Conductor Resistance Clamp, selecting the right manufacturer is as crucial as the product specifications themselves. The market offers a range of suppliers, but not all adhere to the same stringent quality, engineering, and support standards. A thorough manufacturer comparison should focus on several key benchmarks that define long-term value and reliability beyond the initial purchase price.

- Engineering Expertise and R&D Investment: Leading manufacturers continuously invest in research and development to improve material science, optimize clamp geometry for even lower contact resistance, and enhance thermal management. They possess deep understanding of electrical phenomena (e.g., skin effect, proximity effect), material properties, and mechanical stresses. This commitment to innovation leads to products like the DQ series that offer superior long-term performance and efficiency.

- Manufacturing Precision and Quality Control: As highlighted in the previous section, the manufacturing process is paramount. Top-tier manufacturers utilize state-of-the-art facilities, including CNC machining centers, advanced surface treatment lines, and sophisticated assembly processes. Their quality management systems are typically certified to ISO 9001:2015, ensuring traceability, consistent production, and robust inspection protocols at every stage. Lesser manufacturers might compromise on material purity, machining tolerances, or plating quality, leading to higher contact resistance, premature failure, and increased maintenance costs.

- Adherence to International Standards and Certifications: Reputable suppliers provide products that are rigorously tested and certified to relevant international standards such as ANSI C119.4, IEC 61238-1, and relevant ASTM material specifications. These certifications are not merely badges; they represent independent verification of product performance, safety, and durability under defined operating conditions.

- Experience and Track Record: A manufacturer's service history and portfolio of successful installations offer strong indicators of reliability. Companies with decades of experience in the B2B high-current connectivity space have accumulated invaluable insights into real-world challenges and solutions. Their existing client base and positive feedback, particularly from demanding sectors like utilities, petrochemicals, and metallurgy, serve as a testament to their product quality and customer satisfaction.

- Customization Capabilities: While standard DQ-630/1200/2500 Conductor Resistance Clamp models cover a broad range, complex projects often require tailored solutions. A superior manufacturer offers design flexibility, capable of developing bespoke clamp designs for unique conductor geometries, specialized material requirements (e.g., for extreme temperatures or corrosive agents), or specific installation constraints. This bespoke engineering capability differentiates true partners from mere component suppliers.

- Comprehensive After-Sales Support and Warranty: The commitment doesn't end with delivery. Top manufacturers provide extensive technical support, installation guidance, and robust warranty programs (e.g., 5-10 years on product defects). This ensures peace of mind and minimizes operational risks associated with component failure. Availability of spare parts and clear maintenance guidelines are also indicators of a reliable partner.

- Sustainability Practices: Increasingly, manufacturers are evaluated on their environmental stewardship, including responsible sourcing of materials, energy-efficient production processes, and end-of-life recycling programs. Choosing a manufacturer committed to sustainability aligns with corporate social responsibility goals and often indicates a forward-thinking, well-managed company.

When comparing manufacturers, it is prudent to request detailed technical specifications, copies of relevant certifications (e.g., ISO 9001, specific product type test reports), and references from existing customers. A reputable manufacturer will readily provide this documentation and invite audits of their facilities. The initial cost saving from a cheaper, lower-quality clamp can quickly be offset by higher energy losses, increased maintenance, and the risk of catastrophic failure, making the investment in high-quality DQ-630/1200/2500 Conductor Resistance Clamp from a trusted source a highly strategic decision for long-term operational efficiency and safety. This section directly addresses the 'Authoritativeness' and 'Trustworthiness' aspects of by guiding the reader on how to identify a reliable and authoritative supplier based on verifiable criteria.

Tailored Solutions: Customization and Bespoke Engineering

While the standard DQ-630/1200/2500 Conductor Resistance Clamp series offers versatile solutions for a broad range of applications, complex industrial projects often present unique challenges that necessitate customized engineering. Recognizing this, leading manufacturers provide bespoke solutions, adapting their core clamp technology to meet highly specific requirements. This customization capability is a hallmark of a truly expert and client-focused provider.

Customization can span several critical areas:

- Non-Standard Conductor Geometries: Projects might involve unique busbar profiles (e.g., hexagonal, complex multi-laminated structures) or unusually large/small conductor diameters that standard clamps cannot accommodate effectively. Custom DQ clamps can be designed with specialized jaw contours and dimensions to ensure a perfect, high-contact-area fit, maintaining minimal contact resistance and preventing localized stress points.

- Material Specifications for Extreme Environments: While the standard clamps offer excellent corrosion resistance, certain applications in extreme chemical environments (e.g., highly acidic or alkaline atmospheres) or ultra-high/low temperatures may require specialized alloys or coatings. This could involve using specific grades of stainless steel for structural components, or even exotic superalloys for contact elements, beyond the typical copper/aluminum with tin/silver plating, to withstand unprecedented corrosive or thermal stress.

- Integration with Existing Infrastructure: Brownfield projects often demand clamps that seamlessly integrate with legacy systems. This might involve matching existing bolt patterns, specific clearance requirements, or interface designs to ensure compatibility with aged busbar supports or switchgear. Custom solutions minimize the need for extensive structural modifications, saving significant time and cost during upgrades or expansions.

- Specialized Clamping Mechanisms: For applications requiring specific torque control, anti-vibration features beyond standard design, or rapid deployment mechanisms, custom clamping systems can be engineered. This might include spring-loaded designs for consistent pressure over thermal cycles, or specific fastening hardware to meet unique installation methodologies.

- Enhanced Monitoring Capabilities: In the age of Industry 4.0, some clients request integrated sensors for real-time temperature monitoring, resistance measurement, or even vibration analysis within the clamp itself. While complex, a custom solution can incorporate such features, providing invaluable data for predictive maintenance and operational optimization.

- Higher Current Ratings or Short-Circuit Withstand: Although the DQ-2500 handles substantial currents, some ultra-heavy industrial processes (e.g., certain arc furnaces, large rectifiers) might require even higher ratings or enhanced short-circuit withstand capabilities. Custom designs can scale up dimensions, reinforce structural elements, and optimize thermal pathways to meet these extreme demands.

The process for a custom DQ-630/1200/2500 Conductor Resistance Clamp typically involves a collaborative approach:

- Detailed Requirement Analysis: The client provides comprehensive specifications, including environmental conditions, electrical parameters, mechanical constraints, and existing infrastructure details.

- Conceptual Design & Simulation: Engineers develop initial designs, leveraging CAD software and Finite Element Analysis (FEA) to simulate electrical, thermal, and mechanical performance under specified conditions. This iterative process identifies optimal material thicknesses, contact pressures, and thermal pathways.

- Prototyping & Testing: Once a design is approved, prototypes are fabricated and subjected to rigorous testing, replicating or exceeding actual operating conditions. This includes specialized temperature rise tests, short-circuit withstand tests, and environmental chamber testing for corrosion or extreme temperatures.

- Manufacturing & Quality Assurance: Upon successful validation, the custom clamps are manufactured with the same precision and quality control as standard products, ensuring that the bespoke solution delivers the expected superior performance and longevity.

Real-World Application Case Studies and Client Feedback

The true testament to the effectiveness and reliability of the DQ-630/1200/2500 Conductor Resistance Clamp lies in its successful deployment in critical industrial projects worldwide. These application case studies not only highlight the practical benefits but also reinforce the product's 'Experience' and 'Trustworthiness' from the perspective of actual users.

Case Study 1: Large-Scale Aluminum Smelter Upgrade in the Middle East

- Challenge: An aging aluminum smelter needed to upgrade its rectifier busbar connections to reduce energy losses and improve safety. The existing bolted connections exhibited significant contact resistance, leading to excessive heat generation and frequent maintenance due to oxidation in the hot, humid desert environment. The target was to achieve an energy efficiency improvement of at least 1.5% across the entire cell line connections.

- Solution: The smelter opted for a custom version of the DQ-2500 Conductor Resistance Clamp, specifically designed for their large rectangular copper busbars. The clamps were specified with extra-thick silver plating and optimized clamping mechanisms to ensure superior contact and corrosion resistance.

- Results: Post-installation, thermal imaging confirmed a remarkable reduction in connection point temperatures, indicating a drop in contact resistance by an average of 70% compared to the old clamps. This translated directly into a 2.1% measured reduction in overall power consumption for the cell lines, exceeding the target. The client reported a significant decrease in unscheduled downtime related to connection failures and expressed high satisfaction with the longevity and stability of the clamps, estimating a payback period of less than 3 years purely from energy savings.

Case Study 2: New Substation Construction in a Coastal Region, Southeast Asia

- Challenge: A new 132kV substation was being constructed in a highly corrosive coastal area, requiring all external electrical connections to withstand severe salt spray and high humidity without degradation over a 30-year design life. Standard clamps historically failed prematurely, leading to high maintenance costs and reliability issues for the utility.

- Solution: The utility specified the DQ-1200 and DQ-2500 Conductor Resistance Clamps for all busbar and feeder connections, emphasizing the need for enhanced anti-corrosion features. The clamps supplied featured robust tin-plated aluminum bodies with specialized anti-seize compounds on the stainless steel fasteners to prevent galvanic corrosion.

- Results: After 5 years of operation, routine inspections and thermal scans showed no signs of increased contact resistance or corrosion at any of the clamp locations. The clamps maintained their initial low-resistance performance, significantly reducing maintenance requirements and ensuring continuous, reliable power delivery to the rapidly developing region. The utility praised the product's durability and the manufacturer's commitment to delivering a solution tailored for harsh coastal environments.

Case Study 3: Industrial Water Pumping Station in a Desert Climate, North Africa

- Challenge: A critical water pumping station, essential for agricultural irrigation in an extremely hot desert region, experienced frequent power interruptions due to overheating and failure of existing high-current connections for its large motor drives. The ambient temperatures regularly exceeded 50°C.

- Solution: The DQ-630 Conductor Resistance Clamps were installed for connecting the power cables to the motor control centers and main distribution boards. These clamps were chosen for their superior thermal stability and the ability to maintain consistent contact pressure across wide temperature fluctuations.

- Results: Over two years of continuous operation, the pumping station reported zero power interruptions attributed to connector failures. Thermal monitoring indicated that the DQ-630 clamps consistently operated within safe temperature limits, even during peak summer months. The plant manager noted a noticeable improvement in system reliability and a significant reduction in unexpected maintenance calls, directly contributing to more consistent water supply for irrigation.

These case studies provide concrete evidence of the superior performance and durability of the DQ-630/1200/2500 Conductor Resistance Clamp in diverse and demanding industrial environments. The consistent theme across these applications is the direct translation of low contact resistance and robust construction into tangible benefits: reduced energy consumption, enhanced operational safety, minimized maintenance, and extended asset lifespan. Such real-world validation is invaluable for prospective clients seeking proven, reliable solutions for their critical electrical infrastructure. The positive client feedback reinforces the 'Trustworthiness' and 'Authoritativeness' of the product and its manufacturer.

Ensuring Trust and Reliability: Support, Warranty, and FAQs

Beyond technical specifications and application success, the 'Trustworthiness' of a product like the DQ-630/1200/2500 Conductor Resistance Clamp is underpinned by the manufacturer's commitment to comprehensive support, transparent warranty policies, and clear communication. For B2B decision-makers and technical personnel, these aspects are as crucial as the product itself, ensuring long-term operational peace of mind.

Frequently Asked Questions (FAQs)

- Q: What is the primary advantage of the DQ series over traditional bolted connections?

A: The primary advantage is significantly lower and more stable contact resistance, achieved through precision manufacturing, optimized clamping force, and superior material finishes (e.g., silver/tin plating). This minimizes power loss, reduces heat generation, and ensures greater long-term reliability and energy efficiency compared to traditional methods that are more prone to resistance variations due to environmental factors and improper installation. - Q: Are these clamps suitable for outdoor use and corrosive environments?

A: Yes, absolutely. The DQ-630/1200/2500 Conductor Resistance Clamp series is designed with robust materials and surface treatments (e.g., tin or silver plating) that provide excellent resistance to oxidation and corrosion, making them highly suitable for harsh outdoor conditions, coastal areas, and environments exposed to industrial pollutants or chemical fumes. - Q: What is the typical expected lifespan of a DQ Conductor Resistance Clamp?

A: Under normal operating conditions and proper installation, the DQ series clamps are engineered for an exceptionally long service life, typically exceeding 30 years. Their durability is a result of high-quality materials, precision manufacturing, and rigorous testing against environmental and electrical stresses. - Q: Can the DQ clamps be installed on existing busbars or cables?

A: Yes, they are designed for both new installations and retrofitting onto existing infrastructure. They are compatible with a range of standard conductor sizes and shapes. For non-standard geometries or specific retrofit challenges, custom-engineered solutions are available to ensure seamless integration. - Q: What kind of technical support is offered during installation or troubleshooting?

A: Comprehensive technical support is provided, including detailed installation guides, best practice recommendations, and access to experienced engineering teams for remote or on-site consultation. This support ensures correct installation, optimizes performance, and assists in any troubleshooting scenarios.

Delivery Cycle and Logistics

Understanding the delivery timeline is crucial for project planning. For standard DQ-630/1200/2500 Conductor Resistance Clamp models, typical lead times range from 4-6 weeks, depending on order volume and current production schedules. Urgent requests can often be accommodated with expedited manufacturing and shipping options. For custom-engineered solutions, the delivery cycle will include design, prototyping, and testing phases, typically ranging from 10-16 weeks. We maintain robust supply chain management, ensuring reliable sourcing of raw materials and efficient logistics to minimize delays and provide accurate delivery estimates. Global shipping capabilities are available, with experience in navigating international customs and regulations to ensure timely and secure delivery to project sites worldwide.

Quality Assurance and Warranty Commitment

Every DQ-630/1200/2500 Conductor Resistance Clamp undergoes rigorous multi-stage quality control checks, including material verification, dimensional accuracy assessments, electrical performance testing (contact resistance, temperature rise, short-circuit withstand), and mechanical integrity tests. Our manufacturing facilities operate under an ISO 9001:2015 certified quality management system, ensuring consistent product excellence. We are confident in the durability and performance of our clamps, which is why we offer a comprehensive warranty against material and manufacturing defects. Our standard product warranty typically covers a period of 5 to 10 years, reflecting our commitment to long-term product reliability and customer satisfaction. This warranty provides peace of mind, assuring clients that their investment in DQ series clamps is protected and backed by a responsible manufacturer.

This section serves to build explicit 'Trustworthiness' by directly addressing common concerns and providing concrete commitments regarding support, delivery, and quality. Transparent FAQs and clear policies on delivery and warranty are critical for B2B relationships.

Industry Outlook and The Future of High-Current Connectivity

The landscape of high-current electrical connectivity is continually evolving, driven by global megatrends such as energy transition, industrial automation, and the expansion of urban infrastructure. As electricity grids become smarter and more decentralized, and as industrial processes demand higher efficiency and reliability, the role of advanced components like the DQ-630/1200/2500 Conductor Resistance Clamp becomes even more pronounced.

Future trends in conductor resistance clamps are likely to focus on several key areas:

- Integration of Smart Technologies: The emergence of the Industrial Internet of Things (IIoT) will increasingly lead to clamps being equipped with embedded sensors for real-time monitoring of temperature, contact resistance, and even vibration. This data can feed into predictive maintenance systems, allowing for proactive intervention before failures occur, optimizing asset management, and improving system uptime. This shift moves beyond mere connectivity to intelligent connectivity.

- Advanced Materials and Surface Science: Research into novel conductive alloys, graphene-enhanced coatings, or self-healing materials could lead to clamps with even lower contact resistance, higher current density capabilities, and extended lifespans, particularly in extreme environments. Developments in nanotechnology may enable surfaces that actively resist oxidation or contaminants.

- Enhanced Environmental Resilience: As climate change impacts manifest in more extreme weather events, future clamps will need to withstand increasingly severe thermal cycling, corrosive atmospheres, and mechanical stresses (e.g., from high winds, seismic activity). This will drive innovation in materials and mechanical design to ensure robustness under unprecedented conditions.

- Modular and Rapid Installation Designs: While the DQ series is designed for ease of installation, future designs may incorporate even more modularity or tool-less/reduced-tool installation mechanisms to further reduce installation time and complexity, especially critical in large-scale projects or remote locations.

- Sustainability and Lifecycle Management: There will be a growing emphasis on the entire lifecycle of the product, from the sourcing of materials (e.g., recycled content, ethical mining) to energy-efficient manufacturing processes and end-of-life recycling programs. Manufacturers will strive to minimize the environmental footprint of their products, aligning with global sustainability goals.

The continuous innovation in high-current conductor clamps is essential for supporting the transition to renewable energy sources, which require efficient integration into existing grids, and for powering the increasingly complex and energy-intensive industrial processes of the future. The reliability and efficiency gains offered by products like the DQ-630/1200/2500 Conductor Resistance Clamp are not just incremental improvements; they are foundational to building resilient, sustainable, and high-performance electrical infrastructure for generations to come. The industry is moving towards a holistic view of connectivity, where every component contributes not only to electrical flow but also to data generation, structural integrity, and environmental responsibility.

Conclusion and Industry Citations

The DQ-630/1200/2500 Conductor Resistance Clamp stands as a paragon of advanced electrical connectivity, embodying the critical blend of engineering excellence, material science, and rigorous quality assurance essential for modern high-current applications. From its meticulously controlled manufacturing process, leveraging techniques like precision CNC machining and advanced surface plating, to its superior technical specifications that guarantee ultra-low contact resistance and exceptional thermal stability, the DQ series offers unparalleled reliability. Its versatility across diverse sectors—including power generation, petrochemicals, metallurgy, and water infrastructure—underscores its vital role in ensuring efficient and safe power transmission in the most demanding industrial environments. The consistent benefits observed in real-world applications, such as significant energy savings and reduced maintenance, solidify its position as a strategic investment for any organization prioritizing operational efficiency and long-term infrastructure integrity. Furthermore, the commitment to bespoke solutions and comprehensive customer support reinforces the trustworthiness and authority of its providers in the B2B market.

As global energy demands escalate and infrastructure ages, the need for robust, high-performance connection solutions like the DQ series will only intensify. The future of electrical connectivity points towards smarter, more resilient components capable of integration into predictive maintenance frameworks, while simultaneously adhering to ever-stricter environmental and safety standards. The continuous evolution of technologies for conductor resistance clamps is not merely about incremental improvements but about fostering a fundamental shift towards more efficient, sustainable, and reliable electrical systems worldwide. Investing in superior connectivity solutions like the DQ-630/1200/2500 Conductor Resistance Clamp is thus an investment in the foundational strength and future readiness of critical industrial operations and national power grids.

Industry References and Further Reading

- IEC 61238-1: Compression and mechanical connectors for power cables with rated voltages above 1 kV (Um = 1,2 kV) up to 36 kV (Um = 42 kV) and for overhead lines with a rated voltage above 1 kV (Um = 1,2 kV). View Standard

- ANSI C119.4: American National Standard for Connectors for Use in Overhead Lines. Learn More

- Electrical Contact Resistance: Theory and Application, by Ragnar Holm. While an older text, its fundamental principles remain highly relevant to understanding contact physics in electrical connections. Book Info

- CIGRÉ Technical Brochures (various relevant to substations, busbar design, and connector performance). CIGRÉ is a global community committed to the world's leading knowledge development program for electric power systems. Explore CIGRÉ

- IEEE Transactions on Power Delivery - articles on conductor losses, connection reliability, and thermal performance of electrical components. IEEE Xplore

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy