dumbbell cutter companies

The Rise of Dumbbell Cutter Companies Innovations in Precision Cutting Technology

In recent years, the manufacturing and construction industries have witnessed the emergence of numerous specialized companies focusing on precision cutting technologies. Among these, dumbbell cutter companies have carved out a unique niche that responds to the growing demand for accurate, efficient, and versatile cutting solutions. This article will explore the significance of dumbbell cutters, the innovative companies behind this technology, and their impact on various industries.

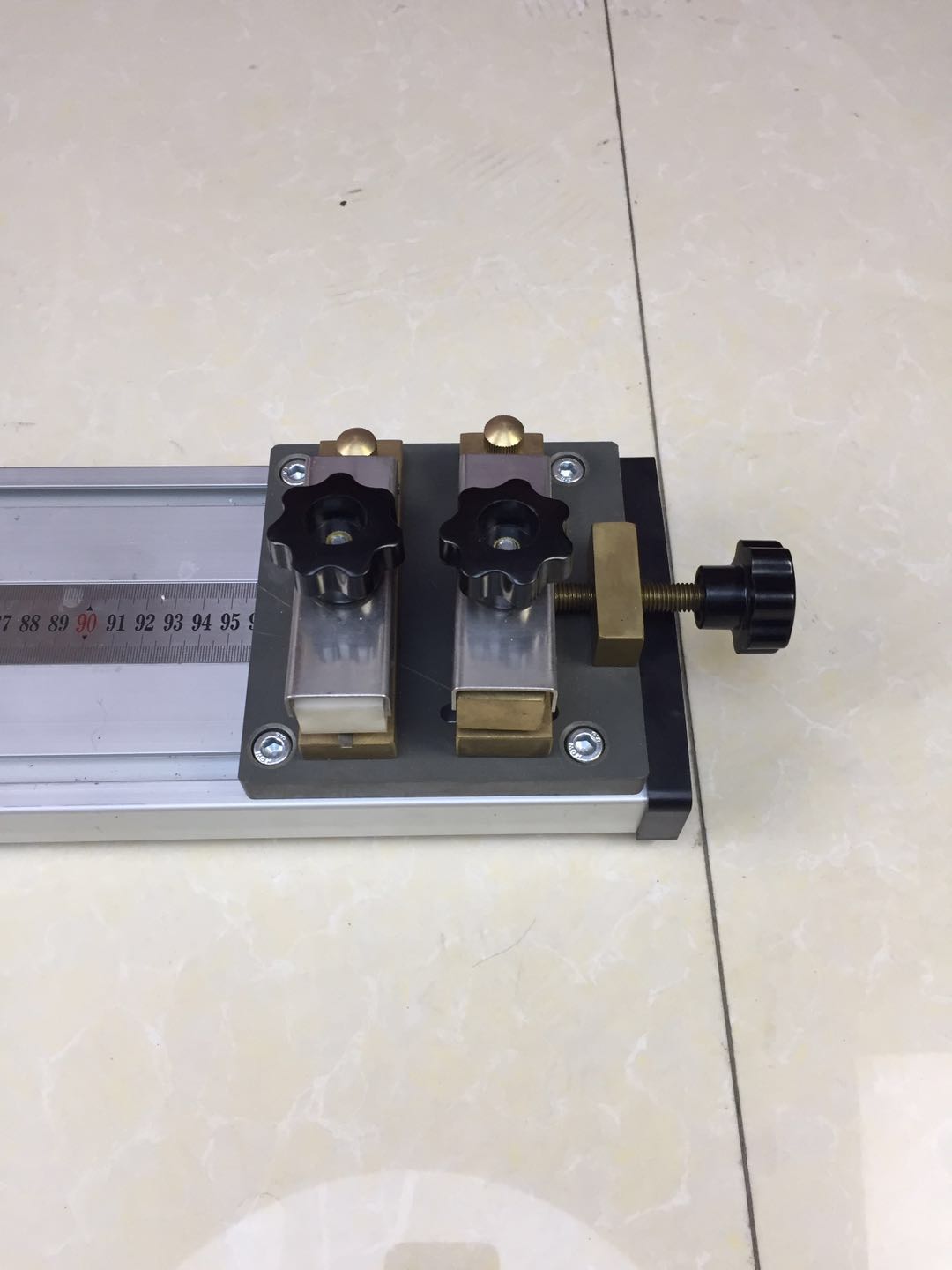

Understanding the Dumbbell Cutter

At its core, a dumbbell cutter is a specialized tool designed to cut materials with precision, often used in settings ranging from metal fabrication to construction and even in artistic applications. The name “dumbbell” originates from the tool’s shape, which typically resembles a dumbbell with two weights connected by a narrow bar, allowing for enhanced maneuverability and cutting efficiency.

Dumbbell cutters are particularly favored for their ability to slice through tough materials while maintaining accuracy. They are used for cutting rods, pipes, and sheets of metal, making them indispensable in industries such as automotive manufacturing, aerospace, and construction. Their ability to create clean cuts reduces material waste and enhances the overall efficiency of production processes.

Key Players in the Dumbbell Cutter Market

The market for dumbbell cutters has seen the emergence of several companies that prioritize innovation and quality. These companies focus on developing cutting-edge technologies that enhance the performance and durability of their products. One notable company is CuttingTech Innovations, renowned for its commitment to research and development. By continually refining the design and materials used in their dumbbell cutters, they have achieved remarkable improvements in cutting speed and precision.

Another significant player is Precision Tools Corp., which specializes in manufacturing customized dumbbell cutters tailored to specific industry needs. Their expertise in material science allows them to create cutters that are not only effective but also long-lasting, minimizing downtime for businesses that rely on these tools.

dumbbell cutter companies

Impact on Industries

The contributions of dumbbell cutter companies extend beyond just providing tools; they play a crucial role in shaping industry standards. By pushing for advancements in cutting technology, these companies have enabled businesses to improve their productivity and reduce costs. Industries that utilize dumbbell cutters benefit from the high-quality finishes and tight tolerances achieved through modern cutting techniques.

Moreover, the environmental impact of manufacturing processes has become a focal point in recent years. Dumbbell cutter companies are stepping up to meet these concerns by developing eco-friendly cutting solutions. These innovations reduce waste and energy consumption during the cutting process, aligning with the global goal of sustainability.

The Future of Dumbbell Cutters

Looking forward, the future of dumbbell cutter companies appears promising. With the advent of smart technologies and automation, the next generation of dumbbell cutters will likely incorporate features such as advanced sensors and connectivity options. This integration will allow for real-time monitoring and adjustments, optimizing cutting processes further.

In addition, as industries continue to evolve, there will be an increasing demand for versatility in cutting tools. Dumbbell cutter companies that can adapt to various materials and cutting scenarios will be well-positioned for growth in this dynamic market.

Conclusion

Dumbbell cutter companies are making significant strides in the manufacturing and construction sectors by providing innovative, precise cutting solutions. Their impact resonates across industries, promoting efficiency, sustainability, and quality. As technology continues to evolve, these companies will undoubtedly play a crucial role in shaping the future of precision cutting, ensuring they remain integral to industry advancements.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy