dumbbell cutter suppliers

Understanding Dumbbell Cutter Suppliers A Comprehensive Overview

In the world of industrial manufacturing and materials processing, the tools we use can significantly influence efficiency, accuracy, and overall productivity. Among these tools, dumbbell cutters have emerged as essential devices for a range of applications. As industries evolve, the demand for high-quality, durable, and efficient cutting tools has led to a burgeoning market for dumbbell cutter suppliers.

What is a Dumbbell Cutter?

Dumbbell cutters, also known as dumbbell-shaped cutters, are specialized tools used primarily for cutting materials like metal, plastic, and other composites. Their unique shape allows for enhanced maneuverability and precision during cutting operations. These tools are particularly favored in industries such as automotive, aerospace, construction, and metalworking, where intricate cuts are frequently required.

The design of a dumbbell cutter typically features a tapered end, which aids in reducing material wastage and improving cutting accuracy. This tool can be fitted onto various machinery, including CNC machines and manual lathes, which adds to its versatility in different operational environments.

The Growing Demand for Dumbbell Cutters

As industrial needs change and expand, so does the demand for specialized cutting tools. Industries are continuously seeking innovative solutions to improve productivity and reduce operational costs. This drive towards efficiency has led to an increase in the usage of dumbbell cutters, as they provide several advantages over traditional cutting methods.

Firstly, dumbbell cutters are often more efficient in terms of speed and material consumption. Their design allows for faster cutting and less waste, which can translate into significant cost savings for manufacturers. Secondly, precision is a crucial aspect of any cutting operation. The unique shape of dumbbell cutters minimizes the risk of errors during the cutting process, ensuring a more accurate end product.

Choosing the Right Dumbbell Cutter Supplier

dumbbell cutter suppliers

With the increasing demand for these cutting tools, the number of suppliers in the market has also risen. However, as with any product, not all suppliers are created equal. When selecting a dumbbell cutter supplier, several factors should be considered.

1. Quality of Products The most crucial aspect to evaluate is the quality of the dumbbell cutters. High-quality tools are made from durable materials that can withstand wear and tear, which not only prolongs their lifespan but also guarantees consistent performance.

2. Range of Products A good supplier should offer a comprehensive range of dumbbell cutters, including various sizes and designs to cater to different industrial needs. This variety ensures that clients can find a tool that perfectly matches their specific requirements.

3. Customer Support and Service Excellent customer service is a key indicator of a reliable supplier. Suppliers that provide solid support, including assistance with selection, usage, and after-sales care, can significantly enhance the overall experience for their clients.

4. Reputation and Reviews Researching a supplier’s reputation can provide insight into their reliability and product quality. Reading reviews and testimonials from other customers can help gauge their level of service and the performance of their products.

5. Technological Integration As industries continue to innovate, suppliers that integrate modern technologies into their products will likely offer superior performance. Suppliers that invest in research and development to improve their cutting tools can provide enhanced features and better solutions for their clients.

Conclusion

In conclusion, dumbbell cutters are indispensable tools in modern industrial applications, offering unique advantages in terms of efficiency and precision. The increasing demand for these tools has paved the way for a variety of suppliers in the market. By evaluating product quality, range, customer support, reputation, and technological advancements, businesses can find a reliable supplier that meets their cutting needs. As industries continue to innovate, the role of suppliers in providing high-quality dumbbell cutters will remain vital for enhancing productivity and efficiency in manufacturing processes. The right partnership can lead to significant improvements in both operational success and competitive edge.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

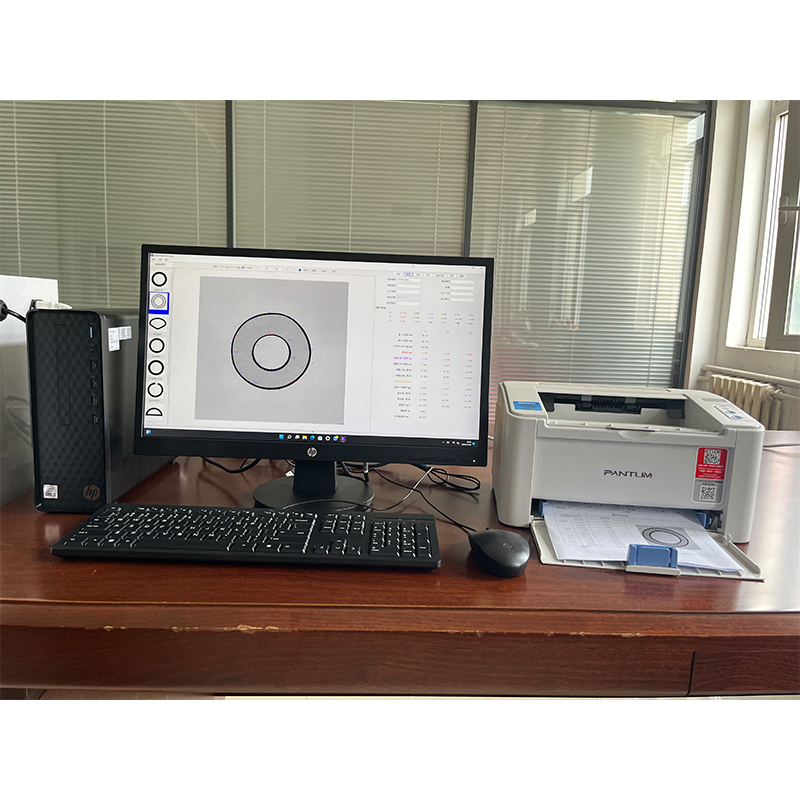

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy