dumbbell die cutter manufacturer

The Importance of Choosing the Right Dumbbell Die Cutter Manufacturer

In the realm of manufacturing and die-cutting, the right equipment can make a significant difference in production efficiency and end product quality. Among the various options available, the dumbbell die cutter stands out for its unique capabilities and versatility. This article explores the importance of choosing a reliable dumbbell die cutter manufacturer and the factors to consider in making a selection.

Understanding Dumbbell Die Cutters

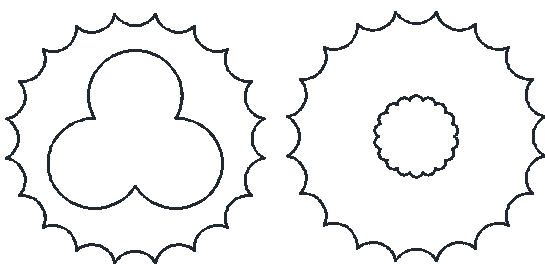

Dumbbell die cutters are specialized machines designed to cut materials into specific shapes with high precision. The term dumbbell refers to the typical shape of the die used in these machines, which resembles a dumbbell. These cutters are widely employed in industries ranging from textiles to packaging, making them an essential tool for manufacturers who need to produce finely detailed designs and shapes.

One of the core advantages of using a dumbbell die cutter is the ability to achieve clean cuts and intricate designs. This capability is particularly important in sectors where aesthetic appeal and functional design are critical, such as fashion accessories, custom packaging, and automotive parts. As consumers increasingly demand high-quality products with unique designs, the role of dumbbell die cutters becomes even more vital.

The Role of the Manufacturer

The choice of a dumbbell die cutter manufacturer can significantly impact the efficiency, durability, and performance of the equipment. A quality manufacturer will offer machines that not only meet your production needs but also exceed your expectations. Here are some key factors to consider when selecting a dumbbell die cutter manufacturer

A manufacturer's reputation in the industry is often a reflection of their product quality and customer service. Companies with extensive experience in manufacturing die-cutting equipment typically have a proven track record of delivering reliable and innovative machines. Researching customer reviews, industry accolades, and the manufacturer’s history can provide valuable insights.

2. Technology and Innovation

dumbbell die cutter manufacturer

With advancements in technology, modern dumbbell die cutters come equipped with features that enhance their efficiency and usability. It's essential to choose a manufacturer that embraces innovation and integrates the latest technologies into their products. Features such as automated cutting systems, user-friendly interfaces, and energy-efficient designs can greatly improve production processes.

3. Customization Options

Different industries have unique requirements when it comes to die cutting. A good manufacturer will offer customization options to ensure that their die cutters can meet specific needs. This can include adapting the size of the die, the material compatibility, and the software integration capabilities. Customized solutions can optimize production lines and lead to better end products.

4. Customer Support and Service

The support you receive before and after purchasing a dumbbell die cutter is crucial. A reliable manufacturer should provide extensive customer service, including installation assistance, troubleshooting, and maintenance services. Having access to knowledgeable support can minimize downtime and ensure that your operations run smoothly.

5. Pricing and Warranty

While cost shouldn't be the only consideration, it's important to evaluate the pricing of dumbbell die cutters in relation to their features and benefits. A higher price might reflect better quality, advanced technology, and extended warranties. Understanding warranty terms can also give you peace of mind about your investment.

Conclusion

Choosing the right dumbbell die cutter manufacturer is paramount for businesses looking to enhance their production capabilities and product quality. By focusing on reputation, technology, customization, customer support, and pricing, manufacturers can find the best solutions tailored to their specific needs. As industries continue to evolve, the demand for high-quality die-cutting solutions will only increase, making it essential to partner with a manufacturer who is not only reliable but also innovative in its approach. Ultimately, the right equipment from the right manufacturer can lead to improved efficiency, enhanced product offerings, and greater customer satisfaction.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy