electrical insulation resistance tester factory

Understanding the Importance of Electrical Insulation Resistance Tester Factories

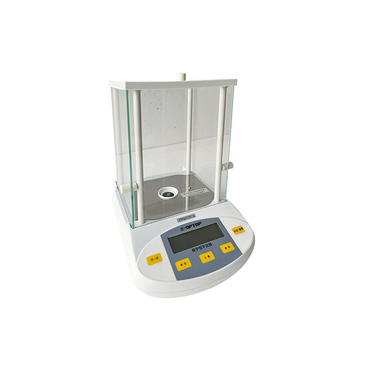

Electrical insulation resistance testers are fundamental instruments in the realm of electrical safety and performance. These devices are primarily used to ensure that electrical systems are properly insulated, which is crucial for preventing electrical shocks, equipment damage, and compromising safety standards. As industries evolve and energy demands grow, the need for high-quality insulation resistance testers has surged, enhancing the role of factories dedicated to their manufacturing.

The Role of Electrical Insulation Resistance Testers

An electrical insulation resistance tester measures the resistance offered by electrical insulation materials. By applying a specified voltage, usually in the range of 250V to 5000V, these testers determine how well insulation is functioning. High resistance readings indicate good insulation, while low readings may suggest potential defects or degradation in the insulation material. Regular testing and monitoring help in identifying issues before they lead to catastrophic failures.

Factory Overview Manufacturing Excellence

Factories that specialize in the production of electrical insulation resistance testers are equipped with advanced technology and expertise. They focus on several key elements to ensure the testers are reliable, accurate, and durable.

1. Quality Control Manufacturing these testers requires rigorous precision and quality assurance processes. Factories implement strict quality control protocols to ensure that each instrument meets the required standards, such as IEC 61557 for electrical safety equipment. Consistent testing of components and finished products is critical to reliability.

2. Research and Development Innovation is at the heart of modern manufacturing. R&D teams in these factories strive to enhance the performance of insulation testers. This involves integrating new technologies, such as digital displays, improved circuit designs, and enhanced capabilities that allow for quicker and more accurate readings.

electrical insulation resistance tester factory

3. Sustainable Practices Many manufacturers are now adopting sustainable practices in their operations. This includes using recyclable materials, reducing waste during production, and optimizing energy consumption in their manufacturing processes. These initiatives not only contribute to environmental protection but also appeal to increasingly eco-conscious consumers.

4. Customization Different industries have varied requirements when it comes to insulation resistance testing. Manufacturers are increasingly offering customized solutions to meet specific needs, such as higher voltage testing capabilities or multifunctional devices that combine insulation resistance measurement with other parameters like continuity testing and earth resistance measurement.

The Market Demand

The demand for electrical insulation resistance testers is driven by a multitude of factors. The rising awareness of workplace safety, stringent regulations regarding electrical installations, and the increase in infrastructure projects worldwide all contribute to this demand. Industries such as manufacturing, construction, and renewable energy are particularly reliant on these testing instruments to ensure compliance and operational safety.

As companies seek to maintain their safety standards and protect their investments, the need for reliable testing equipment becomes paramount. Industries increasingly depend on regular inspections using insulation resistance testers to ensure that electrical systems are functioning as intended, thereby reducing the risk of accidents and costly downtimes.

Conclusion

As the electrical landscape continues to evolve, the significance of electrical insulation resistance tester factories is undeniable. These specialized manufacturing sites are crucial in producing high-quality instruments that enhance safety and efficiency in electrical systems. With a focus on quality control, innovation, sustainability, and customization, they play a vital role in meeting market demands and advancing electrical safety standards.

In summary, understanding the operations and importance of electrical insulation resistance tester factories equips us with knowledge about the broader implications of electrical safety in our daily lives. As technology progresses, these factories will likely continue to refine their manufacturing processes and product offerings, further solidifying their place in the industry while ensuring that electrical systems remain safe and efficient.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy