electrical insulation resistance tester manufacturer

The Evolution and Importance of Electrical Insulation Resistance Testers in Modern Industry

In today's digital age, where the demand for reliable electrical systems is paramount, the significance of electrical insulation resistance testers cannot be overstated. As industries increasingly depend on electric power, ensuring the safety and efficiency of electrical installations has become a top priority. This article delves into the evolution, functionality, and importance of these essential testing devices, shedding light on manufacturers' role in advancing their technology.

Understanding Electrical Insulation Resistance Testing

Electrical insulation resistance testers are specialized instruments used to measure the insulation resistance of electrical equipment and systems. They provide a means of assessing the integrity of insulation materials, thereby preventing potential electrical failures that can lead to serious hazards, such as electrical shocks, equipment damage, and fires. These testers work by applying a high voltage to the insulation and measuring the resulting current flow, which indicates the condition of the insulation. A higher resistance reading typically signifies better insulation quality and reliability.

The Evolution of Insulation Resistance Testers

The history of insulation resistance testers dates back to the early 20th century when electrical safety standards were first introduced. Initially, these testers were rudimentary, relying on basic resistance measurement techniques. However, as technology advanced, manufacturers began developing more sophisticated testing devices, incorporating enhanced features and better user interfaces.

Today, insulation resistance testers are available in various forms, including handheld devices, portable testers, and advanced bench-top models. Modern testers feature digital displays, programmable settings, and connectivity options for data logging and analysis. The integration of microprocessors and software has revolutionized the testing process, allowing for more accurate measurements, easier data interpretation, and improved user experience.

Key Features of Modern Insulation Resistance Testers

When selecting an insulation resistance tester, several features should be considered to ensure it meets the specific requirements of the application. Some key features include

electrical insulation resistance tester manufacturer

2. Auto-Test Functions Many advanced models come equipped with automatic test functions that streamline the testing process, reducing the time and effort required to obtain accurate readings.

3. Data Logging The ability to record and store test results is a significant advantage for professionals who need to track the performance of their electrical systems over time. This feature aids in compliance with safety regulations and maintenance schedules.

4. User-Friendly Interfaces A clear display and intuitive controls make modern testers accessible even to those with limited experience. Guided test sequences and built-in help features enhance usability.

5. Durability and Portability Given that insulation testing often occurs in various environments, testers are designed to be rugged, portable, and able to withstand harsh conditions, ensuring reliability on-site.

The Role of Manufacturers in Advancing Technology

Manufacturers play a crucial role in the continued development of electrical insulation resistance testers. They invest in research and development to innovate new technologies that enhance the performance and capabilities of these testing devices. Collaborations with industry experts, feedback from end-users, and advancements in materials science contribute to the creation of more efficient and reliable testers.

Moreover, manufacturers ensure compliance with international safety standards, which is essential for creating products that professionals can trust. They also offer comprehensive support and training resources to help users maximize the benefits of their testing equipment.

Conclusion

As industries strive to maintain high safety and efficiency standards in electrical systems, the role of electrical insulation resistance testers will only grow more critical. The evolution of these testers—from basic models to sophisticated, multifunctional devices—highlights the continuous advancements in technology that manufacturers are championing. By investing in quality insulation resistance testers, businesses can ensure the safety of their electrical installations, ultimately contributing to a safer and more reliable future for all.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

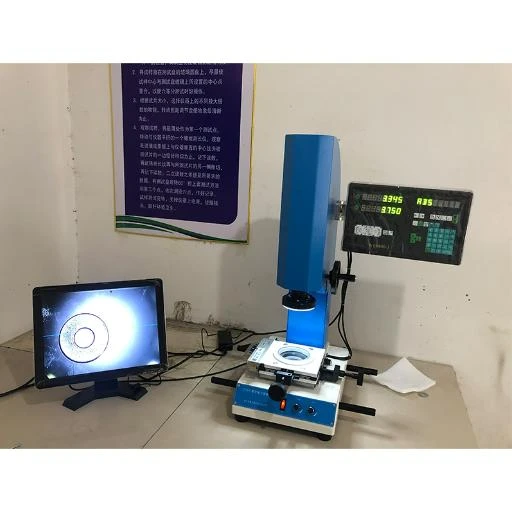

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy