electrical resistivity clamps manufacturer

Understanding the Importance of Electrical Resistivity Clamps A Focus on Manufacturers

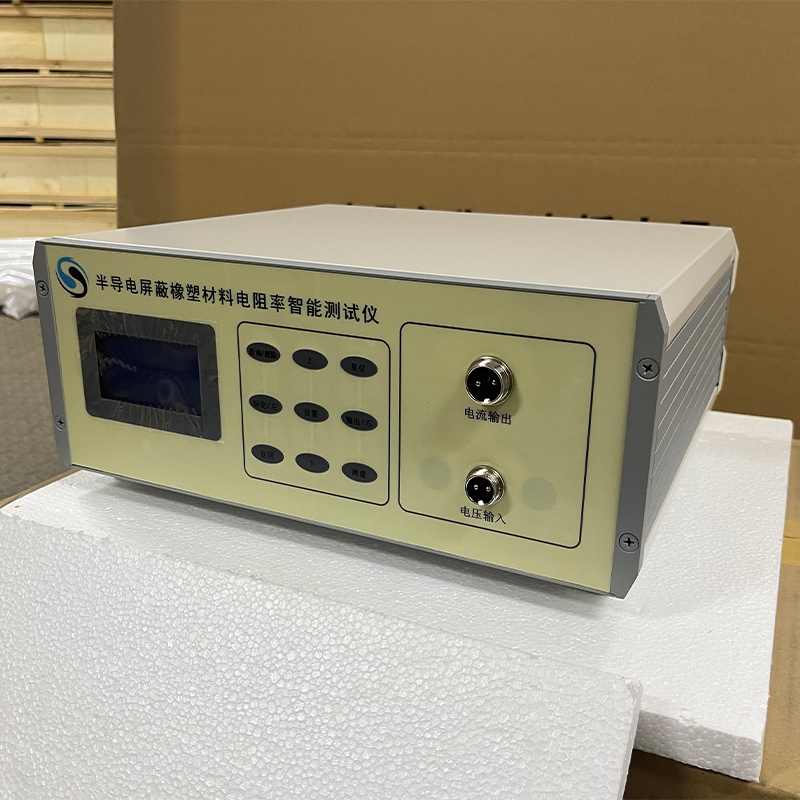

In the world of electrical engineering, precision and reliability are paramount. One of the critical components that contribute to ensuring these qualities is the electrical resistivity clamp. This device is integral to measuring the resistivity of various materials, which is essential for assessing the quality and performance of electrical systems. As technology advances, the demand for high-quality electrical resistivity clamps has surged, leading to a proliferation of specialized manufacturers.

What are Electrical Resistivity Clamps?

Electrical resistivity clamps are sophisticated devices used to measure the resistivity of materials, typically in soil and concrete. The resistivity of a material indicates how strongly it opposes the flow of electric current; thus, this measurement is vital for applications in construction, environmental engineering, and utility services. The data provided by these clamps helps engineers design reliable electrical systems, manage grounding systems, and ensure the stability of structures.

Features of Quality Electrical Resistivity Clamps

When selecting an electrical resistivity clamp, it is crucial to consider several features that can impact the performance and accuracy of the measurements. Some of the key attributes include

1. Accuracy and Precision High-quality clamps ensure precise measurements, which are critical for effective analysis and decision-making in engineering projects. 2. Durability The materials used in the construction of these clamps should be robust enough to withstand harsh environmental conditions, ensuring longevity and reliability.

3. Ease of Use User-friendly designs can significantly enhance efficiency in the field. Intuitive interfaces and easy-to-read displays can help technicians conduct tests quickly and effectively.

4. Versatility The ability to measure a wide range of materials and settings enhances the adaptability of the clamps in various scenarios, making them invaluable tools for engineers.

electrical resistivity clamps manufacturer

The Role of Manufacturers in Advancing Technology

Manufacturers of electrical resistivity clamps play a critical role in advancing technology. Leading companies in this field invest heavily in research and development to create innovative products that meet the evolving needs of their clients. They often collaborate with engineers, scientists, and industry experts to enhance the functionality of their devices.

These manufacturers also focus on providing comprehensive customer support, which includes training, troubleshooting, and guidance on best practices for measurement. This support is vital, as incorrect use of equipment can lead to erroneous results that can have significant ramifications in projects.

Choosing the Right Manufacturer

When looking to purchase electrical resistivity clamps, it’s essential to choose a manufacturer with a solid reputation for quality and reliability. Potential buyers should consider factors such as

- Experience and credentials Established manufacturers with a proven track record are more likely to produce high-quality equipment.

- Product reviews and testimonials Feedback from previous customers can provide insights into the product's performance and the manufacturer's customer service.

- Warranty and support services A solid warranty and good after-sales support can be indicators of a manufacturer’s confidence in their product quality.

In summary, electrical resistivity clamps are indispensable tools in the electrical engineering field, providing critical data that informs design and safety considerations. The choice of manufacturer can significantly influence the effectiveness of these devices. By focusing on quality, durability, and customer service, reliable manufacturers ensure that engineers have the tools necessary to create safe and efficient electrical systems. As technology continues to evolve, the collaboration between manufacturers and engineers will be key to pushing the boundaries of what is possible in the realm of electrical resistivity measurement.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy