electrode resistivity tests supplier

Understanding Electrode Resistivity Tests A Guide for Suppliers

In the realm of electrical engineering and materials science, electrode resistivity tests play a crucial role in assessing the performance and suitability of conductive materials. These tests measure how easily an electric current can pass through a given material, providing important insights for various applications including electronics, construction, and materials manufacturing. For suppliers in this field, understanding the significance and intricacies of these tests is fundamental to delivering quality products and ensuring client satisfaction.

What are Electrode Resistivity Tests?

Electrode resistivity tests are conducted to determine the electrical resistivity of materials, particularly those intended for use in electrical conductors or electrodes. Resistivity, measured in ohm-meters, indicates how strongly a material opposes the flow of electric current. Materials with low resistivity are excellent conductors, while those with high resistivity are insulators. The tests often involve inserting electrodes into the material and measuring the voltage drop over a known current to calculate the resistivity using Ohm’s law.

Importance of Electrode Resistivity Tests

1. Quality Assurance For suppliers, conducting thorough resistivity tests ensures that the materials meet industry standards and client specifications. This is especially critical in sectors where performance is paramount, such as in the manufacturing of batteries, semiconductor devices, and conductive coatings.

2. Material Selection Understanding the resistivity of various materials helps suppliers recommend the most suitable products for specific applications. For example, metals like copper and aluminum are preferred for wiring due to their low resistivity, while high-resistivity materials may be better suited for insulation.

3. Predicting Performance Electrode resistivity tests assist in predicting how materials will behave under different electrical loads. This predictive capability allows suppliers to address potential issues before the materials are put into practical use, reducing the risk of failure.

4. Regulatory Compliance Many industries operate under strict regulatory frameworks that mandate specific electrical properties of materials. Regular resistivity testing helps suppliers ensure compliance with these regulations, thus avoiding legal complications and enhancing product credibility.

electrode resistivity tests supplier

Techniques Used in Electrode Resistivity Testing

There are several methods employed in resistivity testing, including

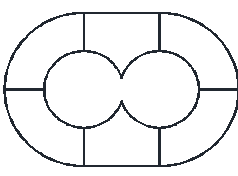

- Two-Probe Method This straightforward technique measures the resistance of a material using two electrodes. It is most effective for homogeneous samples but can produce errors for non-uniform samples.

- Four-Probe Method This more advanced technique uses four equally spaced probes, which eliminates contact resistance and provides a more accurate resistivity measurement. It is ideal for thin films and semiconductors.

- AC and DC Testing Depending on the application, both alternating current (AC) and direct current (DC) methods can be applied, with each offering unique insights into the material’s resistive properties.

Challenges and Considerations

While electrode resistivity tests are invaluable, suppliers must be aware of potential challenges. Environmental factors such as temperature and humidity can significantly impact resistivity readings. Additionally, sample preparation and electrode contact quality are critical to obtaining accurate results. Suppliers should ensure their testing protocols are robust and consistent to mitigate potential variables that may affect the outcomes.

Conclusion

Electrode resistivity tests are an essential component in the toolkit of suppliers dealing with conductive materials. By rigorously assessing the resistivity of their products, suppliers can guarantee quality, ensure compliance with industry standards, and ultimately enhance the reliability of their offerings. As technology and applications evolve, staying informed about the latest testing methods and materials science advancements will position suppliers as leaders in the market, ready to meet the growing demands of their customers.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy