electromechanical universal tensile tester factory

The Role of Electromechanical Universal Tensile Testers in Material Testing

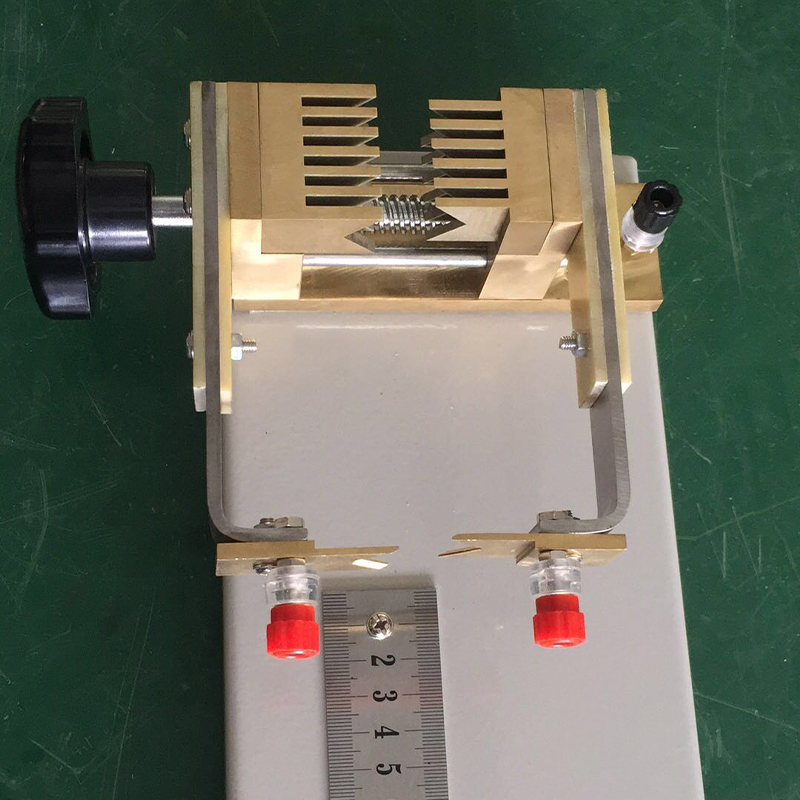

Electromechanical universal tensile testers are essential tools in the field of materials science and engineering, primarily utilized for determining the mechanical properties of various materials. These testers help assess how materials behave under tensile (stretching) loads, providing critical data for quality control, product development, and research applications across numerous industries.

Understanding Electromechanical Universal Tensile Testers

Electromechanical universal tensile testers employ an electromechanical drive system to apply a controlled load to a test specimen, enabling precise measurement of the material’s response to stress. These testers are designed for single-axis tension and compression testing, and they can perform a variety of tests, including tensile, compression, bend, and shear tests. The versatility of these machines makes them an indispensable part of laboratories involved in material analysis.

Applications Across Various Industries

The applications of electromechanical universal tensile testers span numerous industries, including aerospace, automotive, construction, and plastics. In the aerospace sector, for instance, materials need to exhibit high strength-to-weight ratios and significant reliability. Electromechanical testers help engineers select materials that meet stringent safety and performance criteria by providing data on tensile strength, yield strength, elongation, and modulus of elasticity.

In the automotive industry, these testers are crucial for evaluating the durability of components subjected to rigorous stresses throughout their operational life

. Quality control teams utilize tensile testing to ensure that the materials used in vehicles can withstand the stresses of everyday use, including impacts and vibrations.Key Features and Advantages

The electromechanical design of these testers offers several advantages over hydraulic counterparts. Firstly, they provide a higher level of precision and repeatability in measurements due to their closed-loop control systems. The software integrated with these machines enables users to perform real-time data analysis, enhancing the accuracy of test results.

electromechanical universal tensile tester factory

Moreover, electromechanical testers are generally more user-friendly. They often come equipped with intuitive software interfaces that allow operators to set up tests quickly, select from pre-defined testing standards, and analyze results effectively. This ease of use is particularly beneficial in educational settings, where students and researchers may engage with the technology regularly.

Environmental Benefits

Another significant advantage is the potential for reduced environmental impact. Electromechanical universal tensile testers consume less power compared to hydraulic versions, resulting in lower energy costs and a smaller carbon footprint. Additionally, they typically eliminate the need for hydraulic fluids, which can pose disposal challenges and environmental hazards.

Future Directions in Material Testing

As technology continues to advance, the capabilities of electromechanical universal tensile testers are set to expand. Innovations in sensor technology and data processing are paving the way for even more detailed material characterization. For example, the integration of machine learning algorithms could enable predictive modeling of material behavior, allowing engineers to forecast how new materials will perform based on existing data.

Furthermore, the growing emphasis on sustainability and eco-friendly materials will likely increase the demand for precise testing techniques in the development of greener alternatives. As industries strive for reduced environmental impact and enhanced performance, electromechanical testers will play a critical role in supporting these initiatives.

Conclusion

In conclusion, electromechanical universal tensile testers are vital instruments in the assessment of material properties, influencing design choices and quality assurance across various industries. Their precision, versatility, and environmental benefits make them a preferred option in laboratories worldwide. As technology evolves, these testers will continue to adapt, providing unparalleled insight into the materials that shape our modern world.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy