Supplier of Electromechanical Universal Tensile Testing Machines for Material Analysis and Quality Control

The Importance of Electromechanical Universal Tensile Testers and Their Suppliers

In the realm of materials testing, electromechanical universal tensile testers play a vital role in assessing the mechanical properties of various materials, including metals, polymers, and composites. These testers are essential for quality control, product development, and research applications, allowing engineers and scientists to determine how a material behaves under tensile load.

Understanding Electromechanical Universal Tensile Testers

Electromechanical universal tensile testers operate through a precise and controlled mechanism that pulls a specimen until failure, measuring parameters such as tensile strength, elongation, and yield point. The use of electric motors ensures smooth and consistent movement, which is critical for obtaining accurate measurements. These testers also typically come equipped with advanced data acquisition systems that record the testing data in real-time, enabling users to analyze material performance efficiently.

Applications Across Industries

The versatility of electromechanical universal tensile testers makes them indispensable across various industries. In the automotive sector, for instance, they are used to test the strength and ductility of materials to ensure that they can withstand the rigors of everyday use. Similarly, in the aerospace industry, stringent testing of components is crucial for safety; thus, these testers evaluate materials that must endure extreme conditions. Other fields, such as electronics, textiles, and construction, also rely heavily on universal tensile testing to ensure the materials used in their products meet safety and reliability standards.

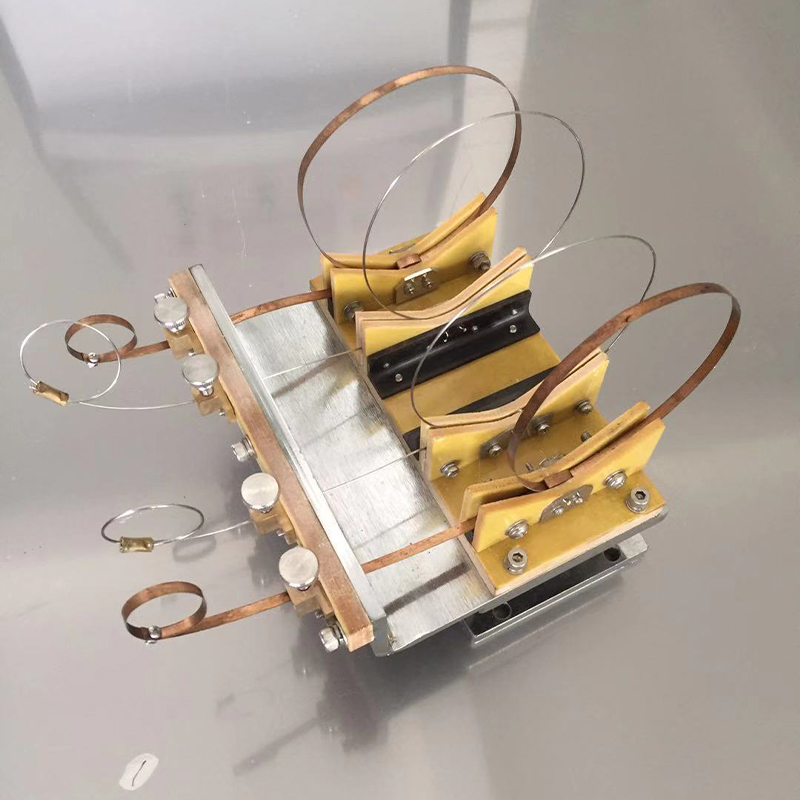

electromechanical universal tensile tester supplier

Choosing the Right Supplier

Selecting the appropriate supplier of electromechanical universal tensile testers is a critical decision for any organization. Key factors to consider include the supplier's reputation for quality, the variety of models available, and the level of technical support they provide. A reputable supplier will offer not only high-quality equipment but also calibration and maintenance services to ensure the longevity and accuracy of the testing machines.

Moreover, advanced software solutions that accompany these testers can significantly enhance their functionality. Therefore, companies should look for suppliers who provide software that can streamline data analysis and reporting processes, making it easier for teams to interpret results and implement changes based on their findings.

Conclusion

In summary, electromechanical universal tensile testers are essential tools for evaluating material properties in various industries. As businesses increasingly rely on these devices for research and quality assurance, sourcing them from reputable suppliers becomes crucial. By investing in high-quality testing equipment and robust support services, organizations can ensure the reliability of their materials, thereby enhancing their overall product quality and safety. As technology advances, the importance of these testers and their suppliers will continue to grow, leading to more innovative and resilient materials in the future.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy