Electronic Tensile Strength Testing Equipment | Precision Testing Solutions

Understanding Electronic Tensile Strength Testing Equipment and Its Importance

In the realm of material science and engineering, tensile strength testing plays a pivotal role in determining the properties of materials. One of the most advanced methods for assessing tensile strength is through the use of electronic tensile strength testing equipment. This technology has revolutionized the way we evaluate material performance, offering precision, efficiency, and a wealth of data for analysis.

Electronic tensile strength testing equipment utilizes advanced sensors and computerized systems to measure a material's resistance to being pulled apart. Unlike traditional mechanical testing machines, electronic testers provide real-time data, capturing the complete response of the material under stress. They simulate a variety of conditions to mimic real-world applications, ensuring that the material can withstand its intended use.

One of the key advantages of electronic tensile strength testing equipment is its accuracy. These machines are equipped with high-resolution load cells and displacement transducers that offer precise measurements of force and elongation. This allows for a clear understanding of the material's limits, including its yield strength, ultimate tensile strength, and elongation at break. Such detailed data is crucial for industries that rely on the integrity of materials, such as aerospace, automotive, and construction.

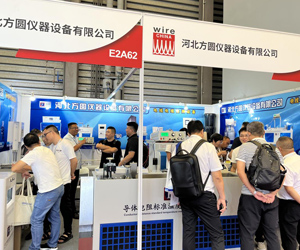

electronic tensile strength testing equipment company

Moreover, electronic tensile testers often come with advanced software that facilitates data analysis and reporting. Users can visualize stress-strain curves, derive material constants, and generate comprehensive reports with just a few clicks. This streamlines the testing process and enhances productivity, making it easier for engineers and researchers to make informed decisions about material selection and quality control.

In addition to accuracy and data management, electronic tensile strength testing equipment is also designed with user-friendliness in mind. Many models have intuitive interfaces and automated features that minimize the potential for human error. With easy-to-follow protocols, even those with limited experience can operate the equipment effectively. This accessibility makes it an invaluable tool in educational institutions as well, where students can learn about material properties in a hands-on environment.

Furthermore, as industries continue to advance towards sustainability, the significance of robust material testing grows. Electronic tensile strength testing can help in the selection of eco-friendly materials and composites, ensuring that they meet required strength and durability standards. This is increasingly important as companies strive to reduce their carbon footprints while maintaining high performance in their products.

In conclusion, electronic tensile strength testing equipment represents a significant advancement in material testing technology. Its precision, efficiency, and ease of use make it an essential tool across various industries. As we continue to innovate and push the boundaries of material science, this equipment will undoubtedly play a vital role in ensuring the performance and safety of materials in countless applications. Whether for research, quality assurance, or educational purposes, the impact of electronic tensile strength testing equipment is profound and far-reaching.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy