Electronic and Optical Measurement Devices in Manufacturing Environments and Their Applications

Electronic and Optical Measurement Instruments in Factories

In the ever-evolving landscape of modern manufacturing, the demand for precision and efficiency is paramount. This has driven the adoption of advanced electronic and optical measurement instruments in factories worldwide. These instruments play a critical role in quality control, production efficiency, and the overall competitiveness of manufacturing enterprises.

Understanding Measurement Instruments

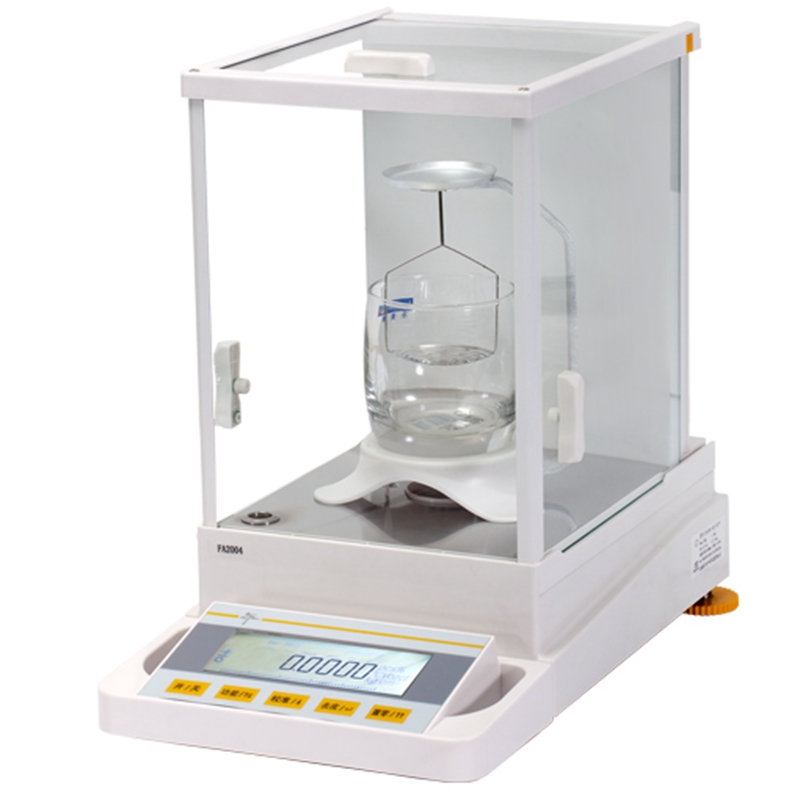

Electronic measurement instruments encompass a wide range of devices designed to measure various physical quantities such as voltage, current, resistance, temperature, and frequency. These instruments include multimeters, oscilloscopes, and spectrum analyzers, which are essential for diagnosing and troubleshooting electronic circuits and systems in factories.

On the other hand, optical measurement instruments rely on the interaction of light with matter to gather data about physical objects and phenomena. Tools such as laser scanners, optical microscopes, and spectrometers fall under this category. These instruments are crucial for inspecting surface quality, measuring dimensions, and analyzing material properties without causing damage.

Quality Assurance and Control

One of the primary applications of electronic and optical measurement instruments in factories is in quality assurance (QA) and quality control (QC). Ensuring that products meet strict quality standards is essential for maintaining customer satisfaction and reducing waste. Electronic measurement devices enable manufacturers to conduct tests on electronic components, ensuring that they operate within specified parameters.

Optical instruments provide invaluable insights into material characteristics and surface conditions. For example, the use of laser scanning techniques allows for non-contact measurement of complex geometries, enabling manufacturers to detect defects early in the production process. By integrating these measurement systems into QA/QC protocols, factories can significantly minimize defects and improve overall product quality.

electronic and optical measurement instruments factories

Enhancing Production Efficiency

Efficiency is another critical aspect where electronic and optical measurement instruments make a significant impact. By automating measurement processes, factories can reduce downtime and enhance throughput. Automated optical inspection (AOI) systems, for instance, use high-resolution cameras and sophisticated algorithms to analyze products on production lines. They can detect displacements, color discrepancies, and other anomalies that a human eye might miss.

Moreover, real-time monitoring of production variables using electronic instruments allows for data-driven decision-making. Factories can implement closed-loop control systems that adjust manufacturing processes based on real-time measurements, leading to optimized resource usage and reduced cycle times.

Future Trends

As technology continues to advance, the future of electronic and optical measurement instruments in factories is poised for considerable transformation. The integration of artificial intelligence (AI) and machine learning (ML) into measurement systems is set to revolutionize the manufacturing landscape. These technologies allow for predictive analytics, enabling manufacturers to anticipate potential issues before they arise and enhance proactive maintenance strategies.

Additionally, the rise of Industry 4.0, characterized by the interconnectivity of devices and systems, further bolsters the utility of measurement instruments. Smart factories equipped with IoT (Internet of Things) devices can collect and analyze vast amounts of data, facilitating real-time monitoring and decision-making. This integration not only enhances measurement accuracy but also contributes to increased flexibility and agility in manufacturing processes.

Conclusion

In conclusion, electronic and optical measurement instruments are indispensable assets in modern factories, driving quality assurance, production efficiency, and technological advancement. As manufacturing continues to embrace automation and connectivity, the role of these instruments will only grow in importance. Companies that invest in cutting-edge measurement technologies stand to gain a competitive edge in an increasingly global marketplace, ensuring their products meet the highest standards of quality while optimizing production processes. The future is bright for manufacturers willing to embrace these innovations as they navigate the complexities of modern production.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy