electronic tensile strength testing equipment factory

The Importance of Electronic Tensile Strength Testing Equipment in Material Science

In the field of material science and engineering, understanding the tensile strength of materials is crucial for determining their usability and integrity in various applications. Electronic tensile strength testing equipment has revolutionized how researchers and engineers evaluate the mechanical properties of materials. This article explores the significance, functionalities, and advantages of these advanced testing machines.

What is Tensile Strength?

Tensile strength is defined as the maximum amount of tensile (pulling or stretching) stress that a material can withstand before failure. It is a fundamental property that helps in assessing the strength and ductility of metals, polymers, and composites. The ability to measure this property accurately is vital in industries such as construction, manufacturing, and aerospace, where material failure can have catastrophic consequences.

The Role of Electronic Tensile Strength Testing Equipment

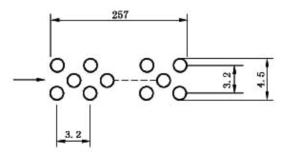

Electronic tensile strength testing machines are designed to apply controlled tension to a specimen until it fails. These modern devices are equipped with advanced sensors and software that allow for precise measurement of the force and elongation of the material throughout the test. They often come with features like load cells, extensometers, and digital readouts, which provide real-time data analysis and display.

Key Components

1. Load Cell This is a transducer that converts the applied force into an electrical signal, ensuring accurate measurement of the tensile load. 2. Extensometer This device measures the elongation of the sample, which is essential for calculating strain and assessing the material's ductility.

3. Control System Modern machines utilize sophisticated software to control the testing process, record data, and provide analytical tools for interpreting results.

4. Display Interface An easy-to-read digital interface allows operators to monitor the test in real time, making the process more user-friendly.

Advantages of Electronic Testing Equipment

electronic tensile strength testing equipment factory

2. Speed These machines can perform tests at varying speeds, allowing for a range of applications, from quick assessments to detailed analysis.

3. Data Management With capabilities for data logging and analysis, electronic systems facilitate the storage and retrieval of historical data, aiding in research and development.

4. User-Friendly Most devices come equipped with intuitive software that simplifies the testing process, allowing even less experienced operators to perform tests effectively.

5. Automation Many modern tensile testing systems can be integrated with automated systems, enhancing productivity and efficiency in laboratories and manufacturing environments.

6. Versatility Electronic tensile strength testing equipment can be used to test a variety of materials, including metals, plastics, rubber, and composites, making them indispensable in diverse fields.

Applications

The applications of electronic tensile strength testing equipment are vast. In the construction industry, structural materials undergo rigorous testing to ensure they meet safety standards. In the automotive sector, components are evaluated for durability and performance under stress. Similarly, in the aerospace industry, materials are tested for their ability to withstand extreme conditions.

Additionally, researchers use these machines in laboratories to develop new materials, investigating how various factors, such as temperature and strain rate, affect tensile strength. The advancement of electronic testing technology also contributes to the innovation of materials, enhancing their properties for specific applications.

Conclusion

Electronic tensile strength testing equipment is a cornerstone of modern materials testing. By providing accurate, fast, and comprehensive assessments of material properties, it plays a critical role in ensuring safety and performance across various industries. As technology advances, these devices will continue to evolve, further enhancing their capabilities and applications. In a world where material integrity is paramount, investing in high-quality testing equipment is not just a choice; it’s a necessity for fostering innovation and maintaining safety standards.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy