Manufacturer of Advanced Electronic Tensile Strength Testing Equipment for Precise Material Analysis

The Importance of Electronic Tensile Strength Testing Equipment Manufacturers

In the realm of material testing, the significance of electronic tensile strength testing equipment cannot be overstated. As industries continue to evolve and demand higher precision and reliability in testing, manufacturers specializing in this equipment play a crucial role in ensuring that materials meet the necessary standards for safety and performance. This article delves into the importance of these manufacturers, the technology involved in electronic tensile strength testing, and the impact of their innovations on various industries.

Understanding Tensile Strength Testing

Tensile strength is a critical property of materials, defined as the maximum amount of tensile (stretching) stress that a material can withstand before failure. This property is particularly vital in industries such as construction, manufacturing, and aerospace, where materials are subjected to various forces. Electronic tensile strength testing equipment is designed to measure this property accurately, providing insights into how materials will behave under stress.

The testing process typically involves extending a sample material until it fractures, while simultaneously measuring the force applied and the elongation produced. The data collected during this process allows engineers to determine the material’s tensile strength, yield strength, and elongation, which are essential for assessing the material’s suitability for specific applications.

Role of Manufacturers in the Industry

Manufacturers of electronic tensile strength testing equipment are at the forefront of innovation in material testing. They provide advanced machinery that incorporates the latest technology, including software integration for better data analysis and automated testing processes. Their equipment often features user-friendly interfaces, real-time data reporting, and high precision, which is essential for producing reliable results.

These manufacturers are also responsible for ensuring that their equipment meets industry standards and complies with specifications set by organizations such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). This compliance is vital for industries that must adhere to stringent safety regulations, as the accuracy of tensile strength tests can directly impact product performance and consumer safety.

Technological Advancements

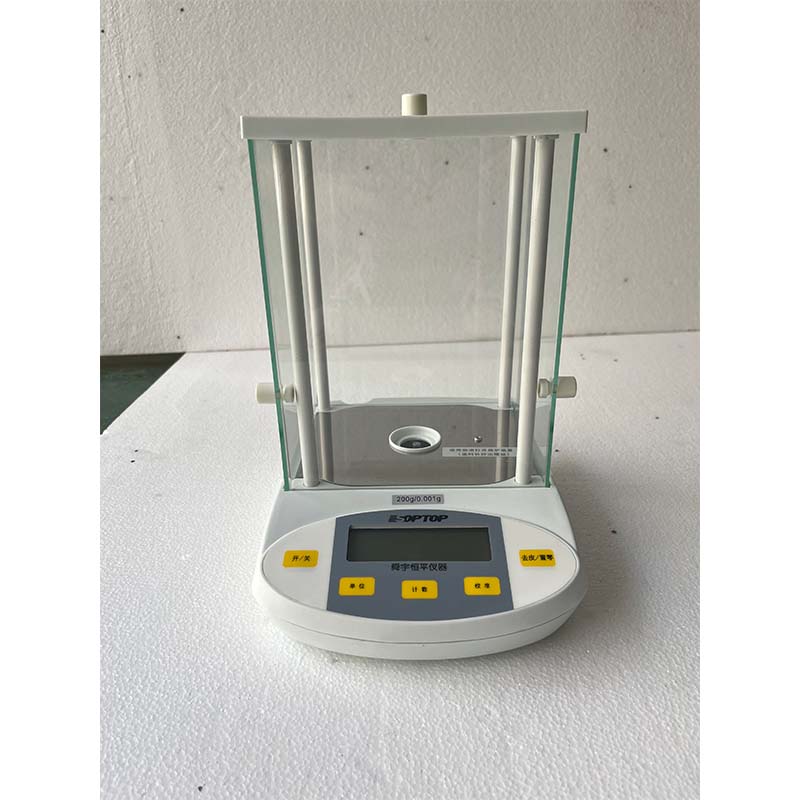

electronic tensile strength testing equipment manufacturer

Recent advancements in electronic tensile strength testing equipment have revolutionized the way materials are tested. Modern machines utilize digital load cells and advanced software algorithms to provide precise measurements while minimizing human error. Many models now offer features such as extensometers that can accurately measure elongation and a variety of test configurations suitable for different materials, including metals, plastics, and composites.

Furthermore, wireless connectivity allows for remote monitoring and data collection, enabling engineers to analyze results from anywhere. This capability not only enhances productivity but also facilitates a more comprehensive understanding of material behavior under various conditions.

Impact on Various Industries

The innovations brought forth by electronic tensile strength testing equipment manufacturers have far-reaching impacts across multiple industries. In the construction sector, for instance, the accuracy of material testing is directly tied to safety and structural integrity. Engineers can ensure that materials like steel rebar and concrete meet the required standards, thereby preventing structural failures.

Similarly, in the aerospace industry, where safety is paramount, the reliability of materials is non-negotiable. Testing equipment that provides accurate tensile strength data contributes to the development of lightweight yet strong materials that can withstand the extreme conditions encountered in flight.

In addition, the automotive industry benefits from these advancements as manufacturers strive to create vehicles that are not only fuel-efficient but also safe. By conducting thorough tensile strength tests, manufacturers can choose the right materials for critical components, ensuring longevity and performance.

Conclusion

In summary, electronic tensile strength testing equipment manufacturers play an indispensable role in various industries by providing advanced tools necessary for material testing. Their commitment to innovation, compliance with industry standards, and advancements in technology underpin the integrity and reliability of materials used in countless applications. As industries continue to advance and evolve, the demand for precise and reliable testing equipment will only grow, highlighting the enduring importance of these manufacturers in ensuring safety, performance, and quality across the board.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy