electronic tensile tester exporter

The Importance of Electronic Tensile Testers in Material Testing

In today's advanced industrial landscape, the demand for precise and reliable material testing has grown immensely. One of the essential tools in this domain is the electronic tensile tester, an instrument designed to evaluate the tensile strength of materials. As industries across the globe strive for quality assurance and compliance with rigorous standards, the role of electronic tensile testers has become increasingly significant.

Understanding Electronic Tensile Testers

Electronic tensile testers are advanced machines used to measure the strength and elongation characteristics of materials—be it metals, polymers, or textiles. These instruments work by applying a uniaxial force to a specimen until it deforms or ultimately breaks. During this process, the tester records real-time data, which allows for the calculation of various parameters such as yield strength, ultimate tensile strength, and elongation at break.

Key Features and Advantages

Modern electronic tensile testers boast several features that enhance their functionality and user experience. Digital displays, automated testing sequences, and data acquisition systems are just a few examples. These testers employ high-precision load cells and extensometers to ensure accurate results, significantly reducing the risk of human error associated with manual readings.

The advantages of using electronic tensile testers over traditional mechanical systems are manifold. Firstly, they offer more precise measurements, which are critical for applications where even minor discrepancies can lead to significant failures. Secondly, the automated nature of these machines allows for faster testing processes, which is crucial in high-throughput environments. Additionally, digital data logging provides a clear, traceable record of tests, facilitating better compliance with industry standards.

Applications Across Industries

The versatility of electronic tensile testers makes them applicable across a wide range of industries. In the automotive sector, they are instrumental in testing materials for structural components, ensuring safety and durability. In the aerospace industry, tensile testing is crucial for materials used in aircraft and spacecraft, where performance and reliability are of utmost importance.

electronic tensile tester exporter

Moreover, the construction industry relies on electronic tensile testers for evaluating materials such as steel and concrete. These tests ensure that the materials used can withstand the specific loads and stresses they will encounter during their lifecycle. The textile industry also benefits from these testers, which assess the tensile strength of fibers and fabrics, directly influencing the quality of the final products.

Global Market for Electronic Tensile Testers

The global market for electronic tensile testers is expanding, driven by technological advancements and increasing consumer awareness about product quality. As manufacturers strive for competitive advantages, investing in state-of-the-art testing equipment becomes a priority. Emerging economies are witnessing a surge in demand for these devices as industries modernize their testing processes to meet international standards.

Countries such as China, India, and Brazil present significant opportunities for exporters of electronic tensile testers. The growing manufacturing sector in these regions, combined with an increasing emphasis on quality control, is propelling the demand for reliable testing equipment. Exporters can find lucrative niches by offering tailored solutions that cater to specific industries or by providing comprehensive after-sales support and services.

Challenges in the Export Market

Despite the promising prospects, exporting electronic tensile testers comes with its challenges. One major hurdle is navigating the regulatory landscape of different countries. Compliance with international standards such as ASTM, ISO, and various local regulations is crucial for market entry. Moreover, exporters must also consider factors such as tariffs, shipping logistics, and potential language barriers that can complicate business transactions.

Another challenge is competition. As more players enter the market, standing out becomes increasingly difficult. Exporters must leverage innovative features, advanced technology, and superior customer service to differentiate their products.

Conclusion

In summary, electronic tensile testers play an integral role in the quality assurance processes of various industries, ensuring materials meet stringent performance criteria. With the continued growth of the global market, exporters of these testing devices are well-positioned to capitalize on new opportunities. By staying informed about market trends, regulatory requirements, and customer needs, businesses can thrive in this dynamic industry. Investing in technology and fostering strong customer relationships will be key to success in the competitive landscape of electronic tensile testers.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

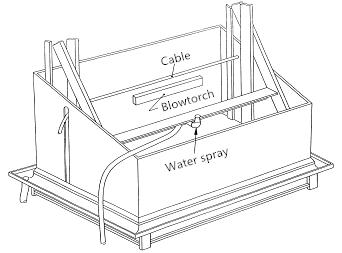

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy