electronic tensile tester factories

Understanding Electronic Tensile Tester Factories A Comprehensive Overview

The increasing demand for quality control in manufacturing industries has led to the emergence of highly specialized devices, among which the electronic tensile tester stands out. These machines are crucial for evaluating the mechanical properties of materials, particularly their tensile strength and elongation. This article provides a comprehensive overview of electronic tensile tester factories, their functions, and the significance of their products in various industries.

What is an Electronic Tensile Tester?

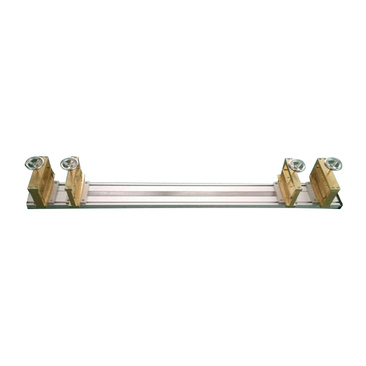

An electronic tensile tester is a sophisticated piece of equipment designed to measure the tensile properties of materials. This includes the material's yield strength, ultimate tensile strength, and elongation at break. The device typically consists of a load frame, a control panel, gripping systems, and measurement sensors. The operational principle involves applying a uniaxial load to a specimen until it fractures or breaks, allowing for the collection of essential data related to the material's performance under stress.

The Role of Electronic Tensile Tester Factories

Electronic tensile tester factories play a fundamental role in the production of these testing machines

. They are responsible for designing, engineering, and manufacturing devices catering to various sectors, including metallurgy, plastics, textiles, and more. The factories employ a combination of advanced technology and skilled labor to ensure that the testers meet stringent quality standards.1. Research and Development At the core of any electronic tensile tester factory is a robust R&D department. This team focuses on innovating new testing methodologies, improving existing technologies, and ensuring that the machines are compliant with the latest international standards. Continuous iteration and enhancement of features, such as user interfaces and data processing capabilities, are crucial to maintaining competitiveness in the market.

2. Manufacturing Process The manufacturing process of electronic tensile testers is intricate and requires precision. Factories utilize high-tech machinery and robotics to fabricate components, assembly lines for efficient production, and calibration labs to ensure accuracy. Each tester undergoes extensive testing and quality checks, where parameters like load calibration and electronic functionality are scrutinized.

electronic tensile tester factories

3. Quality Assurance Given the critical role these testers play in quality control, factories must adhere to strict quality assurance protocols. Certifications such as ISO 9001 often reflect a factory's commitment to producing reliable and accurate machines. Factories may also implement integrated management systems that monitor every stage of production, from sourcing raw materials to delivering the finished product.

4. Customer Support and Training Beyond manufacturing, electronic tensile tester factories often provide extensive customer support and training programs. Many users require guidance on operating the machinery effectively and interpreting test results. Factories may offer on-site assistance or online training modules to empower users and ensure the optimal use of their testers.

Importance of Electronic Tensile Testers in Various Industries

The significance of electronic tensile testers stretches across multiple industries. In the construction field, these machines are used to assess the tensile strength of materials such as steel and concrete, ensuring structural safety and compliance with regulatory standards. In the textile industry, tensile testing evaluates the durability of fabrics, ensuring that products meet consumer expectations.

Moreover, in the automotive sector, electronic tensile testers are vital for determining the strength of components that contribute to vehicle safety. Similarly, in the electronics industry, these testers analyze materials used in circuit boards and enclosures, ensuring that they can withstand both operational stresses and environmental conditions.

Conclusion

In conclusion, electronic tensile tester factories are vital players in the global manufacturing landscape. They contribute significantly to quality assurance, safety, and innovation across various sectors. As industries continue to evolve and adapt to new materials and technologies, the role of these factories and their products will become increasingly important in maintaining high standards of quality and performance. Understanding the complexities and operational dynamics of electronic tensile tester factories allows stakeholders to appreciate the pivotal role of these machines in ensuring the resilience and reliability of materials used in products we encounter in everyday life.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy