electronic tensile tester factory

Electronic Tensile Tester A Comprehensive Overview

In the modern industrial landscape, the significance of quality control cannot be overstated. One of the crucial tools in this domain is the electronic tensile tester. These devices are vital for assessing the mechanical properties of materials, which play a critical role in manufacturing, construction, and a variety of engineering applications. This article aims to shed light on the functions, advantages, and manufacturing processes of electronic tensile testers, commonly produced in specialized factories.

Electronic Tensile Tester A Comprehensive Overview

Factories that specialize in the production of electronic tensile testers employ advanced technologies to craft precise and efficient testing machines. These facilities often utilize computer-aided design (CAD) and computer numerical control (CNC) machining to manufacture components with high accuracy. Additionally, significant emphasis is placed on the calibration of these machines to guarantee reliable and reproducible results. The integration of electronic sensors and software systems further enhances the tester's capabilities, allowing for real-time data analysis and reporting.

electronic tensile tester factory

One of the primary advantages of electronic tensile testers over traditional mechanical testers is their ability to provide detailed feedback through digital interfaces. Many modern testers come equipped with user-friendly software that simplifies the process of data collection and analysis. This innovation not only streamlines testing procedures but also aids in the efficient management of test data, enabling quick decision-making based on empirical evidence.

Moreover, as industries move towards automation and smart manufacturing, the demand for advanced electronic tensile testers is steadily increasing. These testers are pivotal in various sectors, including aerospace, automotive, construction, and textiles, where material integrity is paramount. Ultimately, the role of electronic tensile testers in enhancing product quality and safety cannot be overstated.

In conclusion, electronic tensile testers are indispensable tools in quality control and material testing. Their precision and efficiency, backed by advanced technology and robust manufacturing techniques, make them essential for industries striving for excellence. As manufacturing continues to evolve, so too will the capabilities of electronic tensile testers, ensuring they remain at the forefront of material testing methodologies.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

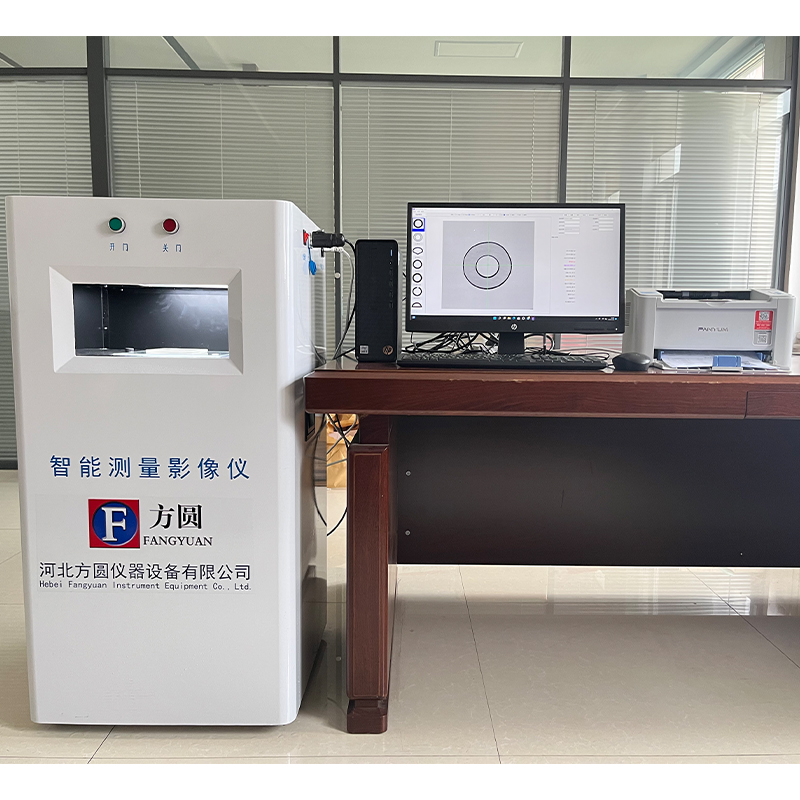

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy