electronic tensile testing machine supplier

The Role of Electronic Tensile Testing Machines in Material Science

In the realm of material science and engineering, understanding the mechanical properties of materials is crucial for product development and quality assurance. One of the most efficient methods for evaluating these properties is through the use of electronic tensile testing machines. As demand grows for reliable and precise testing solutions, numerous suppliers are emerging to provide cutting-edge technology in this area.

The Functionality of Electronic Tensile Testing Machines

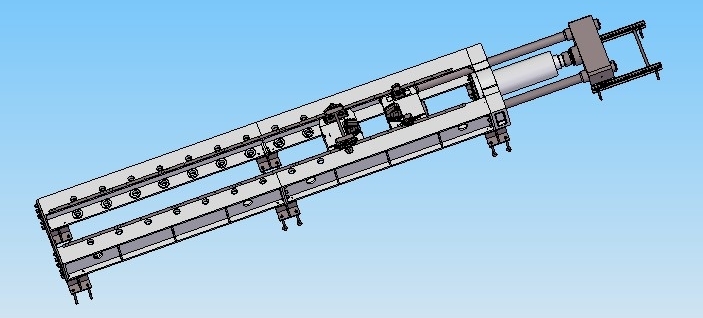

Electronic tensile testing machines are designed to apply tensile stress to a specimen — typically a piece of metal, polymer, or composite material — until it fractures or reaches a predefined limit. By measuring the material's response to increasing stress, engineers can derive key parameters such as yield strength, ultimate tensile strength, elongation, and modulus of elasticity. These machines operate with an electronic control system that provides real-time data acquisition and analysis.

The machines feature a robust frame that can withstand high forces, ensuring safety and reliability during testing. The electronic components facilitate a range of functionalities, such as programmable test speeds, automated data collection, and detailed analysis tools. Many modern systems are equipped with user-friendly software that aids in the interpretation of test results while maintaining strict compliance with international standards.

Importance in Various Industries

Electronic tensile testing machines play a pivotal role across various industries, including aerospace, automotive, construction, and manufacturing. For example, in the aerospace sector, stringent safety regulations require that materials used in aircraft manufacturing meet specific mechanical standards. Electronic tensile testing machines ensure that these materials can withstand the stress and fatigue encountered during flight.

In the automotive industry, these machines help manufacturers test components like chassis and engine parts to ensure they can endure the forces experienced in real-world conditions without failing. The construction industry similarly relies on tensile testing to verify the durability of steel rebar and other structural materials, ensuring that buildings can endure environmental stresses.

The versatility of electronic tensile testing machines also extends to research laboratories, where new materials and composites are constantly being developed

. Researchers utilize these machines to characterize materials at various temperatures, strain rates, and environmental conditions, providing valuable data for innovation and product development.electronic tensile testing machine supplier

Choosing a Suitable Supplier

When selecting a supplier for electronic tensile testing machines, several factors should be taken into consideration. First, the range of testing capacities and configurations offered is vital. Different applications require different load capacities, and a flexible supplier can provide a machine suited to specific needs.

Next, the technology used in the electronic control and data acquisition systems should be evaluated. Cutting-edge systems enable faster testing and higher precision, making them a better investment for companies committed to maintaining quality. Suppliers that offer intuitive software for data analysis and reporting can greatly enhance the overall testing experience.

Customer support and service should not be overlooked either. A reputable supplier should provide comprehensive training on operating the machine and offer technical support for troubleshooting. Additionally, ongoing calibration and maintenance services ensure that testing accuracy is maintained over time.

The Future of Electronic Tensile Testing

The future of electronic tensile testing machines looks promising, with advancements in automation and artificial intelligence (AI) paving the way for more efficient testing processes. Integration with IoT (Internet of Things) technology may lead to remote monitoring and control of testing parameters, allowing for real-time adjustments and more sophisticated data analytics.

As industries continue to prioritize safety, quality, and innovation, the role of electronic tensile testing machines will undoubtedly expand. Suppliers who invest in research and development will be at the forefront of this evolution, offering machines that meet the ever-growing demands of safety standards and material performance.

In conclusion, electronic tensile testing machines are indispensable tools in material science, contributing to the advancement of safety and quality across multiple industries. As suppliers refine their offerings and technology continues to evolve, these machines will remain crucial in the quest for reliable, high-performance materials. Whether for research or production, the right tensile testing machine can make all the difference in achieving excellence in engineering endeavors.

-

QNJ-2/3 Cable Flexibility Test Machine: Precision & Durability

NewsAug.31,2025

-

DQ-F Superfine Wire Conductor Resistance Fixture: High-Precision Testing

NewsAug.30,2025

-

ZC36 High Insulation Resistance: Reliable & Safe Performance

NewsAug.29,2025

-

CX-100 Manual Hydraulic Core Punching Machine - Efficient & Reliable

NewsAug.28,2025

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy