Top Manufacturers of Electronic Universal Tensile Testing Machines for Quality Control Solutions

Exploring Electronic Universal Tensile Testing Machine Factories

In the realm of material testing and engineering, the electronic universal tensile testing machine (EUTTM) serves as an essential instrument for evaluating the mechanical properties of various materials. These machines play a pivotal role in assessing tensile strength, elongation, and other vital characteristics, which are crucial for ensuring the safety and reliability of materials used in construction, manufacturing, and numerous other industries. The production and development of these machines are highly specialized, and understanding the factories that manufacture them can provide valuable insights into the importance of EUTTMs in modern engineering.

Electronic universal tensile testing machines operate on a simple yet effective principle they apply a controlled tensile force to a sample material until it fractures or deforms. The data collected during this process are essential for informing engineers about how materials will behave under different stress conditions. As such, factories focusing on the production of EUTTMs must employ cutting-edge technology and adhere to strict quality control standards to manufacture machines that meet industry specifications.

The manufacturing process of electronic universal tensile testing machines begins with rigorous research and development. Engineers and designers work collaboratively to create prototypes that embody the desired specifications, integrating advanced technologies such as computer numerical control (CNC) machining and digital data acquisition systems. In this stage, the focus is not only on functionality but also on user interface design to ensure that operators find the machine easy to use.

Once prototypes are tested and refined, the scale-up for mass production must take place. Factories specializing in EUTTMs utilize various automated processes to ensure consistency and precision in the production of components. High-quality materials, such as aluminum alloys and high-strength steel, are sourced, and a high degree of technical expertise is required to assemble the machines correctly. As part of the manufacturing process, components undergo rigorous testing to comply with international standards, such as ASTM and ISO regulations, before they are assembled.

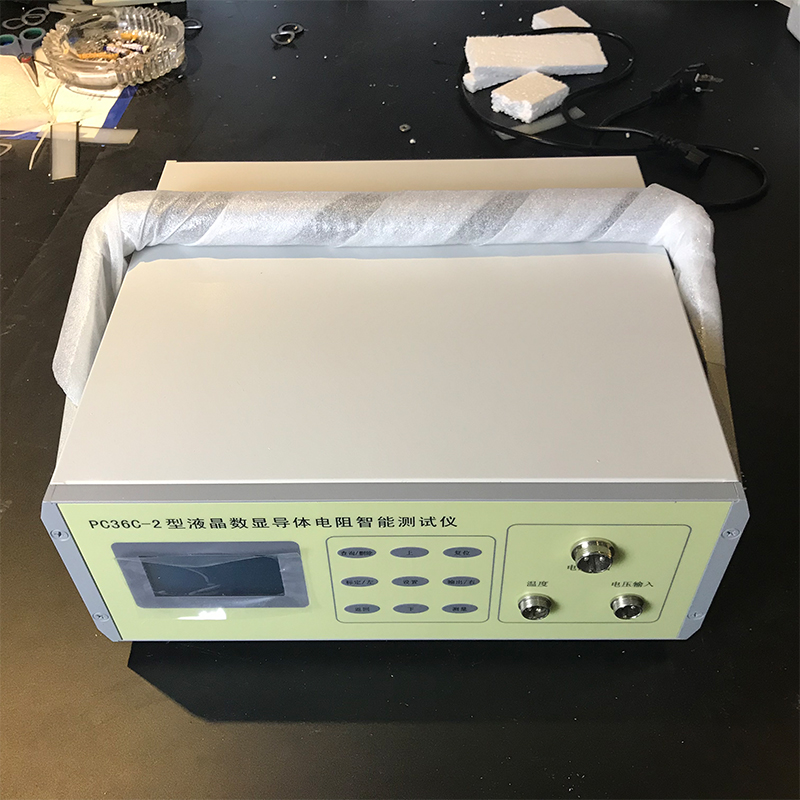

electronic universal tensile testing machine factories

Quality control is a critical component in the production of electronic universal tensile testing machines. Factories implement strict quality assurance protocols at each stage of the manufacturing process. This includes visual inspections, material testing, and routine checks on the machinery’s electronic systems. Many manufacturers also conduct thorough performance evaluations on the finished units, simulating various testing scenarios to ensure the machines operate accurately and reliably under different conditions.

Additionally, many EUTTM factories have embraced the digital revolution. The integration of IoT technology allows for real-time monitoring of machine performance, which can significantly enhance user experience. Advanced data analytics capabilities enable operators to collect and analyze test data instantly, facilitating quicker decision-making. This evolution not only streamlines operations but also provides manufacturers with valuable insights into how their machines perform in actual testing environments.

Furthermore, the global market for electronic universal tensile testing machines is continually expanding. With the increasing emphasis on quality and safety across various industries—such as aerospace, automotive, and construction—demand is on the rise. Factories are now considering the implementation of sustainable practices in their production processes, focusing on reducing waste and energy consumption. This shift towards sustainability resonates well with consumer preferences and regulatory mandates.

In conclusion, the factories that produce electronic universal tensile testing machines are at the forefront of engineering innovation, driven by the necessity for rigorous material testing across numerous industries. Through advanced technology, stringent quality controls, and a commitment to sustainability, these manufacturers ensure that their testing machines meet the evolving demands of the market. As industries continue to prioritize quality, safety, and efficiency, the role of EUTTMs—and the factories that produce them—will only grow in significance, cementing their status as crucial players in advancing material science and engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy