Leading Manufacturer of Electronic Universal Testing Machines for Accurate Material Analysis

The Rise of Electronic Universal Testing Machines in Modern Industries

In today's rapidly advancing technological landscape, the demand for precision and accuracy in material testing has never been greater. This increasing need has driven the development of sophisticated apparatuses known as Electronic Universal Testing Machines (EUTMs). These machines play a pivotal role in quality control, research and development, and material analysis across various industries, including construction, automotive, aerospace, and manufacturing.

Understanding Electronic Universal Testing Machines

Electronic Universal Testing Machines are versatile instruments designed to evaluate the mechanical properties of various materials. These properties include tensile strength, compressive strength, elongation, and modulus of elasticity, among others. The machines operate through an electronic control system that allows for precise measurement, making them an essential tool for engineers and materials scientists.

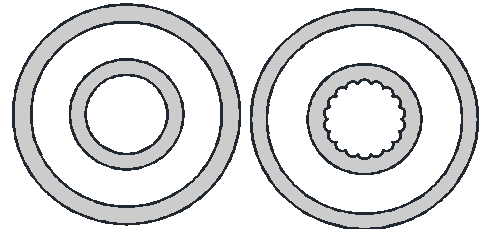

The fundamental structure of an EUTM includes a load frame, an actuator, and a control system. The load frame houses the material specimen, which is subjected to controlled forces. The actuator regulates the application of these forces, while the embedded control system calculates and displays real-time data, ensuring accurate assessments of the material's performance.

Advantages of Electronic Universal Testing Machines

One of the significant advantages of EUTMs is their high level of precision and automation. Unlike traditional testing machines that rely on mechanical gauges and manual calculations, EUTMs utilize digital sensors and automated data logging. This reduces human error and enhances the repeatability of tests. Additionally, the electronic controls enable users to set specific test parameters, such as speed, load, and displacement, which can lead to more consistent and reliable results.

Another notable benefit is the ability to perform a wide variety of tests with a single machine. EUTMs can be configured to conduct tensile, compression, bending, and cyclic loading tests, making them adaptable to different materials and applications. This versatility is particularly valuable for industries that require extensive material testing as part of their R&D processes.

Applications Across Industries

electronic universal testing machine company

EUTMs are increasingly essential in numerous sectors. In the automotive industry, for instance, they are employed to test the durability and safety of components like tires, seat belts, and chassis materials. This testing ensures that vehicles meet stringent safety standards and perform reliably under various conditions.

In the aerospace sector, where material integrity is critical due to the high-stakes environment, EUTMs facilitate the rigorous testing of lightweight composites and alloys used in aircraft construction. Engineers leverage the data from these tests to optimize material selection and design, ultimately enhancing the safety and performance of aircraft.

The construction industry also extensively utilizes EUTMs for testing building materials, such as concrete and steel. By assessing the strength and elasticity of these materials, engineers can ensure compliance with safety regulations and durability requirements, laying the foundation for resilient infrastructure.

Future Trends

As technology continues to evolve, the future of Electronic Universal Testing Machines looks promising. Advancements in artificial intelligence (AI) and machine learning are expected to enhance the capabilities of these machines. For instance, AI algorithms could analyze testing data to predict material performance under various conditions, significantly streamlining the R&D process.

Furthermore, the integration of IoT (Internet of Things) technology may allow EUTMs to share real-time data with other devices or software platforms. This connectivity can facilitate remote monitoring, predictive maintenance, and automated reporting, further optimizing workflow and enhancing productivity.

Conclusion

In conclusion, Electronic Universal Testing Machines represent a critical component in the realm of material testing and analysis. Their precision, versatility, and automation make them indispensable across a wide range of industries. As technology continues to advance, the role of EUTMs is set to expand further, ushering in a new era of material science and engineering. By investing in these advanced testing solutions, industries can ensure they remain competitive and capable of meeting the challenges of the future.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy