Evaluation of Smoke Density in Cable Test Chambers for Enhanced Safety Standards and Performance Measures

Cable Smoke Density Test Chamber Ensuring Safety Through Standards

In the realm of electrical safety and fire prevention, the importance of assessing the smoke density produced by cables can never be understated. Cables, often concealed in walls and ceilings, can pose significant hazards if they catch fire. The cable smoke density test chamber is a crucial tool in evaluating the combustion properties of various cable materials, ensuring that they meet safety standards and regulations.

What is a Cable Smoke Density Test Chamber?

A cable smoke density test chamber is a controlled environment designed to evaluate the amount and density of smoke produced when cables are subjected to high temperatures or flames. The primary purpose of this testing is to determine how much smoke a cable emits during combustion, which is critical for assessing the potential hazards it could pose in a fire scenario. Smoke density is a vital parameter because it directly affects visibility and respiratory safety during a fire, making it a critical consideration in building design and materials selection.

The Importance of Smoke Density Testing

The smoke produced by burning cables can be highly toxic and can impair visibility, making evacuation difficult in emergencies. The testing conducted in the smoke density test chamber helps to identify cables that produce excessive smoke or toxic gases when burned. It establishes a standardized methodology for evaluating materials, allowing manufacturers to certify their products meet national and international safety standards.

In many jurisdictions, regulations require that electrical cables used in public buildings, such as schools, hospitals, and office complexes, undergo rigorous testing to ensure they do not contribute to fire hazards

. The results from smoke density tests can influence product design, materials used, and ultimately, the safety of a building’s occupants.How Does the Testing Process Work?

cable smoke density test chamber

The testing procedure usually involves placing a sample of the cable into the chamber and subjecting it to an ignition source. The chamber is equipped with sensors and cameras to monitor and analyze the density of the smoke produced during combustion. Various parameters, such as time to ignition, peak optical density, and total smoke release, are measured to give a comprehensive overview of the cable's performance.

The data collected helps to generate specific metrics that can be compared against the established standards. These metrics will dictate whether the cable is approved for use or if modifications are needed to enhance its safety profile.

Advancements in Smoke Density Testing Technology

Advancements in technology have led to the development of more sophisticated smoke density test chambers that provide more accurate results. Modern chambers often have improved sensitivity, allowing for the detection of even low levels of smoke production. Additionally, advancements in software enable better data analysis and visualization, making it easier for manufacturers and regulators to interpret results.

Moreover, with the push toward sustainable materials in various industries, testing chambers must adapt to evaluate new types of cables made from alternative materials effectively. This capability is essential as the market evolves and the demand for environmentally friendly yet fire-safe products rises.

Conclusion

In conclusion, the cable smoke density test chamber plays an integral role in ensuring the safety of electrical installations by evaluating the combustion properties of cables. As building codes and safety regulations continue to evolve, the importance of such testing will only grow. By investing in research and adhering to rigorous testing standards, manufacturers can make significant strides in enhancing the safety and performance of their cable products. Ultimately, this leads to better protection for the occupants of any building, minimizing risks in the event of a fire.

-

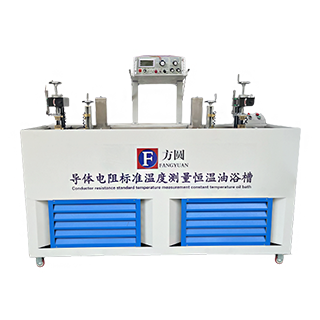

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy