Exporter of Advanced Conductor Resistance Testing Equipment for Reliable Electrical Performance Evaluation

Understanding the Importance of Conductor Resistance Test Machines for Export

In the world of electrical engineering and manufacturing, ensuring the reliability and safety of electrical components is paramount. One critical aspect of this assurance lies in the evaluation of conductor resistance. Conductor resistance test machines play an essential role in this process, particularly for exporters of electrical products. This article delves into the significance, features, and advantages of these testing machines in the export sector.

What is Conductor Resistance Testing?

Conductor resistance testing is the process of measuring the resistance of electrical conductors, such as wires and cables. High operational efficiency is essential for electrical systems, and excessive resistance can lead to overheating, energy losses, and potential system failures. Regular testing of conductor resistance is vital for maintaining compliance with industry standards and ensuring the integrity of electrical installations.

For manufacturers and exporters, demonstrating compliance with international standards is crucial, as it affects their marketability and reputation. Therefore, using a reliable conductor resistance test machine becomes indispensable for quality control.

Features of Conductor Resistance Test Machines

Modern conductor resistance test machines come with various features designed to increase efficiency and accuracy

1. High Precision Measurement These machines utilize advanced technology to provide accurate readings of resistance, which are essential for meeting regulatory requirements and customer expectations. 2. User-Friendly Interface Many devices are equipped with intuitive software that simplifies the testing process and allows users to easily interpret results.

3. Data Storage and Connectivity Test machines often come with data logging capabilities, allowing for the storage of test results for future reference. Connectivity options, like USB and Bluetooth, enable easy export of data to computers and mobile devices for analysis.

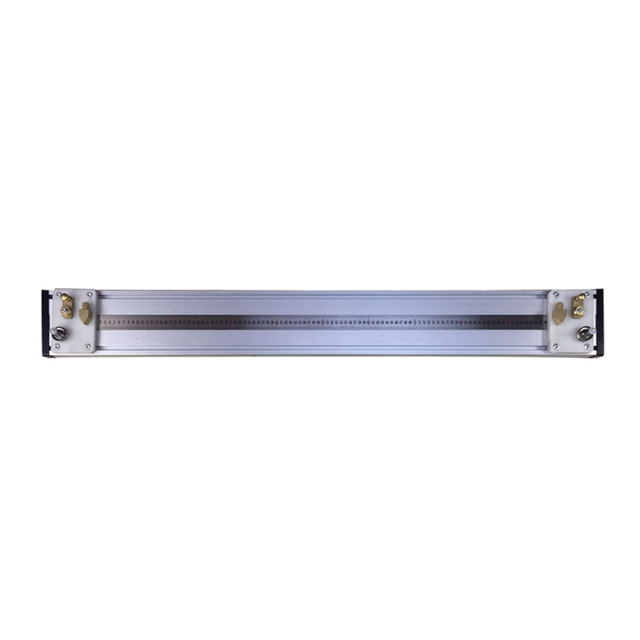

conductor resistance test machine exporter

5. Wide Testing Range Many machines can test a broad spectrum of conductor sizes and types, making them versatile tools for different manufacturing contexts.

Advantages for Exporters

For companies engaged in exporting electrical products, conductor resistance test machines offer several advantages

1. Compliance with International Standards Exporters must adhere to the specific standards of the countries they are selling to. Conducting resistance tests ensures their products meet these requirements, thereby facilitating smoother entry into foreign markets.

2. Enhanced Product Reliability By ensuring that conductors have optimal resistance levels, exporters can reduce the risk of product failures, which can lead to costly recalls and damage to reputation.

3. Improved Customer Confidence Providing verified data on conductor resistance speaks volumes to potential buyers. It demonstrates a commitment to quality and reliability, which can lead to increased sales and customer loyalty.

4. Cost-Effectiveness Regular testing can help identify issues early, allowing manufacturers to address problems before they escalate into more significant and costly repairs or redesigns.

5. Streamlined Operations The use of advanced testing machines can cut down on labor costs and time associated with manual testing methods, leading to a more streamlined production process.

Conclusion

In conclusion, conductor resistance test machines are essential for manufacturers and exporters within the electrical engineering sector. They ensure product quality, compliance with international standards, and bolster customer trust. As the global market continues to evolve, investing in advanced testing technologies can provide significant competitive advantages for exporters. As the demand for reliable electrical components grows, so too does the role of these testing machines in facilitating safe and effective electrical solutions worldwide.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy