fabric tensile strength tester exporters

Understanding Fabric Tensile Strength Tester Exporters

The textile industry is one of the most vital sectors contributing to the global economy. Within this industry, the importance of fabric testing cannot be overstated, particularly when it comes to tensile strength. Fabric tensile strength testers are essential tools that measure the force required to pull fabric apart, providing critical data on the material's durability and performance under stress. As international trade flourishes, exporters of fabric tensile strength testers play a crucial role in ensuring that manufacturers worldwide have the equipment needed to maintain quality standards.

The Importance of Fabric Tensile Strength Testing

Tensile strength testing of fabrics is a fundamental process in quality control for textile manufacturers. The tensile strength of a fabric affects its end-use applications; for example, fabrics used in outdoor gear or automotive materials must endure greater stress and strains compared to those used in casual clothing. Manufacturers rely on tensile testing to ensure that their fabrics meet industry standards and can withstand the rigors of their intended applications.

Testing provides valuable insight into a fabric's properties such as elasticity, durability, and resistance to wear. The results can influence product design, material selection, and pricing strategies, ultimately contributing to consumer satisfaction and safety.

The Role of Exporters in the Testing Equipment Market

Exporters of fabric tensile strength testers are critical players in the global textile equipment market. They bridge manufacturers in developing countries with advanced testing technology that may not be readily available domestically. By providing access to state-of-the-art testing equipment, these exporters help garment manufacturers enhance their product quality, comply with international standards, and remain competitive in the global market.

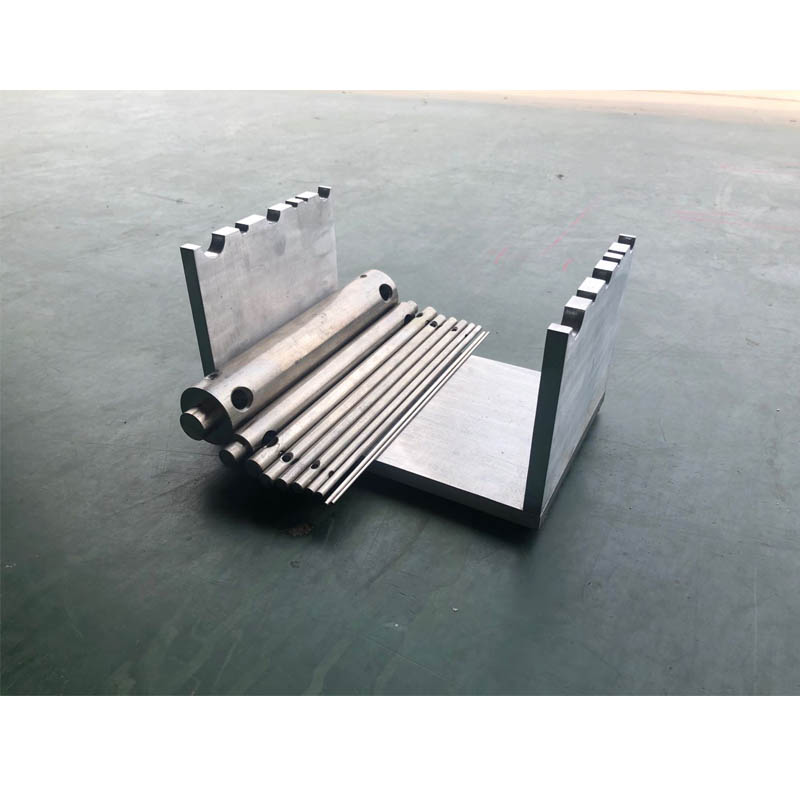

The demand for high-quality fabric tensile strength testers has surged in recent years, driven by the increasing emphasis on quality assurance in the textile industry. Exporters typically offer a range of testing machines that cater to different needs, including electronic tensile testers, universal testing machines, and specialized equipment designed for specific types of fabrics.

Key Features of Quality Fabric Tensile Strength Testers

fabric tensile strength tester exporters

When sourcing fabric tensile strength testers, manufacturers should consider several key features to ensure they are investing in equipment that meets their requirements

1. Accuracy and Precision The ability of the tester to deliver precise measurements is crucial. Accurate data allows manufacturers to make informed decisions about their materials.

2. User-Friendly Interface An intuitive control panel and software can enhance the usability of the device, allowing operators to perform tests efficiently.

3. Versatility Testers that can accommodate various fabric types – from woven textiles to knits and nonwovens – provide greater value to manufacturers.

4. Durability and Maintenance High-quality testers made from robust materials are essential, as they will endure wear and tear over time. Regular maintenance and support from the exporter are also vital.

5. Compliance with Standards Quality testers confirm compliance with international testing standards like ASTM and ISO, which is crucial for global market access.

Conclusion

As the textile industry continues to evolve, the role of fabric tensile strength tester exporters will be increasingly significant. These exporters not only supply essential testing equipment but also help manufacturers enhance their production processes and meet the demands of the global market. By understanding the importance of tensile strength testing and the essential features to look for in testing equipment, manufacturers can ensure they are equipped to produce high-quality fabrics that meet customer expectations and regulatory standards. In this competitive landscape, leveraging advanced testing technology is crucial for sustained success in the textile industry.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy