Fire Resistance Test Equipment Manufacturer for Safety Standards Compliance

Understanding Fire Resistance Test Machines A Look into Their Role and Manufacturing

In an era where safety standards are paramount, the importance of fire resistance testing cannot be overstated. This is where fire resistance test machines come into play, serving as pivotal tools in assessing the fire performance of various materials and structures. Manufacturers of these machines have a crucial role in the construction and materials industry, ensuring compliance with safety regulations and providing reliable results.

Fire resistance test machines are designed to simulate extreme fire conditions, allowing researchers and engineers to evaluate how materials withstand heat, flame, and smoke. The results derived from these tests are critical in determining the suitability of materials for use in buildings, vehicles, and various other applications where fire risk is a concern. In essence, these machines help to protect life and property by ensuring that only materials that meet rigorous fire safety standards are used in construction.

Features of Fire Resistance Test Machines

Manufacturers of fire resistance test machines focus on several key features to ensure their equipment is efficient, accurate, and versatile

1. Temperature Control A major aspect of these machines is their ability to maintain consistent and extreme temperatures over specific periods. Advanced systems often use PID controllers, which allow for precise temperature regulation to mimic real-life fire scenarios.

2. Data Acquisition Systems Modern test machines are equipped with sophisticated data acquisition systems that record temperature changes, material performance, and other variables during the testing process. This data is essential for analysis and can be used to improve materials and testing processes.

3. Safety Protocols Given the inherent risks involved in fire testing, manufacturers incorporate robust safety features. These may include automated shutdown mechanisms, fire suppression systems, and protective enclosures to ensure the safety of operators.

4. Compliance with Standards Fire resistance test machines must adhere to various national and international testing standards, such as ASTM, ISO, and UL. Manufacturers must ensure their machines can conduct tests that meet these regulatory requirements, providing clients with a guarantee of reliability and accuracy.

fire resistance test machine factory

The Manufacturing Process

The manufacturing of fire resistance test machines is a complex process that involves meticulous planning, engineering, and testing. Typically, it starts with the design phase, where engineers create blueprints that consider functionality, durability, and compliance with safety standards.

Once the designs are finalized, the manufacturing process involves the fabrication of components using high-quality materials that can withstand extreme temperatures and stress. Each component is then assembled, often requiring precision work to ensure that all parts function harmoniously.

After assembly, rigorous testing is conducted on the machines themselves to confirm their performance and reliability. Manufacturers often run a series of fire resistance tests to simulate real-world conditions before the machines are delivered to clients.

Conclusion

Fire resistance test machines play a crucial role in enhancing safety standards across various industries. By evaluating the fire performance of materials, these machines help ensure that only the safest products are used in construction and manufacturing. The process of manufacturing these complex machines involves cutting-edge technology and strict adherence to safety and regulatory standards.

As industries evolve and the demand for fire-resistant materials increases, the importance of fire resistance test machines and their manufacturers will only grow. Their contributions not only protect lives but also play a vital role in advancing material science and fire safety technology. In a world where safety is increasingly critical, fire resistance test machines are indispensable tools that help us navigate the risks associated with fire hazards.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

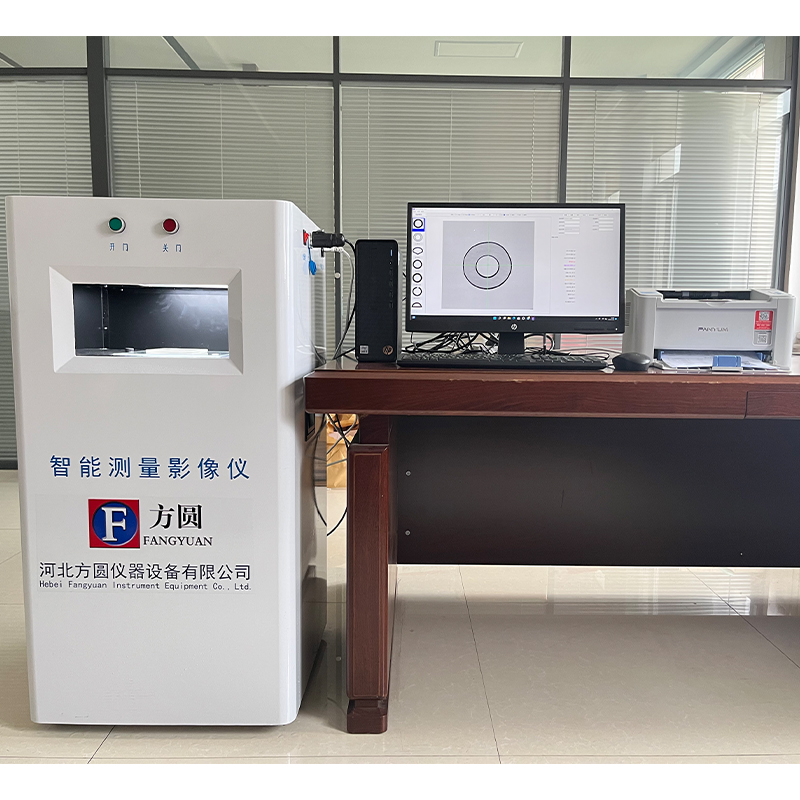

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy