flat cable cutter factories

Flat Cable Cutter Factories An Overview of Design and Manufacturing

In the modern age of technology, flat cable cutters have become indispensable tools in various industries, including telecommunications, electronics, and automotive. The design and manufacture of these tools are primarily carried out in specialized factories, which are crucial for ensuring quality, efficiency, and innovation in production.

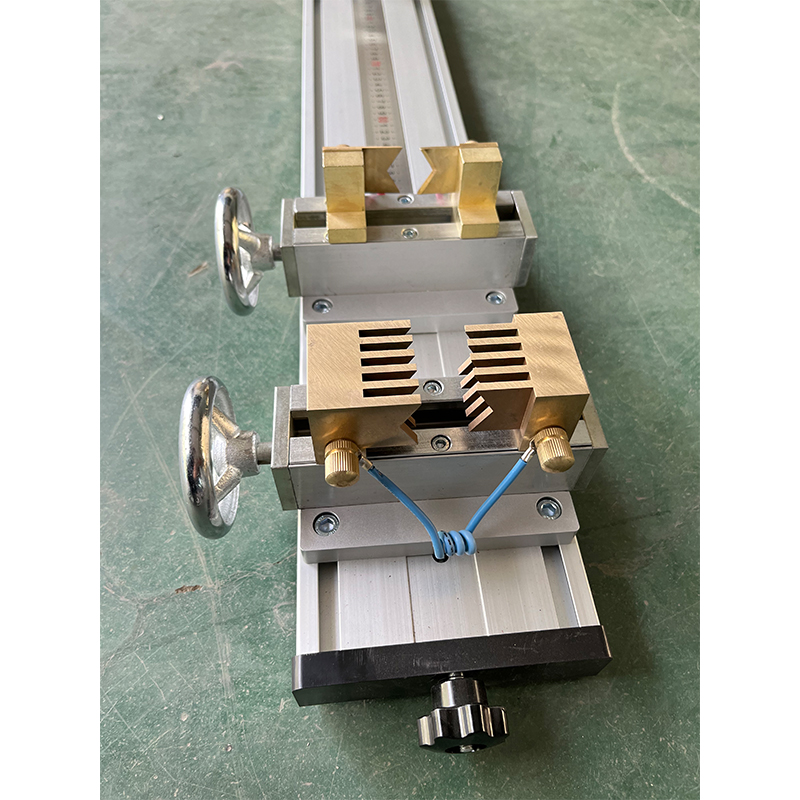

Flat cable cutters are designed specifically to handle the unique characteristics of flat cables, which are widely used due to their flexibility and space-saving designs. These cables often have multiple conductors within a single flat configuration, making them ideal for applications where space is at a premium. However, cutting these cables requires precise tools to avoid damaging the conductors within, which highlights the importance of specialized factories dedicated to the production of cable cutting tools.

The manufacturing process in flat cable cutter factories involves several critical stages, starting with the selection of high-quality materials. Manufacturers typically use hardened steel or alloy materials designed to withstand the wear and tear of regular use. The choice of material significantly impacts the longevity and reliability of the cutting tool.

Once materials are selected, the next step involves precision machining. Advanced CNC (Computer Numerical Control) machines are commonly utilized to cut, shape, and finish the components of the flat cable cutters. This process ensures that each tool meets strict dimensional tolerances, allowing for smooth and efficient cutting action. Additionally, factories utilize laser cutting technology for intricate designs that require high precision, enhancing the overall performance of the cable cutters.

flat cable cutter factories

Quality control is another critical component of flat cable cutter factories. Each batch of products undergoes rigorous testing to ensure they can meet the industry standards and customer expectations. This testing includes evaluating the sharpness of the cutting edges, the stability of the hinges, and the overall ergonomics of the tool. Proper quality assurance processes help prevent defects and ensure customer satisfaction, which is crucial for maintaining a competitive edge in the market.

Moreover, innovation plays a vital role in the competitiveness of flat cable cutter factories. Many manufacturers invest in research and development to create ergonomic designs that maximize comfort and reduce fatigue during use. Features such as non-slip grips and lightweight materials are increasingly common in new models, aiming to enhance user experience.

Sustainability is also becoming a significant focus within these factories. Many manufacturers are adopting eco-friendly practices, such as reducing waste during the production process and utilizing recyclable materials for packaging.

In conclusion, flat cable cutter factories are fundamental to producing high-quality cutting tools that meet the needs of various industries. Through careful material selection, precision manufacturing, rigorous quality control, innovation, and sustainability initiatives, these factories continue to contribute significantly to technology and engineering advancements. As industries evolve, the importance of reliable and efficient cutting tools will undoubtedly persist, driving further developments within flat cable cutter manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy