Flexible Cables Testing Equipment

Understanding Flexible Cables Testing Equipment Ensuring Safety and Reliability

In our increasingly electrified world, the reliable functioning of flexible cables is paramount. These cables, which are designed for versatility and adaptability in a range of applications, require rigorous testing to ensure they meet safety and performance standards. This is where flexible cables testing equipment comes into play.

Flexible cables are commonly used in various settings, from construction sites to manufacturing plants, and even in residential areas. Due to their frequent movement and bending, these cables are subject to unique stresses that can compromise their integrity over time. Therefore, testing equipment tailored for flexible cables is essential for determining their durability and performance under real-world conditions.

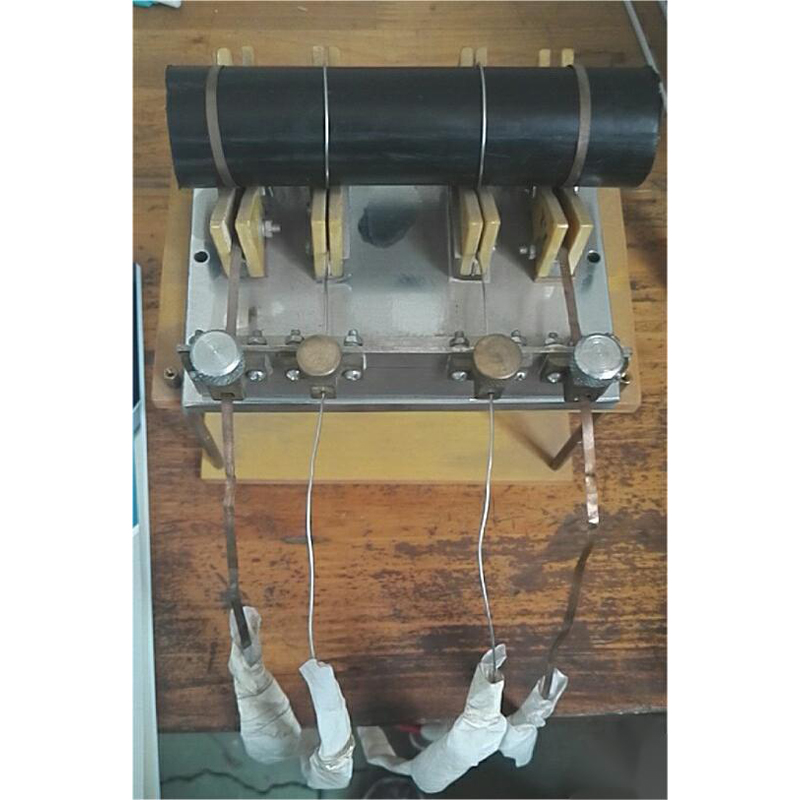

The key component of flexible cables testing equipment is its ability to simulate the conditions that cables will face in practical applications. This includes bending, twisting, and stretching, which are critical factors that can affect a cable's lifespan and functionality. By using specialized machines that can replicate these stresses, manufacturers and safety inspectors can evaluate how well a cable can withstand these physical demands.

One of the primary tests conducted using flexible cables testing equipment is the bend test. This involves repeatedly bending the cable at specified angles and frequencies to determine at what point it may fail or show signs of wear. Additionally, the tensile strength test assesses how much pulling force a cable can endure before breaking, which is particularly important for cables used in high-stress environments.

flexible cables testing equipment

Moreover, insulation resistance testing is vital for ensuring that flexible cables maintain their protective qualities. This test measures the effectiveness of the cable's insulation in preventing electrical leaks, which can lead to short circuits and potential hazards. A reliable testing setup will ensure that these parameters are accurately measured and reported.

Another critical aspect of flexible cables testing equipment is its ability to provide real-time data and analytics. Modern testing devices are often equipped with advanced technology that allows for immediate feedback, helping manufacturers make informed decisions quickly. This capability not only enhances quality control but also aids in regulatory compliance, as many industries are governed by strict safety standards.

Furthermore, the portability and versatility of flexible cables testing equipment are important features that enhance its usability. Many of these devices are designed to be compact and lightweight, allowing for testing in various locations, whether on-site or in a laboratory setting. This flexibility is crucial for industries that require frequent testing of multiple cables or those working in remote areas.

In conclusion, the role of flexible cables testing equipment is indispensable in ensuring the safety and reliability of flexible cables. As technology continues to advance, so too will the methods and tools used in testing, leading to improved standards in the industry. By investing in robust testing solutions, manufacturers not only enhance the longevity of their products but also protect consumers and industries that depend on safe and reliable electrical connections.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy