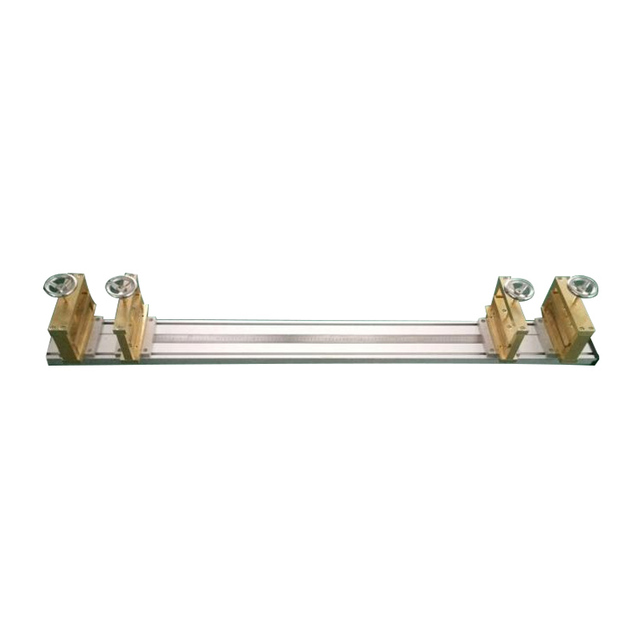

flexible cable flexing test equipment

Understanding Flexible Cable Flexing Test Equipment

When it comes to the reliability and durability of electrical systems, the performance of flexible cables is paramount. These cables are designed to withstand dynamic movements and repeated bending, which is why testing their flexibility and resistance to fatigue is essential. In today's article, we will delve into the significance of flexible cable flexing test equipment and the various testing methodologies it employs.

The Importance of Flexible Cables

Flexible cables are widely used in numerous applications, including robotics, automotive systems, industrial machines, and consumer electronics. Their ability to bend and flex without compromising functionality makes them an excellent choice for environments where movement is frequent. However, over time, continual flexing can lead to wear and tear, resulting in electrical failures or cable breakage. This potential for failure means that manufacturers and engineers must invest in robust testing to ensure these cables can endure their intended applications without significant degradation.

What is Flexible Cable Flexing Test Equipment?

Flexible cable flexing test equipment is specialized machinery designed to analyze the performance of cables under bending and flexing conditions. It simulates the real-world conditions that cables will experience in their operational environments. The primary objective of this equipment is to evaluate the durability, flexibility, and overall structural integrity of cables under various bending parameters, ensuring they meet necessary safety and performance standards.

Key Features of Flexing Test Equipment

1. Bending Radius Control The equipment often allows users to configure the bending radius to mimic the specific flexing conditions that cables will encounter in their applications. This is crucial for understanding how different cables perform under varying scenarios.

2. Cycle Counting A reliable flexible cable flexing tester features cycle counting functionality, allowing technicians to monitor how many cycles the cable has endured before any failure occurs. This data is crucial for determining the expected lifespan of the cable in a real-world application.

3. Automated Testing Advanced test equipment often comes with automation capabilities, enabling continuous testing without manual intervention. This increases efficiency and reduces the potential for human error during testing.

flexible cable flexing test equipment

4. Data Logging and Analysis Modern test equipment includes data logging features that capture performance metrics during the test. This not only aids in compliance with industry standards but also assists engineers in refining cable designs based on empirical data.

5. Ergonomic Design To facilitate ease of use, test equipment is often designed with ergonomics in mind. This ensures that technicians can conduct tests efficiently and comfortably.

Testing Standards and Compliance

Flexible cable testing must adhere to specific industry standards, which can vary based on the application and region. For instance, automotive cables might need to comply with standards set by organizations such as SAE (Society of Automotive Engineers), while general electrical cables might need to follow IEC (International Electrotechnical Commission) guidelines. By using flexible cable flexing test equipment compliant with these standards, manufacturers can ensure that their products meet necessary safety and quality requisites.

Benefits of Conducting Flexing Tests

Conducting flexing tests using appropriate equipment offers several benefits

- Risk Mitigation Identifying potential failures before cables are deployed significantly reduces the risk of malfunction in critical systems. - Enhanced Product Quality Rigorous testing ensures that only high-quality cables reach the market, thereby improving customer satisfaction and brand reputation. - Regulatory Compliance Passing necessary tests aids manufacturers in complying with industry regulations, avoiding legal repercussions and potential recalls.

Conclusion

Flexible cable flexing test equipment is an indispensable asset in the cable manufacturing and testing domain. It not only ensures the longevity and reliability of flexible cables but also fosters innovation in cable design and application. As the demand for flexible cables continues to grow amidst advancements in technology, the importance of robust testing practices cannot be overstated. Manufacturers who invest in high-quality flexing test equipment are not just protecting their products; they are enhancing the safety and reliability of the systems that rely on these vital components.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy