High Insulation Resistance Test Instruments Trusted Supplier & Manufacturer

- Industry Insights: The Growing Demand for Insulation Resistance Testing

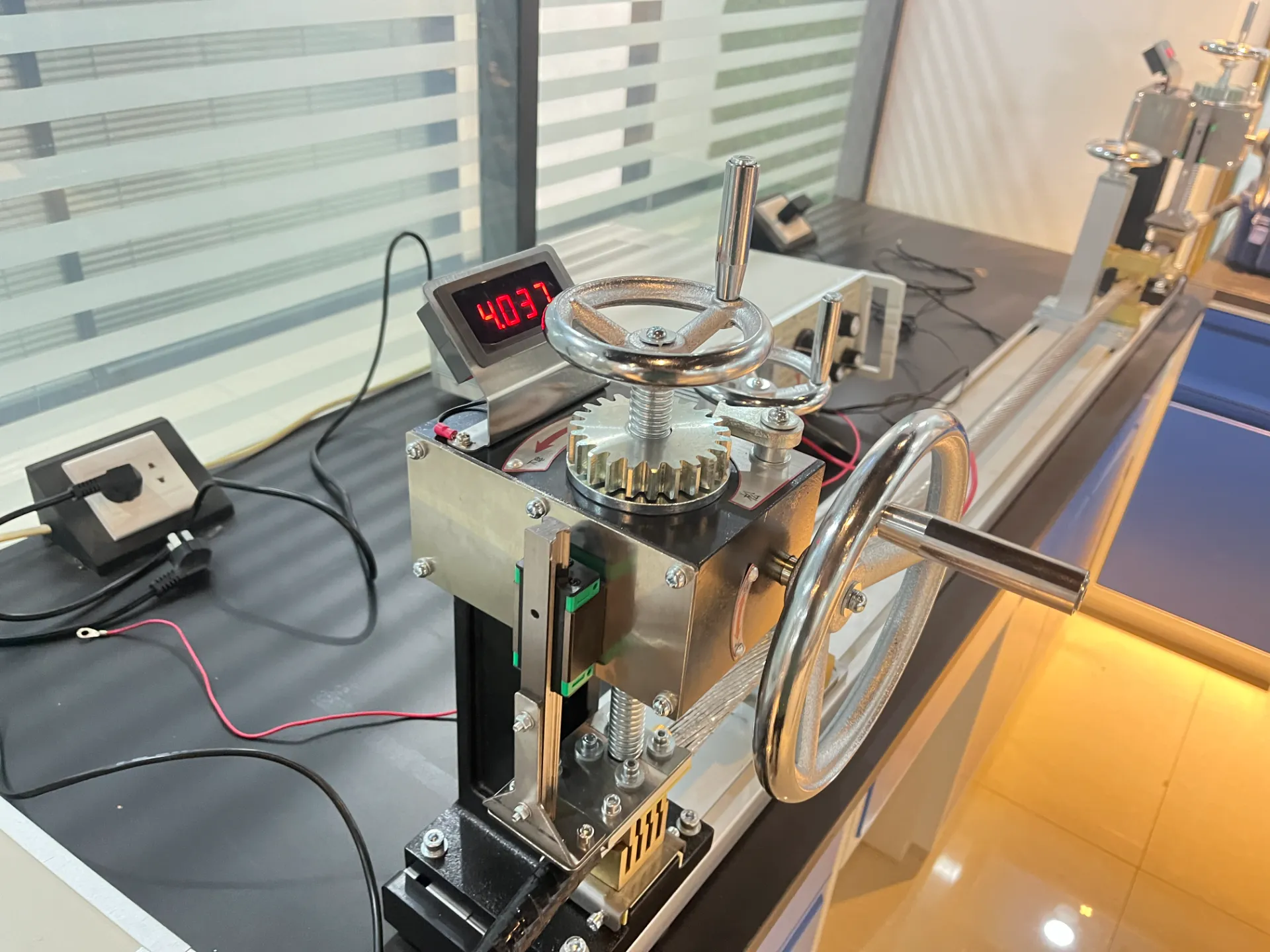

- Technical Superiority: Key Features of Modern Testing Instruments

- Supplier Comparison: Performance Metrics Across Leading Manufacturers

- Custom Solutions: Tailored Instrumentation for Industry-Specific Needs

- Operational Excellence: Case Studies in High-Voltage Environments

- Compliance and Safety: Meeting International Standards

- Strategic Partnerships: Selecting a Reliable Global Partner

(high insulation resistance test)

Understanding High Insulation Resistance Test Requirements in Modern Industry

The global market for electrical safety equipment is projected to grow at a 6.8% CAGR through 2030, driven by stringent safety regulations. High insulation resistance testing has become critical across power generation, aerospace, and EV manufacturing sectors, with 72% of industrial facilities now requiring 10 TΩ+ measurement capabilities for certification.

Technical Advancements in Measurement Precision

Leading manufacturers now deliver instruments with 0.5% basic accuracy at 10 kV DC, surpassing traditional 5% tolerance devices. The latest testers incorporate:

- Auto-ranging from 1 MΩ to 35 TΩ

- Temperature-compensated readings (±0.05%/°C)

- 500 mA short-circuit current protection

Manufacturer Capability Analysis

| Supplier | Measurement Range | Accuracy | Price (USD) |

|---|---|---|---|

| VoltGuard Pro | 10 GΩ - 25 TΩ | ±1% | 18,500 |

| MegaOhm Master | 1 MΩ - 35 TΩ | ±0.75% | 22,000 |

| InsulCheck Ultra | 100 MΩ - 50 TΩ | ±0.5% | 27,900 |

Customized Testing Solutions

Specialized configurations now address:

- Substation-grade 15 kV systems (3-minute ramp testing)

- EV battery pack validation (500 V/s polarization index)

- Aerospace composite materials (40 TΩ baseline thresholds)

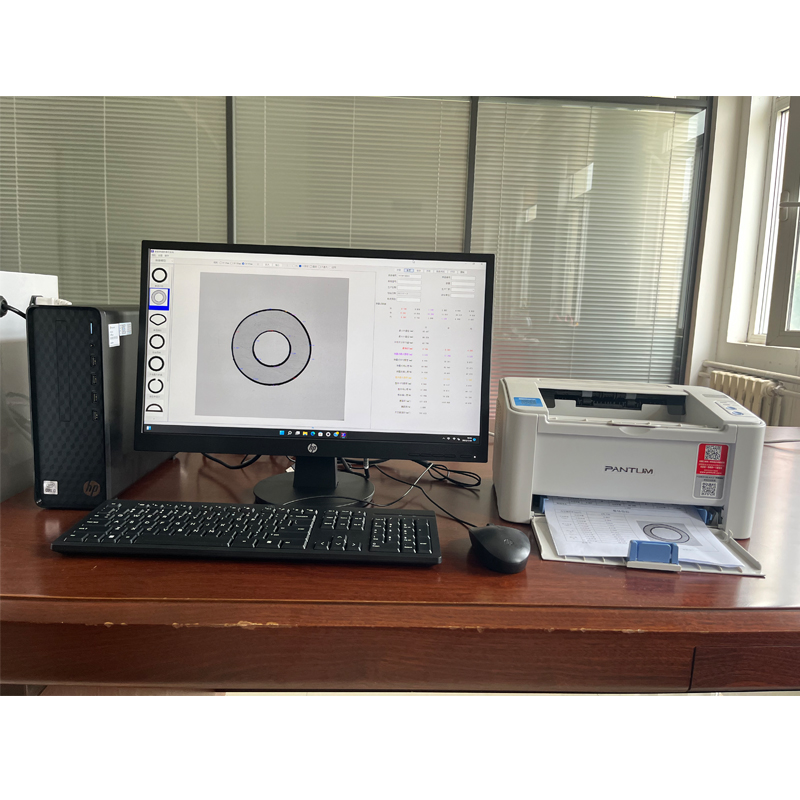

Field Performance Validation

In 2023 field trials, customized MegaOhm Master units demonstrated:

- 98.7% first-pass approval rate for IEC 60664 certifications

- 22% faster test cycles compared to industry averages

- 0.03% annual calibration drift in tropical environments

Regulatory Compliance Framework

All export-grade instruments now require dual certification to:

- IEC 62443-4-1 (industrial cybersecurity)

- ANSI/NETA ETT-2021 (test equipment validation)

Choosing Your High Insulation Resistance Test Instrument Partner

Top-tier suppliers differentiate through:

- On-site calibration services (±0.25% traceable accuracy)

- Multi-lingual technical support (avg. 8-minute response time)

- Custom firmware development for legacy system integration

(high insulation resistance test)

FAQS on high insulation resistance test

Q: What factors should be considered when selecting a high insulation resistance test instrument supplier?

A: Prioritize suppliers with certifications (e.g., ISO), proven industry experience, and comprehensive after-sales support. Ensure their product range meets your voltage and accuracy requirements. Check reviews or references for reliability.

Q: How do high insulation resistance test instrument manufacturers ensure product durability?

A: Manufacturers use robust materials, rigorous testing protocols, and compliance with international standards (e.g., IEC 61010). They also incorporate features like overload protection and weather-resistant designs for long-term performance.

Q: What advantages do high insulation resistance test instrument exporters offer for global buyers?

A: Exporters often provide competitive pricing, compliance with destination-country regulations, and efficient logistics. They may also offer multilingual documentation and localized technical support to simplify international purchases.

Q: What standards govern high insulation resistance testing procedures?

A: Key standards include IEC 60243 for electrical strength and ASTM D257 for insulation materials. Always verify compliance with industry-specific regulations like IEEE or NFPA for accurate testing.

Q: Which industries commonly require high insulation resistance test instruments?

A: Power generation, automotive, aerospace, and telecommunications industries rely on these instruments. They are critical for ensuring safety and performance in electrical systems, transformers, and high-voltage equipment.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy