High Performance Insulation Resistance Testing Equipment for Reliable Electrical Safety Solutions

The Importance of High Insulation Resistance Test Equipment in Electrical Safety

In the realm of electrical engineering and maintenance, the significance of insulation cannot be overemphasized. Insulation serves as a critical barrier, protecting conductors and ensuring the safe operation of electrical systems. High insulation resistance test equipment plays an essential role in evaluating the integrity of insulating materials, detecting potential failures before they become catastrophic. As industries increasingly prioritize safety and efficiency, the demand for reliable test equipment is at an all-time high.

Understanding Insulation Resistance Testing

Insulation resistance testing involves measuring the resistance offered by insulation materials to the flow of electrical current. This testing is crucial for identifying issues such as moisture ingress, deterioration due to aging, or physical damage. The resistance value provides insight into the health of the insulation; higher resistance indicates that the insulation is functioning correctly, while lower values suggest potential faults.

Typically, the testing process involves applying a voltage to the insulation and measuring the resulting current. This data is then used to calculate the insulation resistance value, often expressed in megohms (MΩ). Different industries and applications may have varying standards for acceptable resistance levels, which highlights the need for accurate and dependable testing equipment.

Features of High Quality Insulation Resistance Test Equipment

Modern insulation resistance test equipment comes with a suite of features designed to facilitate accurate and efficient testing

1. Variable Voltage Options Quality test equipment allows testers to set various output voltage levels. Different applications may require different testing voltages; for example, electronics testing often uses lower voltages, while industrial applications may require higher voltages.

2. Data Logging and Storage Advanced models include data logging capabilities, enabling users to record test results over time. This feature is invaluable for trend analysis and ensuring compliance with regulatory standards.

3. User-friendly Interfaces Modern insulation testers often come equipped with intuitive interfaces, making it easier for less experienced technicians to perform tests accurately. Features like color screens, touch controls, and step-by-step guides enhance usability.

4. Automated Testing Features Automation can simplify the testing process, reducing user error. Some devices allow for pre-programmed tests that can run automatically, improving efficiency and consistency.

high insulation resistance test equipment company

5. Durability and Portability Many companies now prioritize rugged designs that can withstand the harsh conditions often found in industrial environments. Lightweight and portable equipment allows technicians to conduct tests in various locations.

Applications Across Industries

High insulation resistance testing is vital across multiple sectors, including

- Manufacturing In factories filled with machinery, ensuring that all electrical components are properly insulated helps prevent dangerous accidents and equipment failures. - Construction Electricians testing new installations use insulation resistance testing to verify that electrical systems meet necessary safety standards before going live.

- Utilities Power generation and distribution companies regularly use these tests to maintain the integrity of their infrastructure, safeguarding public safety and operational reliability.

- Renewable Energy As solar and wind energy systems proliferate, the need for rigorous insulation testing grows. Equipment must withstand environmental exposure, making insulation testing essential for long-term reliability.

Choosing the Right Equipment

Selecting the appropriate insulation resistance test equipment involves considering various factors, including the required voltage range, the specific application, and the necessary features for efficiency and accuracy. Leading manufacturers often provide models tailored to different industrial needs, alongside comprehensive support and training services.

When investing in insulation resistance test equipment, quality should be the primary concern. Reliable manufacturers often adhere to international standards and regulations, ensuring that their devices are safe and effective. Additionally, long-term service agreements and warranties can provide peace of mind, safeguarding your investment.

Conclusion

High insulation resistance test equipment is an indispensable tool in maintaining electrical safety and operational efficiency across industries. By ensuring the integrity of insulation materials, companies protect their employees, equipment, and customers. As the push for safety and reliability continues to grow in importance, investing in quality insulation testing equipment is a prudent decision for any organization involved in electrical systems. Choosing the right equipment not only enhances safety but also contributes to the overall longevity and efficiency of electrical installations.

-

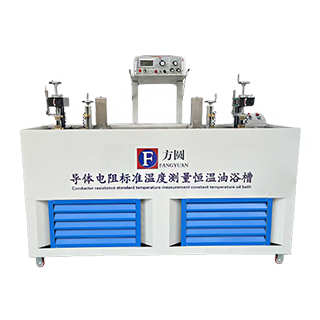

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy