Suppliers of High Insulation Resistance Testing Instruments for Reliable Electrical Measurements

High Insulation Resistance Test Instrument Suppliers Ensuring Safety and Performance

In the world of electrical engineering, safety and reliability are paramount. One of the essential practices in ensuring the safety of electrical systems is conducting insulation resistance tests. This process helps identify potential faults in electrical insulation, preventing failures and hazards. As a result, high insulation resistance test instruments have become indispensable tools for electricians and engineers. The suppliers of these instruments play a crucial role in providing high-quality, reliable equipment that meets industry standards.

What is Insulation Resistance Testing?

Insulation resistance testing measures the resistance of electrical insulation materials to leakage currents. A high insulation resistance value indicates that the insulating material is of good quality and capable of preventing unintended current paths that could lead to short circuits or electrical shocks. Typically, insulation resistance testers apply a high voltage to the insulating material and measure the resulting current flow. This measurement is usually expressed in megaohms (MΩ).

Importance of High Insulation Resistance Test Instruments

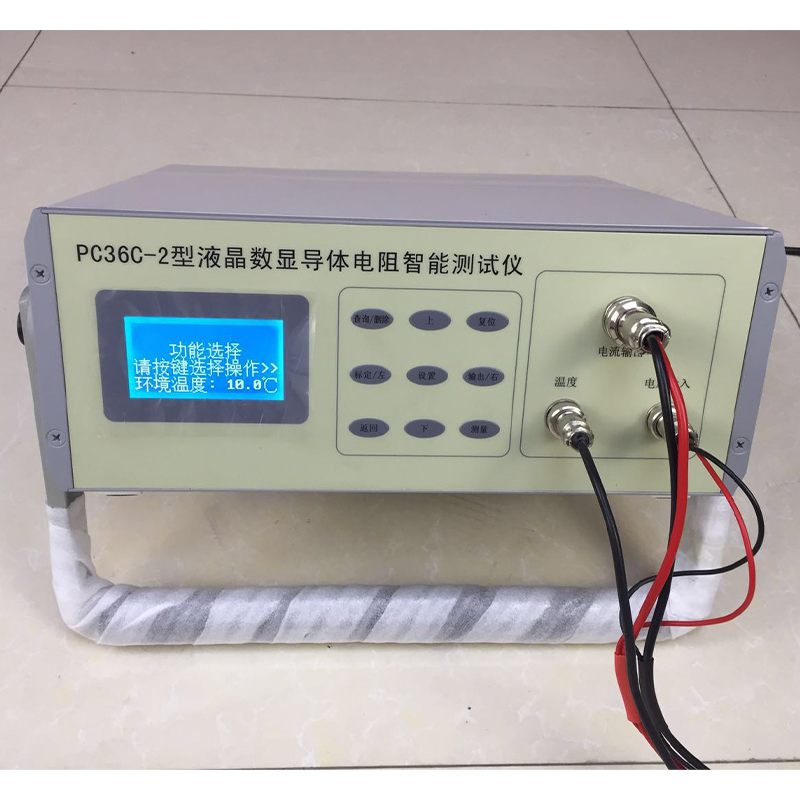

High insulation resistance test instruments come in various forms, including handheld testers, benchtop units, and advanced systems equipped with digital displays, data logging features, and even connectivity options for integration with software solutions. The importance of these instruments cannot be understated

1. Safety Regular insulation tests help to identify weaknesses in electrical systems, preventing hazards that could lead to electric shocks or fire hazards. 2. Maintenance Insulation resistance testing is crucial in predictive maintenance strategies for electrical equipment. By identifying potential failures early, organizations can schedule maintenance and avoid costly downtime.

3. Regulatory Compliance Many industries are required to comply with safety regulations that mandate regular insulation testing. High-quality test instruments from reputable suppliers help ensure that these requirements are met.

4. Quality Assurance For manufacturers, the integrity of electrical components is vital. High insulation resistance test instruments help verify that products meet necessary quality and safety standards before they reach the market.

high insulation resistance test instrument suppliers

Choosing a Reliable Supplier

When looking for high insulation resistance test instrument suppliers, several factors should be considered

1. Product Range A reliable supplier should offer a wide range of insulation resistance testers to cater to various applications, from low voltage to high voltage testing.

2. Quality and Certification It is essential that the instruments meet international standards such as IEC, ISO, or ASTM. Suppliers that provide certified equipment ensure that their products have been rigorously tested for quality and performance.

3. Technical Support A reputable supplier will provide comprehensive technical support, including product training, troubleshooting assistance, and after-sales service.

4. Customer Reviews Feedback from customers who have previously purchased from a supplier can provide insights into the quality and reliability of their products and services. Look for suppliers with positive reviews and a strong reputation in the industry.

5. Innovation The electrical industry is constantly evolving, and so are the technologies used. Suppliers that invest in research and development to offer innovative features, such as Bluetooth connectivity and advanced data analysis capabilities, can provide added value.

Conclusion

High insulation resistance test instruments are essential for ensuring the safety, reliability, and performance of electrical systems. By sourcing these instruments from reputable suppliers, engineers and electricians can safeguard their work environments, comply with regulatory standards, and maintain the integrity of electrical installations. As the demand for safety in electrical systems continues to rise, the role of reliable suppliers in providing top-quality testing equipment will become even more critical. Investing in quality insulation resistance testing instruments is not just a matter of compliance; it is an investment in safety and efficiency in electrical operations.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy