homemade tensile strength tester exporters

Homemade Tensile Strength Tester A Practical Solution for Material Testing

The demand for reliable materials testing has surged in various industries, including construction, manufacturing, and research. Understanding the tensile strength – the maximum amount of tensile stress that a material can withstand while being stretched or pulled before failing – is crucial for ensuring safety and performance. Traditionally, tensile strength testing is performed using expensive and complex testing machines. However, with a bit of ingenuity and the right materials, creating a homemade tensile strength tester has become a viable option for laboratories, educational institutions, and enthusiasts alike.

Importance of Tensile Strength Testing

Tensile strength testing serves as a critical quality control measure. It helps engineers and researchers determine how a material will behave under tension, which is essential for applications ranging from structural components to consumer products. Materials like metals, plastics, and composites need to be evaluated to ensure that they meet specified standards and are capable of performing effectively under load. The implications of failing to adequately test materials can lead to catastrophic failures, safety hazards, and financial losses.

DIY Approach to Building a Tensile Strength Tester

Building a homemade tensile strength tester does not require advanced engineering skills. A basic understanding of mechanics and access to common materials can suffice. Here’s a simple guide to creating your own tester.

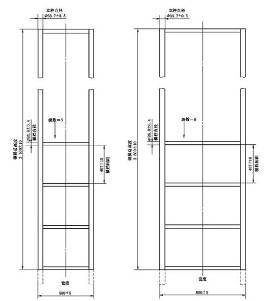

Materials Needed 1. Frame Use sturdy materials like wood or metal to construct the frame that will hold the test specimen. 2. Load Cell A load cell is necessary to measure the force applied to the specimen. These sensors are relatively affordable and can often be found online. 3. Arduino or Microcontroller This will help in reading the data from the load cell and displaying it. Programming the microcontroller will allow for real-time data analysis. 4. Rope or Chain Use a strong rope or chain to apply the tensile force to the specimen. 5. Grip Jaws These can be made from metal or plastic and should securely hold the material being tested at both ends. 6. Weights Additional weights can be used to incrementally apply force to the specimen.

homemade tensile strength tester exporters

Construction Steps 1. Build the Frame Construct a stable frame that will securely hold the specimen and the load cell. 2. Install the Load Cell Position the load cell at the central part of the frame, ensuring it can accurately measure the force exerted on the test material. 3. Attach Grip Jaws Securely attach the grip jaws to both ends of the frame, making sure they can hold the material firmly during testing. 4. Connect the Electronics Connect the load cell to the microcontroller and configure the software to record the readings. 5. Calibrate the Tester Before performing tests, it’s essential to calibrate the system to ensure accuracy in measurements.

Testing Procedure

Once the apparatus is ready, the testing procedure can begin. The specimen is placed securely in the grip jaws, and a load is gradually applied. Increase the load incrementally, monitoring the data displayed on the microcontroller. Record the maximum load the specimen can withstand before failure. This data can provide valuable insights into the material’s characteristics and help simulate real-world applications.

Export Opportunities for Homemade Tensile Strength Testers

With the rise in DIY culture and educational institutions seeking cost-effective solutions for material testing, there’s a burgeoning market for homemade tensile strength testers. Innovators and small businesses can consider exporting their designs, kits, or even fully assembled testers. Regions where educational programs are expanding, or industries involving material analysis are growing, represent significant export opportunities.

Conclusion

Creating a homemade tensile strength tester is not only an exciting project but also a practical solution for conducting essential material tests. With accessible materials and a bit of creativity, individuals and organizations can significantly reduce testing costs while gaining valuable insights into their materials. As the push for efficiency and cost-effectiveness in industries continues, homemade tensile strength testers hold the potential to become a crucial tool across various sectors. By embracing innovation and DIY approaches, we can foster safer and more reliable material usage in our daily lives.

-

Reliable CHJ Series Spark Tester for Insulation Quality Control

NewsSep.01,2025

-

QNJ-2/3 Cable Flexibility Test Machine: Precision & Durability

NewsAug.31,2025

-

DQ-F Superfine Wire Conductor Resistance Fixture: High-Precision Testing

NewsAug.30,2025

-

ZC36 High Insulation Resistance: Reliable & Safe Performance

NewsAug.29,2025

-

CX-100 Manual Hydraulic Core Punching Machine - Efficient & Reliable

NewsAug.28,2025

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy