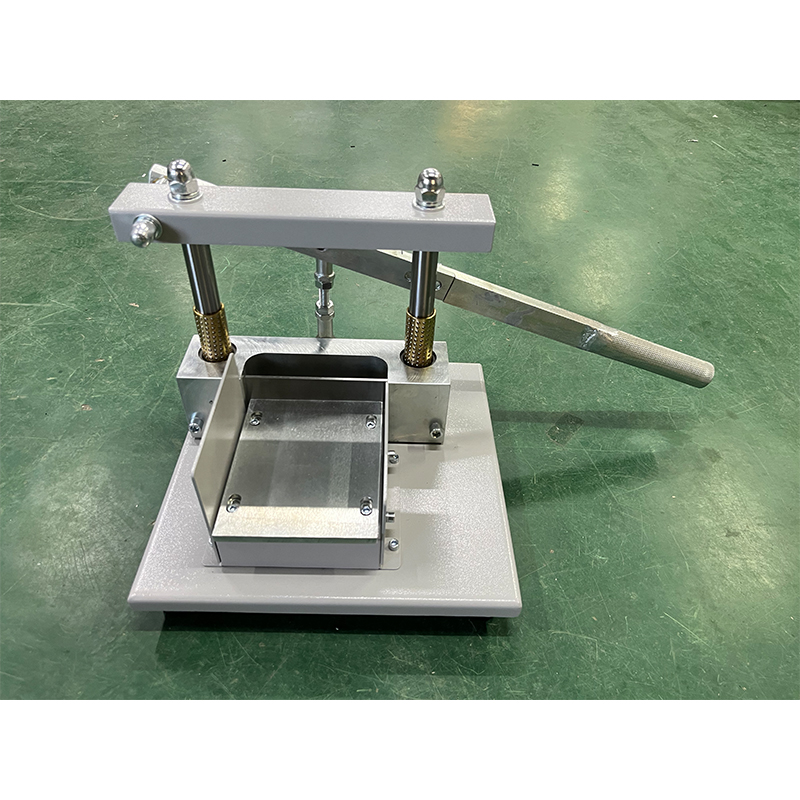

homemade tensile strength tester factory

Building a Homemade Tensile Strength Tester A Do-It-Yourself Guide

Understanding the tensile strength of materials is a critical aspect of engineering and materials science. Tensile strength refers to the maximum amount of tensile (pulling or stretching) stress that a material can withstand before failure. For hobbyists, students, and professionals alike, building a homemade tensile strength tester can be an invaluable project. This article guides you through the process of creating a simple yet effective tensile strength tester from readily available materials.

Materials Required

To build your tensile strength tester, you will need the following materials

1. Frame A sturdy base is essential for stability. You can use metal brackets or wood to construct a frame. 2. Load Cell This device will measure the force exerted on the material you are testing. Choose a load cell with an appropriate weight capacity for your tests. 3. Arduino or Microcontroller To read and display the data from the load cell, an Arduino board can be used. 4. Software You will need software to interface the microcontroller with your load cell. Libraries are available for Arduino that simplify this process. 5. Testing Samples Various materials you wish to test, such as plastic strips, metals, or fibers. 6. Clamps and Fixtures Securely hold your test samples in place during experimentation. 7. Pulling Mechanism This can be a simple winch or geared motor that will apply tension to the sample.

Assembly Instructions

1. Construct the Frame Begin by creating a stable base. Ensure it can withstand the forces during testing. The frame should be tall enough to allow for the stretching of the materials being tested.

2. Install the Load Cell Mount the load cell securely at the center of the frame. This will act as the heart of your testing machine, providing the necessary feedback on the tensile stress experienced by the sample.

3. Connect the Electronics Wire the load cell to the Arduino or microcontroller. Follow the specific wiring diagram provided with your load cell. It typically involves connecting four wires two for power and two for signal.

homemade tensile strength tester factory

4. Programming Once wired, upload a simple program to your Arduino that reads the data from the load cell and outputs the results to a connected display or serial monitor. Numerous online resources and examples can guide you through this process.

5. Create the Pulling Mechanism Attach your pulling mechanism to one end of the load cell. If you're using a motor, ensure it has the capacity to apply sufficient tensile force without burning out.

6. Clamping the Material Attach clamps to your testing samples to hold them securely in place. Ensure the clamps do not weaken the material or interfere with the stress distribution.

Testing Process

1. Calibration Before starting your tests, calibrate the load cell to ensure accurate measurements. Use known weights to calibrate and “zero” the device. 2. Conducting Tests Insert your first test sample and securely clamp it in place. Start applying tension gradually until the material fails. Record the maximum load indicated on the display.

3. Repeat Tests For accuracy, conduct multiple tests with the same type of material to ensure reliable data. Calculate the average tensile strength based on your measurements.

4. Analysis Analyze the data gathered to determine the tensile strength and compare it among different materials.

Conclusion

Building a homemade tensile strength tester is not only an educational project but also an insightful means to understand material properties. This hands-on approach allows you to explore different materials' behaviors and their applications in real-world scenarios. With your homemade tensile strength tester, you can delve deeper into the fascinating world of material science while also enhancing your craftsmanship and technical skills. Happy testing!

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy