DIY Tensile Strength Tester for Home Use and Workshop Applications

Homemade Tensile Strength Tester A DIY Approach to Material Testing

In the world of engineering and material science, understanding the tensile strength of materials is crucial. Tensile strength refers to the maximum amount of tensile (pulling) stress a material can withstand before failure. While commercial tensile strength testers can be expensive and complex, creating a homemade tensile strength tester can be an informative and cost-effective solution that allows enthusiasts, students, and small-scale manufacturers to conduct their own material tests. This article explores the principles, design, and considerations for building a DIY tensile strength tester.

The Importance of Tensile Strength Testing

Tensile strength tests are essential for various applications, from confirming the quality of construction materials to ensuring that products meet safety standards. Engineers utilize this data to select appropriate materials for specific applications, predict how materials will behave under stress, and ensure reliability and longevity in products. Having access to a homemade tensile strength tester can provide valuable insights into the materials you frequently work with, facilitating better project choices and innovations.

Basic Principles of a Tensile Strength Tester

At its core, a tensile strength tester is designed to apply tension to a material sample until it breaks. The key components of a simple design include

1. Frame A sturdy structure is essential to provide stability. Metal or hardwood can serve well, allowing for a fixed support that can handle the forces applied during testing.

2. Load Application Mechanism This could be a simple manual screw or a more sophisticated hydraulic or pneumatic setup. The goal is to apply force systematically to the specimen.

3. Load Measurement Device A scale or load cell can be used to measure the force applied to the sample. This data is crucial for calculating the tensile strength.

4. Specimen Holder Properly holding the sample is critical. This can be achieved through clamps or grips that securely hold the material without inducing premature failure.

homemade tensile strength tester factory

Designing and Building the Tester

When designing your homemade tensile strength tester, keep the following steps in mind

1. Identify Your Materials Decide which materials you want to test. This will determine the specifications of your tester. For example, testing metals may require a sturdier frame compared to testing fabric or plastic.

2. Draft a Design Sketch your setup to visualize how each component will work together. Online resources and schematics can offer inspiration and guidance.

3. Gather Materials Collect the necessary materials and tools. Common components may include bolts, screws, metal brackets, load cells, and any electronic parts needed for measurement.

4. Assembly Assemble your tester according to your design. Ensure all joints are secure and that the mechanism for applying force can operate smoothly.

5. Calibration Before testing actual samples, calibrate your load measurement device. This step is crucial to ensure accuracy, and you may want to use known weights to verify measurements.

Safety Considerations

While conducting tensile tests, safety should be a priority. Make sure to wear appropriate personal protective equipment (PPE), including eye protection, and consider conducting tests in a controlled environment to mitigate risks from flying debris or material snapping.

Conclusion

A homemade tensile strength tester can serve as an educational tool and a practical device for material testing. By investing time and effort into creating this tester, you can gain hands-on experience and a deeper understanding of material properties. This DIY approach not only fosters creativity and problem-solving skills but also empowers individuals to carry out experiments that inform their projects and material choices. Whether you are a student, a hobbyist, or a small business owner, building and using a homemade tensile strength tester can open new avenues for experimentation and innovation in material science.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

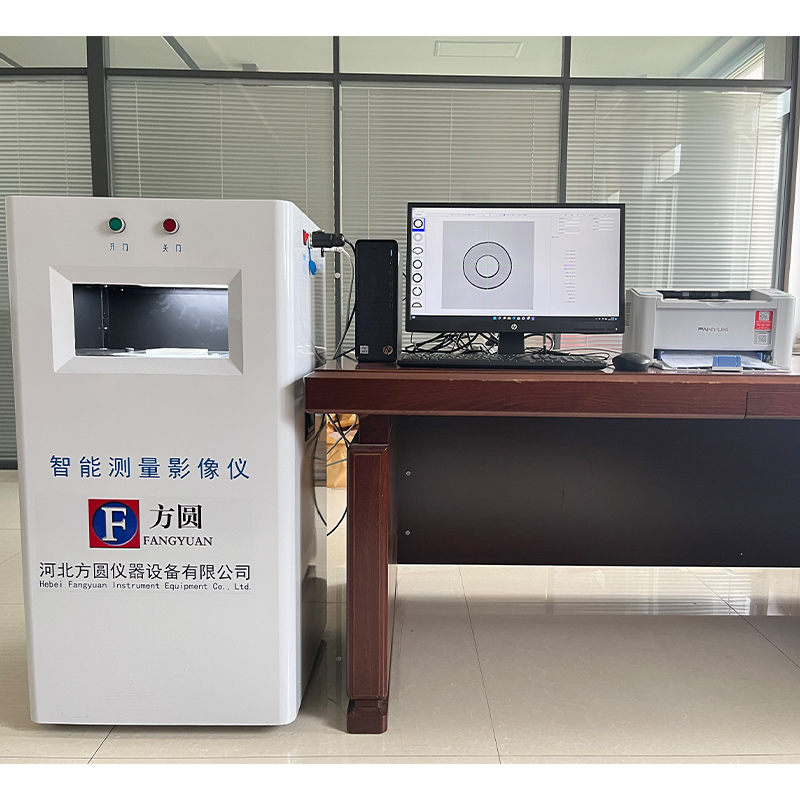

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy