homemade tensile strength tester manufacturers

Exploring Homemade Tensile Strength Testers A Surge in DIY Manufacturing

In the realm of materials science and engineering, the importance of tensile strength cannot be overstated. This fundamental property determines how materials will behave under tension, making it crucial for applications ranging from construction to consumer goods. While professional tensile strength testers manufactured by established brands provide precise measurements, a growing trend has emerged the creation and use of homemade tensile strength testers. This article delves into the motivations behind these DIY projects, the basic principles of their design, and the role of manufacturers supporting this trend.

The Appeal of Homemade Tensile Strength Testers

The movement towards homemade tensile strength testers arises from several factors. Firstly, accessibility is a major incentive. Not everyone can afford high-end, lab-grade testing equipment, which often costs thousands of dollars. For hobbyists, students, and small entrepreneurs, finding affordable testing solutions is essential. Homemade testers provide a practical alternative, allowing individuals to explore material properties without breaking the bank.

Moreover, the DIY culture thrives on creativity and resourcefulness. Building a tensile strength tester from scratch not only empowers individuals to better understand material behavior but also fosters innovation. By engaging in the process, makers can experiment with different materials and configurations, leading to unique designs that may offer insights that commercial products don’t.

Principles of Tensile Strength Testing

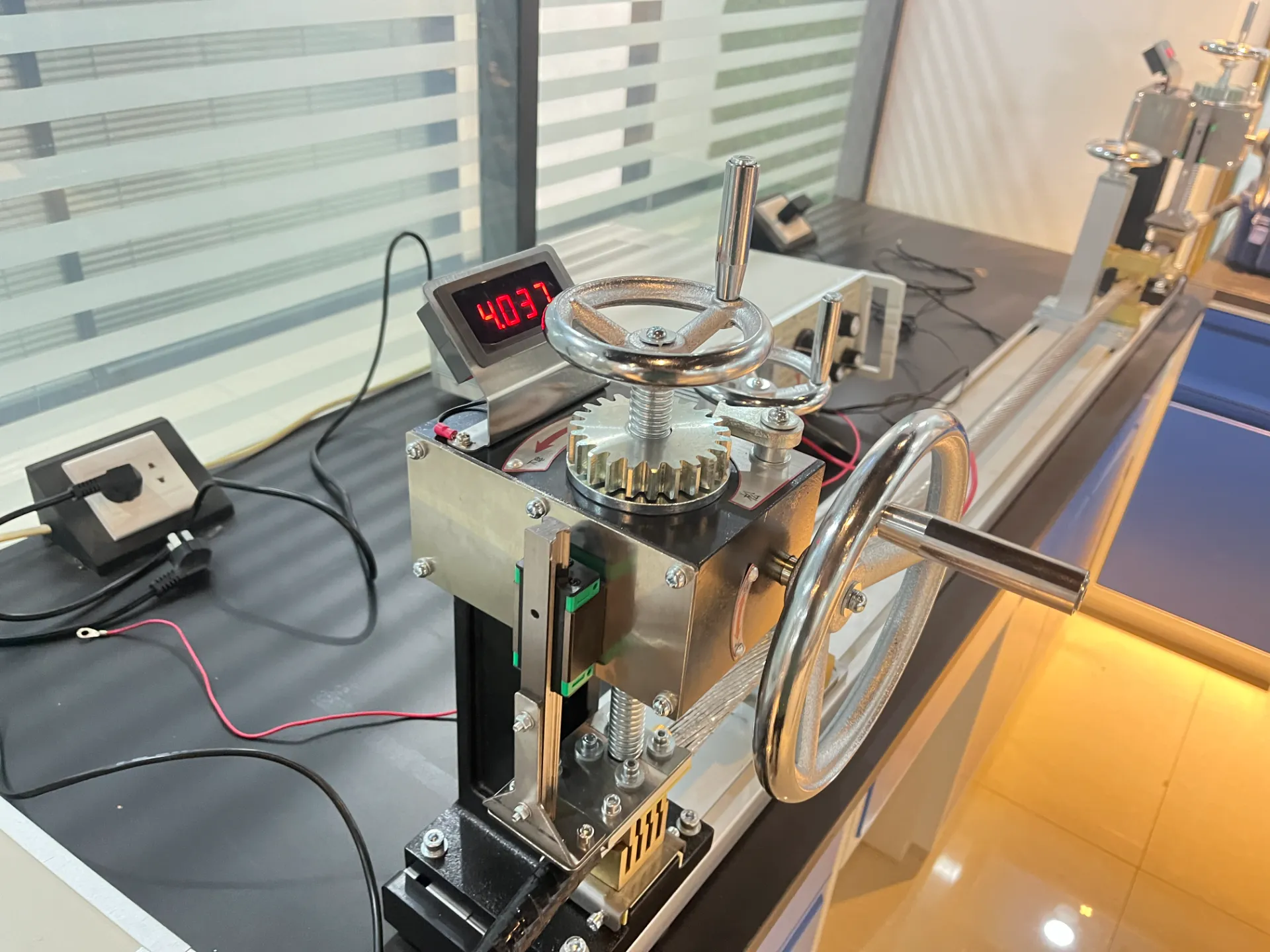

At its core, tensile strength testing involves applying a force to a material until it breaks and measuring the resistance it offers. A basic tensile strength tester may consist of a testing frame, clamps to hold the material, and a load cell or weight system to apply tension. Some homemade designs include intricate mechanisms to record the data, integrating software and sensors for enhanced accuracy.

The essential components of a homemade tensile strength tester include

1. Testing Frame The structure must be robust enough to withstand the forces applied. Many DIY enthusiasts use materials such as wood, metal, or PVC pipes to create the frame. 2. Clamping System Securely holding the test material is critical. Clamps can be made from simple materials but need to provide firm grip without damaging the specimen.

homemade tensile strength tester manufacturers

3. Load Application Mechanism This can vary greatly in complexity. Some builders use weights, while others opt for hydraulic or pneumatic systems to apply force incrementally.

4. Measurement Device While high-tech solutions like digital force gauges can be pricey, simpler methods such as using a ruler combined with weights can suffice for basic tensile strength testing.

Supporting Manufacturers and Resources

As the interest in homemade tensile strength testers increases, so does the support from manufacturers and resource providers. Several companies have recognized the demand for DIY components, offering kits that include essential parts designed to help individuals build their own testers effectively. These kits often contain pre-manufactured components, making assembly easier while still allowing for customization.

Additionally, online forums and communities have flourished, serving as platforms for knowledge exchange and troubleshooting. Websites, social media groups, and video tutorials provide detailed guidance on the building process, making it easier for novices to embark on their own testing endeavors. These resources empower users to enhance their knowledge and skills in material testing, promoting a deeper understanding of engineering principles.

The Future of DIY Testing

As technology evolves, so too will the capabilities of homemade tensile strength testers. The integration of software and smartphones may lead to more advanced data collection and analysis, democratizing the access to material testing further. For educational institutions, these DIY projects provide hands-on learning experiences that are invaluable in fostering a new generation of engineers and scientists.

In conclusion, the rise of homemade tensile strength testers represents a unique intersection of creativity, education, and engineering. While professional testing equipment remains indispensable for industry applications, the DIY approach offers a platform for experimentation and learning. With support from manufacturers and the growing availability of resources, building a homemade tensile strength tester is more feasible than ever, empowering individuals to explore the fascinating world of material science.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy