hydraulic conductor resistance fixture factories

Understanding Hydraulic Conductor Resistance Fixture Factories

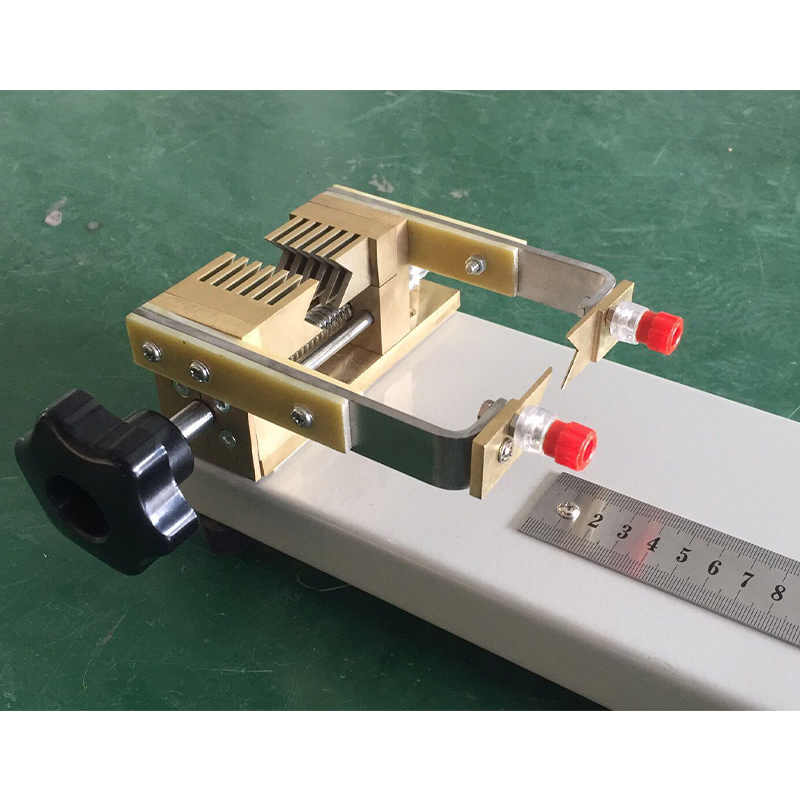

In the realm of engineering and manufacturing, hydraulic systems play a pivotal role in enhancing the efficiency and effectiveness of various applications. One critical component of these systems is the hydraulic conductor resistance fixture. These fixtures are designed to test and measure the resistance of hydraulic conductors, ensuring they meet the necessary specifications and performance standards. This article delves into the significance of hydraulic conductor resistance fixture factories, their contributions to the industry, and the technology behind these essential devices.

The Importance of Hydraulic Conductors

Hydraulic conductors are crucial for the transfer of fluids within hydraulic systems, enabling the operation of machinery and equipment across diverse sectors, including construction, automotive, aerospace, and manufacturing. The reliability of these conductors is paramount, as any failure can lead to catastrophic outcomes, such as system malfunctions or accidents. This is where hydraulic conductor resistance fixture factories come into play, providing the necessary tools to ensure that conductors are produced to the highest standards of quality and durability.

The Role of Resistance Testing

Resistance testing involves evaluating the electrical resistance of hydraulic conductors under various conditions. This assessment is crucial because it helps identify any potential issues such as leaks, blockages, or material fatigue that could compromise the conductor's performance. Factories specializing in hydraulic conductor resistance fixtures develop sophisticated testing systems that can simulate real-world conditions, allowing manufacturers to assess the integrity and functionality of their products before they reach the market.

Technological Advancements in Fixture Manufacturing

Hydraulic conductor resistance fixture factories are at the forefront of technological advancements. The integration of automation and precision engineering has revolutionized the production of testing fixtures. Modern factories employ Computer Numerical Control (CNC) machines, which offer unmatched accuracy and consistency in manufacturing. Additionally, advanced materials and smart technologies, such as sensors and data analytics, are incorporated into testing fixtures to enhance performance and reliability.

hydraulic conductor resistance fixture factories

These innovations not only streamline the manufacturing process but also enable factories to produce customized testing solutions that cater to the unique requirements of different hydraulic systems. By providing tailored fixtures, manufacturers can ensure that their products meet or exceed industry standards, fostering trust and safety in hydraulic applications.

Quality Assurance in Manufacturing

Quality assurance is a cornerstone of the operations in hydraulic conductor resistance fixture factories. Rigorous testing protocols are implemented at every stage of the manufacturing process, from the initial design to the final product. This involves conducting extensive evaluations and calibrations to ensure that each fixture performs accurately and reliably. Furthermore, factories often adhere to international quality standards and certifications, guaranteeing that their products meet the stringent safety and performance criteria expected in the industry.

The Future of Hydraulic Conductor Resistance Fixtures

The future of hydraulic conductor resistance fixture factories appears promising. With ongoing advancements in materials science, automation, and IoT (Internet of Things), the potential for more efficient and effective testing solutions is vast. Factories are increasingly investing in research and development to create fixtures that not only meet current demands but also anticipate future challenges in the hydraulic industry.

Moreover, as industries shift towards sustainable practices and eco-friendly materials, these factories are exploring innovative ways to minimize waste and promote sustainability in their manufacturing processes.

Conclusion

In conclusion, hydraulic conductor resistance fixture factories play an indispensable role in ensuring the reliability and safety of hydraulic systems. Through advanced testing technologies and rigorous quality assurance processes, these factories contribute significantly to the overall performance of hydraulic conductors. As the industry continues to evolve, the role of these factories in supporting innovation and maintaining high standards will be more critical than ever, paving the way for safer and more efficient hydraulic applications across various sectors.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy