Supplier for Hydraulic Conductor Resistance Testing Equipment and Fixtures

Understanding Hydraulic Conductor Resistance Fixture Suppliers

In the realm of hydraulic systems, the importance of reliable components cannot be overstated. One such critical component is the hydraulic conductor resistance fixture. This device plays a pivotal role in ensuring that hydraulic systems operate efficiently and safely. But what exactly is a hydraulic conductor resistance fixture, and why are suppliers of these fixtures crucial to the performance of hydraulic systems?

What is a Hydraulic Conductor Resistance Fixture?

A hydraulic conductor resistance fixture is a specialized apparatus designed to measure the electrical resistance of hydraulic conductors. These fixtures are essential for testing components in hydraulic systems, such as hoses, tubes, and fittings, to ensure that they meet specific industry standards. The resistance measurements obtained can indicate the overall integrity of hydraulic components, ensuring they are capable of withstanding the rigorous demands placed on them during operation.

The Importance of Resistance Measurement

Measuring electrical resistance in hydraulic systems is vital for several reasons. First, excessive resistance can lead to inefficient operation, resulting in energy losses and increased operational costs. Second, resistance measurements can pinpoint potential failures before they result in catastrophic breakdowns. By detecting issues early, operators can carry out preventive maintenance, thereby extending the life of hydraulic systems and reducing downtime.

Choosing a Reliable Supplier

When selecting a supplier for hydraulic conductor resistance fixtures, several factors should be considered

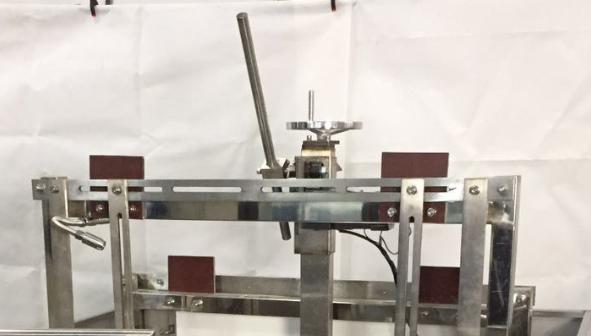

hydraulic conductor resistance fixture supplier

1. Quality and Standard Compliance The fixtures should conform to international standards and regulations, ensuring that they provide accurate and reliable measurements. Suppliers should provide certifications and documentation that prove their products meet industry requirements.

2. Range of Products A reputable supplier will offer a range of hydraulic conductor resistance fixtures to cater to various applications. This includes different sizes, capabilities, and measurement technologies to suit specific needs.

3. Technical Support and Expertise Suppliers who offer technical assistance can be invaluable. Their expertise can help customers understand the optimal use of the fixtures and troubleshoot any problems that may arise during testing.

4. Customer Reviews and Reputation Researching a supplier’s reputation through customer reviews and testimonials can provide insights into their reliability and service quality. A supplier known for excellent customer service and support will ensure a smoother purchasing experience.

The Role of Innovation

As hydraulic systems evolve, so too must the tools and fixtures used to test them. Innovative suppliers are continually researching and developing new technologies to enhance the performance and accuracy of hydraulic conductor resistance fixtures. This might include advancements in digital measurement tools, automation, and data analysis capabilities that can provide more comprehensive insights into system performance.

Conclusion

In conclusion, hydraulic conductor resistance fixtures are essential for maintaining the efficiency and safety of hydraulic systems. The role of suppliers in this niche market is crucial; they not only provide the equipment necessary for accurate testing but also contribute to the overall reliability and performance of hydraulic systems. As industries continue to demand greater reliability and efficiency, the relationship between hydraulic component manufacturers and fixture suppliers will only grow more integral to successful operations. Those involved in hydraulic system maintenance and testing should prioritize partnerships with reputable suppliers to ensure they have access to the best tools available in the industry.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy