hydraulic resistance fixture

Understanding Hydraulic Resistance Fixtures Principles and Applications

Hydraulic resistance fixtures play a crucial role in various engineering applications, serving as essential components in the study and management of fluid behavior within hydraulic systems. These fixtures are specifically designed to measure the resistance that fluid encounters when flowing through them. By analyzing hydraulic resistance, engineers can optimize systems for efficiency, safety, and performance.

At the core of hydraulic resistance fixtures lies the principle of fluid dynamics. When a fluid flows through a pipe or a fitting, it encounters resistance due to factors such as viscosity, turbulence, and surface roughness. This resistance can be quantified using the Darcy-Weisbach equation, which relates the pressure loss in a fluid flow to the velocity of the fluid, the friction factor, and the length and diameter of the pipe. Hydraulic resistance fixtures are thus designed to simulate various flow conditions and gather precise data on how different parameters affect fluid behavior.

One common application of hydraulic resistance fixtures is in the testing of new materials and designs in automotive and aerospace engineering

. By using these fixtures, engineers can evaluate the performance of different components under various flow conditions, ensuring that they meet safety and efficiency standards. For example, the fixture can help analyze the hydraulic resistance of brake systems or fuel lines, allowing for optimization before mass production.hydraulic resistance fixture

Moreover, hydraulic resistance fixtures are essential in research settings, where scientists investigate complex fluid dynamics phenomena. They enable the examination of laminar and turbulent flow characteristics, providing insights into how fluids behave under different conditions. These findings are invaluable in industries ranging from civil engineering, where they aid in designing pipelines and water treatment facilities, to biomedical applications, where fluid flow in the human body is studied.

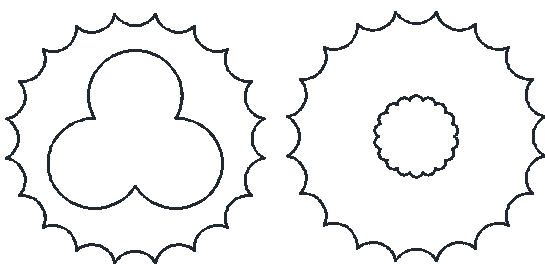

The design of hydraulic resistance fixtures can vary significantly, depending on the specific requirements of the experiment or application. Some fixtures are straightforward, consisting of simple pipes and connectors, while others are more sophisticated, equipped with sensors and instruments for real-time data collection and analysis.

In conclusion, hydraulic resistance fixtures are indispensable tools in both industry and research. By providing critical insights into fluid dynamics, they help engineers and scientists design more efficient systems, enhance safety measures, and foster innovation across various fields. As technology progresses, the design and functionality of hydraulic resistance fixtures will continue to evolve, further advancing our understanding of fluid behavior and its applications.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy