Understanding IEC 60811 Standards for Insulation and Sheathing Materials in Factories

Understanding IEC 60811 The Standard for Insulation and Sheath Materials

The IEC 60811 standard, created by the International Electrotechnical Commission (IEC), outlines the test methods for insulating and sheathing materials used in cables for electrical installations. This standard is crucial as it ensures the safety and performance of electrical systems by establishing guidelines for material properties and quality control.

Importance of IEC 60811

The significance of IEC 60811 cannot be overstated, especially in an era where advanced technologies and energy-efficient solutions are in high demand. Insulation and sheath materials are vital components of electric cables, acting as barriers to prevent short circuits, reduce energy loss, and enhance the overall durability of electrical systems. By adhering to IEC 60811, manufacturers can ensure that their products meet international safety standards, thereby safeguarding both people and equipment.

Key Aspects of the Standard

IEC 60811 primarily focuses on the testing of various properties of materials, including mechanical, thermal, and electrical characteristics. Some of the significant tests outlined in this standard include

1. Mechanical Properties This includes assessments of tensile strength, elongation at break, and impact resistance. These properties are critical for ensuring that the materials can withstand environmental stressors such as bending, pulling, and thermal expansion.

2. Thermal Properties The standard specifies tests for heat resistance, which is vital given that cables can generate heat during operation. Understanding the thermal behavior of materials helps prevent degradation over time, which can lead to electrical failures.

iec60811 factories

3. Electrical Properties Insulation resistance is a critical concern in the design of electric cables. IEC 60811 provides methods for measuring breakdown voltage and insulation resistance, ensuring that materials can effectively isolate conductive parts and prevent leakage currents.

4. Chemical Resistance Exposure to various chemicals is common in certain environments, such as industrial settings. The standard outlines tests to ensure that materials can withstand corrosive substances without losing their protective qualities.

5. Environmental Considerations IEC 60811 also addresses the impact of environmental factors, such as moisture and UV radiation. Materials need to perform reliably in diverse conditions, and the standard provides guidance on testing for these aspects.

Application in Manufacturing

Manufacturers who comply with IEC 60811 not only adhere to international standards but also enhance their marketability. Products that bear the IEC certification are more likely to be trusted by consumers, as they indicate a commitment to quality and safety. Additionally, compliance with this standard can facilitate international trade by ensuring mutual recognition of product quality among countries.

Conclusion

In summary, IEC 60811 serves as a foundational standard in the cable manufacturing industry, providing essential guidelines for the testing of insulating and sheathing materials. The emphasis on mechanical, thermal, electrical, and chemical properties helps ensure that electrical cables perform safely and efficiently under various conditions. As the demand for reliable and high-quality electrical systems continues to grow, the role of standards like IEC 60811 becomes increasingly vital in fostering innovation, safety, and excellence within the industry. By adhering to these standards, manufacturers not only protect their consumers but also contribute to the development of a safer and more efficient electrical infrastructure worldwide.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

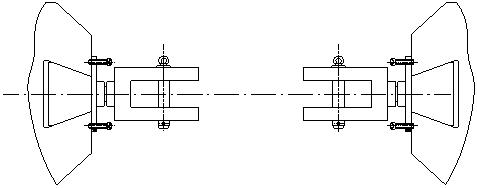

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy