insulation resistance tests factories

Understanding Insulation Resistance Tests in Factories

Insulation resistance tests are critical in ensuring the safety and efficiency of electrical systems in factories. These tests evaluate the integrity of insulation materials used in electrical wiring and equipment, helping to prevent potential electrical failures and hazards that could lead to costly downtime or accidents.

In a factory setting, machines and equipment operate continuously, often under harsh conditions. Over time, insulation can degrade due to factors such as temperature fluctuations, moisture, dust, and mechanical stress. Insulation resistance tests play a crucial role in identifying weaknesses in insulation before they lead to equipment failures.

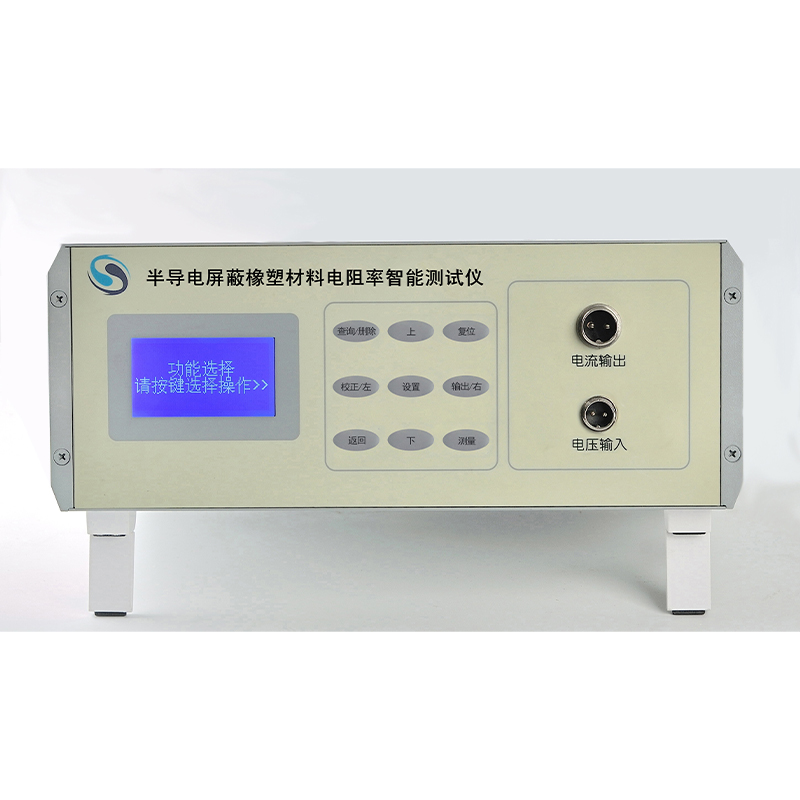

The basic principle behind insulation resistance testing is to apply a known voltage to the insulation material while measuring the resultant leakage current. This process helps to determine the resistance of the insulation. A high insulation resistance value indicates a good condition, while a low value signals potential problems.

insulation resistance tests factories

Typically, insulation resistance tests are performed using a megohmmeter, an instrument specifically designed to measure high resistance values. The testing process involves disconnecting the equipment from the power supply to ensure safety, connecting the megohmmeter to the insulation, and applying a test voltage, usually ranging from 250V to 1000V, depending on the system voltage. The readings obtained from the test provide valuable insights into the insulation's condition and any necessary maintenance or repairs.

Regular insulation resistance testing is essential in factories as part of a comprehensive preventive maintenance program. By implementing these tests routinely, facilities can identify insulation degradation early, thereby minimizing the risk of electrical failures. This proactive approach not only ensures the safety of personnel but also enhances operational efficiency by reducing unexpected downtime.

Furthermore, insulation resistance tests are often required for compliance with safety standards and regulations. Adherence to these guidelines not only protects workers but also safeguards against potential legal ramifications and financial liabilities associated with electrical accidents.

In conclusion, insulation resistance testing is a vital practice in factory environments. By regularly assessing the integrity of insulation, facilities can prevent equipment failures, enhance safety, and ensure compliance with industry standards. Investing in these tests is not merely a regulatory necessity; it is a strategic move that can lead to enhanced productivity and safety in manufacturing operations.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy