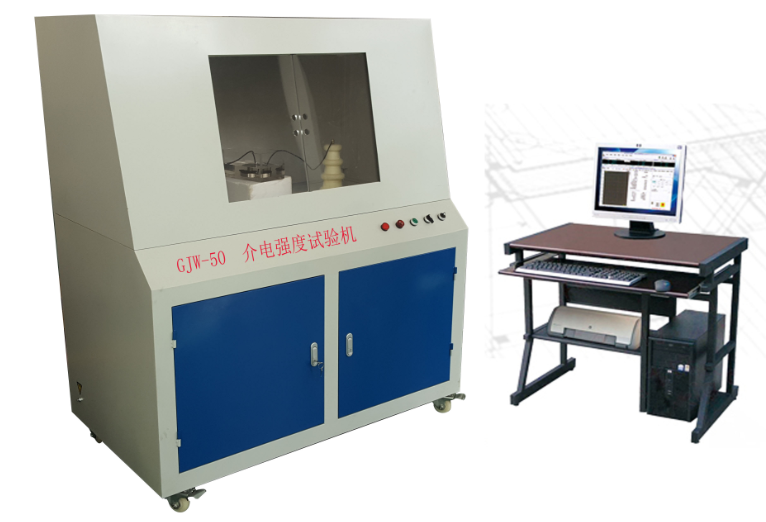

insulation resistance testers

Understanding Insulation Resistance Testers

Insulation resistance testers play a crucial role in maintaining safety and efficiency in electrical systems. These devices measure the resistance offered by electrical insulation to the flow of current, ensuring that the insulation is intact and effective. Understanding the importance, functionality, and proper usage of insulation resistance testers is essential for anyone involved in electrical maintenance and safety.

Importance of Insulation Resistance Testing

Electrical insulation is vital in preventing current leaks that could lead to short circuits, equipment failures, or hazardous situations such as electrical fires. Over time, insulation can degrade due to environmental factors, mechanical stress, or physical damage. Therefore, regular testing is essential to identify potential issues before they escalate. Insulation resistance testing helps in verifying that electrical systems and components comply with safety standards and regulations, ensuring the protection of both equipment and personnel.

How Insulation Resistance Testers Work

Insulation resistance testers, commonly referred to as megohmmeters, apply a high voltage to the insulation material and measure the resistance in ohms. The basic principle is to apply a known voltage to the circuit and measure the leakage current that flows through the insulation. This measurement is then converted to insulation resistance, typically expressed in megohms (MΩ). Higher resistance values indicate better insulation quality, while lower values can indicate potential faults or deterioration.

Most insulation testers operate at voltages ranging from 250V to 5kV. This range allows testing of various equipment, including cables, transformers, and motors. When testing, it's essential to disconnect the equipment from any power source to ensure accurate readings and avoid damage to the tester.

Key Features to Look For

insulation resistance testers

When selecting an insulation resistance tester, several features should be considered

1. Voltage Range Ensure the tester can accommodate the voltage level of the equipment being tested. 2. Accuracy Look for devices with high accuracy ratings for reliable measurements. 3. Data Logging Many modern testers offer data logging capabilities, which are useful for tracking insulation resistance over time and identifying trends. 4. Safety Features Child lock functions and automatic discharge capabilities enhance safety during and after testing. 5. Portability Lightweight and compact designs make it easier to carry and use in various settings.

Best Practices for Testing

To achieve accurate results while using insulation resistance testers, follow these best practices

- Preparation Ensure the equipment is de-energized and properly isolated. - Calibration Regularly calibrate the tester for accurate performance. - Multiple Tests Conduct tests at different voltages and compare results to ensure consistency. - Interpretation of Results Understand that acceptable resistance values can vary depending on the type of equipment and its application. Generally, insulation resistance values above 1 MΩ are considered acceptable, but specific standards may define different thresholds.

Conclusion

Insulation resistance testers are indispensable tools in the field of electrical maintenance and safety. By regularly measuring insulation resistance, professionals can ensure the reliability of electrical systems and prevent potential hazards. Investing in a reliable and feature-rich insulation resistance tester is essential for any organization dedicated to maintaining electrical safety standards. Regular testing not only complies with regulatory requirements but also extends the lifespan of electrical equipment, ensuring optimal performance and safety.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy