Testing Companies Specializing in Insulation Resistance Services and Solutions

Understanding Insulation Resistance Tests A Key Service by Specialized Companies

In the realm of electrical engineering and safety management, insulation resistance testing plays a crucial role in ensuring the reliability and safety of electrical installations. It is a vital process carried out by specialized companies that focus on providing high-quality testing services. This article delves into the importance of insulation resistance tests, the methodologies employed, and how these tests contribute to the overall safety of electrical systems.

What is Insulation Resistance Testing?

Insulation resistance testing is a method used to evaluate the integrity of an electrical system's insulation. The primary aim is to measure the resistance of electrical insulation to prevent current leakage, which can lead to serious hazards such as electrical shock, equipment damage, or even fires. The tests typically involve applying a high-voltage signal to the equipment and measuring the resistance of the insulation. A high resistance value indicates good insulation, while a low value suggests potential problems.

Why Insulation Resistance Testing is Important

1. Safety Assurance The foremost reason for conducting insulation resistance tests is to safeguard personnel and equipment. Malfunctioning insulation can lead to dangerous situations, including electric shocks. Regular testing minimizes these risks.

2. Preventive Maintenance Insulation resistance tests are an integral part of preventive maintenance programs. By identifying insulation degradation early, companies can take corrective measures before issues escalate into costly repairs or replacements.

3. Regulatory Compliance Many industries are subject to stringent regulations requiring periodic testing of electrical systems. Ensuring compliance with these regulations protects organizations from legal liabilities and promotes workplace safety.

4. Operational Efficiency Well-maintained insulation enhances the overall efficiency of electrical systems. By preventing unexpected breakdowns, companies can maintain productivity and reduce downtime, saving both time and resources.

The Testing Process

A trusted insulation resistance testing company typically follows a systematic approach to ensure thorough evaluations. The process usually involves the following steps

1. Visual Inspection Before conducting tests, a visual examination of the electrical equipment is performed. This step helps to identify any visible signs of damage, corrosion, or wear that may affect test results.

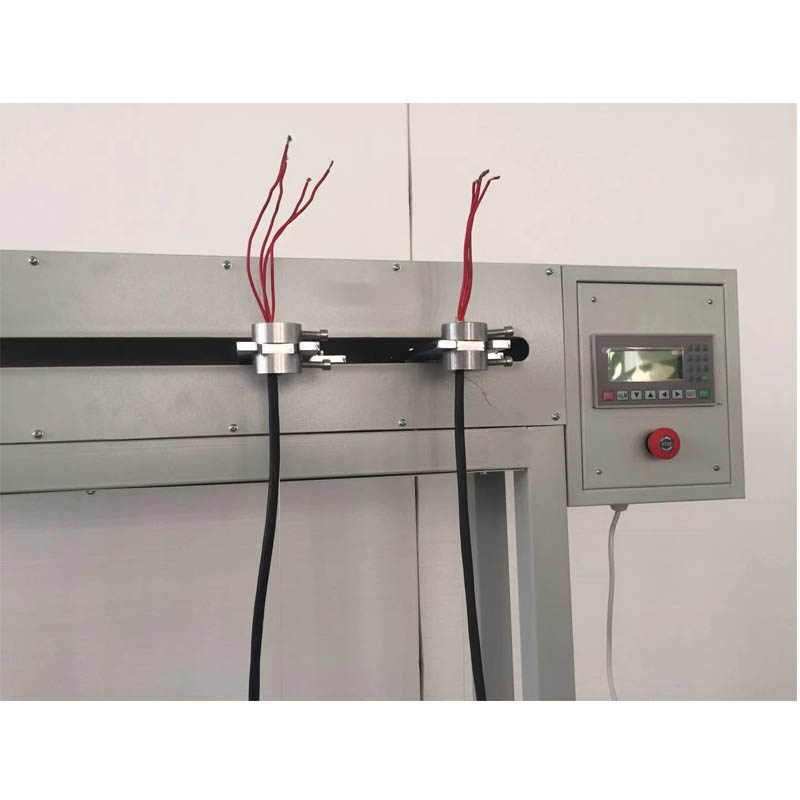

insulation resistance tests company

2. Setting Up Equipment The testing team sets up the insulation resistance tester, which is capable of applying a specific voltage—often ranging from 100V to 1000V—depending on the system under test.

3. Performing the Test The tester is connected to the insulation material and power source. It applies the high voltage while measuring the resulting current flow. The insulation resistance is calculated using Ohm's law.

4. Data Analysis The results are analyzed to determine the insulation's health. A resistance value above the threshold (typically 1 megohm or higher, subject to industry standards) indicates that the insulation is in good condition.

5. Reporting Finally, the testing company provides a comprehensive report, detailing findings, recommendations, and any necessary corrective actions.

Choosing the Right Testing Company

Selecting the right insulation resistance testing company is crucial for effective results. Here are some factors to consider

- Experience and Expertise Look for companies with a proven track record and specialized knowledge in the field. Experienced technicians can provide more accurate assessments and recommendations.

- Accreditation and Certifications Ensure that the company adheres to relevant industry standards and possesses the necessary certifications. This guarantees that testing procedures meet established guidelines.

- Advanced Equipment A reliable testing company should utilize modern, calibrated equipment capable of performing various tests efficiently.

- Customer Support Consider companies that offer excellent customer service, including pre-and post-test support. A good relationship fosters trust and better communication regarding test results and necessary actions.

Conclusion

In conclusion, insulation resistance testing is essential for maintaining the safety and efficiency of electrical systems. Companies specializing in these tests offer invaluable services that protect both personnel and equipment. By understanding the importance of these tests and selecting a reputable testing company, organizations can ensure compliance with regulations, enhance safety, and improve the lifespan of their electrical systems. In an ever-evolving technological landscape, investing in insulation resistance testing is not just a precaution—it's a necessity for any organization that values safety and operational excellence.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy