Understanding Insulation Resistance Testing Methods and Best Practices for Manufacturers

Understanding Insulation Resistance Tests A Comprehensive Guide for Manufacturers

In the realm of electrical engineering, insulation resistance tests play a vital role in ensuring the safety and reliability of electrical systems. Manufacturers of electrical equipment need to understand the importance of insulation resistance testing and its implications on product quality and safety. This article delves into the details of insulation resistance tests, their significance, and the factors manufacturers should consider to maintain high standards.

What is Insulation Resistance Testing?

Insulation resistance testing involves measuring the resistance of electrical insulation to determine its effectiveness at preventing current leakage. This procedure is typically performed using an insulation resistance tester, which applies a high voltage to the insulation material and measures the resistance value in ohms. A higher resistance value indicates better insulation quality, while a lower value may signal deterioration or potential failure.

Importance of Insulation Resistance Testing

1. Safety Compliance Electrical safety regulations necessitate that manufacturers carry out insulation resistance tests to conform to industry standards. This helps in protecting users from electrical shocks, short circuits, and potential fires due to faulty insulation.

2. Quality Assurance Regular testing ensures that electrical components meet the specified performance criteria. It aids manufacturers in identifying defective parts early in the production process, thus safeguarding the overall quality of the end product.

3. Preventative Maintenance Insulation resistance tests can also serve as a predictive maintenance tool. By regularly checking the insulation resistance of equipment, manufacturers can detect insulation wear and tear before it leads to equipment failure, ultimately extending the lifespan of the device.

Recommended Practices for Manufacturers

insulation resistance tests manufacturer

To effectively implement insulation resistance testing, manufacturers should adhere to the following best practices

1. Use Calibrated Equipment Ensure that insulation resistance testers are properly calibrated and maintained. Regular calibration guarantees accurate readings, which are essential for interpreting the condition of insulation correctly.

2. Develop a Testing Schedule Establish a regular testing schedule for all equipment involved in production. This schedule should be aligned with the manufacturer's operational demands and maintenance plans to ensure that the testing does not hinder productivity.

3. Train Personnel Adequately train staff on the significance of insulation resistance tests and the correct procedures for conducting them. Competence in interpreting results is crucial in making informed decisions about the insulation quality.

4. Document Results Maintaining thorough records of insulation resistance test results allows for trend analysis over time. This documentation can help in recognizing patterns that may indicate potential issues, facilitating proactive interventions.

5. Implement Corrective Actions When low resistance readings are obtained, manufacturers must investigate the causes and implement necessary corrective actions. This could involve replacing insulation, improving manufacturing processes, or enhancing material quality.

Conclusion

Insulation resistance tests are a fundamental aspect of electrical manufacturing that cannot be overlooked. The importance of ensuring proper insulation cannot be understated, as it directly impacts the safety, reliability, and longevity of electrical equipment. By adopting best practices in insulation resistance testing, manufacturers can not only meet regulatory requirements but also uphold quality standards that reflect positively on their brand reputation. In a world increasingly reliant on electrical systems, the commitment to safety and quality begins with effective insulation resistance testing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

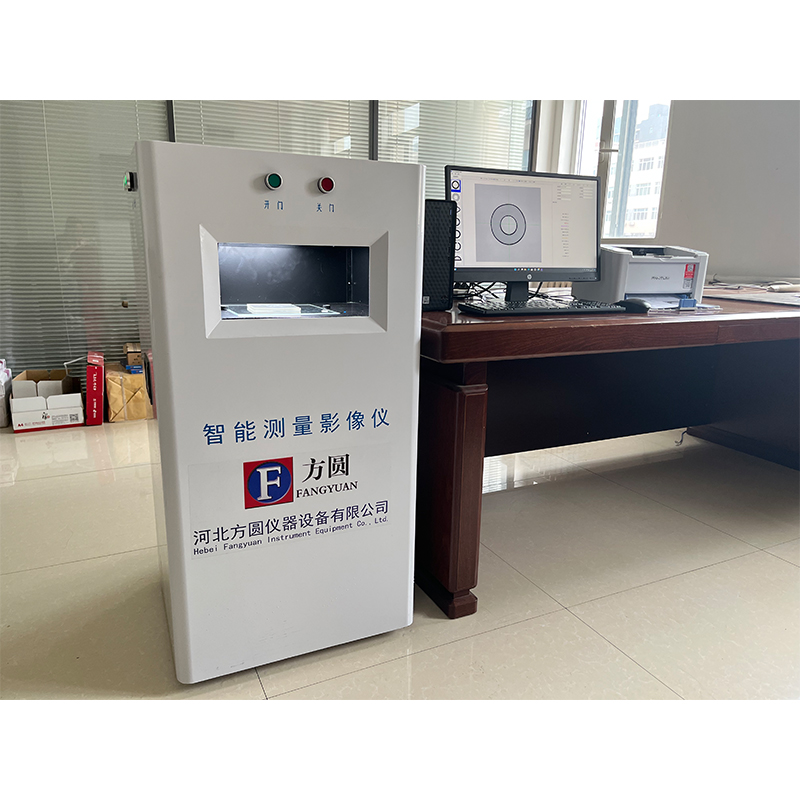

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy