JR-N-16/16S Wire Winding & Torsion Tester: Precision Wire Durability

Industry Trends and the Imperative for Precision Testing

The global wire and cable market is experiencing robust growth, driven by escalating demand in sectors such as renewable energy, telecommunications (especially 5G), electric vehicles, and smart infrastructure. According to a report by Grand View Research, the global wire and cable market size was valued at approximately USD 205.4 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.0% from 2023 to 2030. This expansion brings with it an amplified need for superior material quality and manufacturing consistency.

Emerging trends, such as miniaturization, higher current capacities, increased operational temperatures, and the integration of advanced materials (e.g., superconductors, composite materials), necessitate more rigorous and precise testing methodologies. Traditional quality control checks are no longer sufficient to meet the challenges posed by these innovations. Manufacturers are increasingly prioritizing testing equipment that can accurately assess critical mechanical properties like ductility, tensile strength, and resistance to repetitive stress, which are crucial for preventing premature failure in diverse operational environments. This makes the **JR-N-16/16S Wire Winding And Torsion Test Machine** an indispensable asset.

Failure to perform adequate testing can lead to costly product recalls, reputational damage, and, in critical applications, catastrophic safety hazards. Therefore, investing in reliable and accurate testing solutions, such as the **JR-N-16/16S Wire Winding And Torsion Test Machine**, is not merely a compliance requirement but a strategic imperative for long-term success and market leadership.

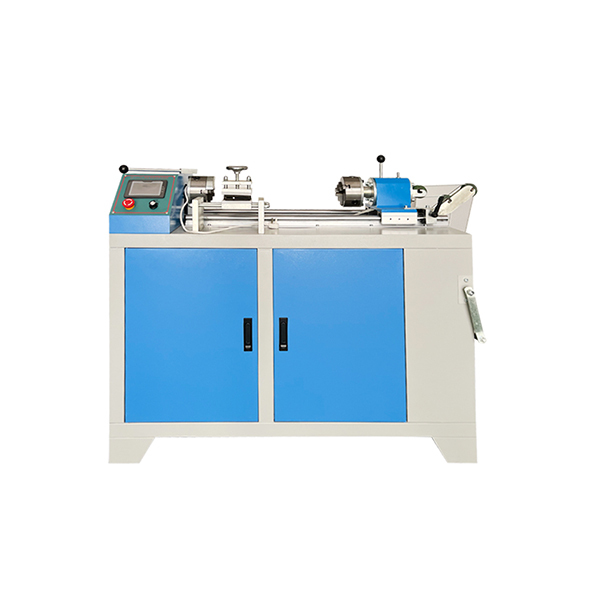

Fig 1: The **JR-N-16/16S Wire Winding And Torsion Test Machine** in a laboratory setting.

Technical Parameters and Specifications

The **JR-N-16/16S Wire Winding And Torsion Test Machine** is engineered to deliver precise and repeatable results for evaluating the winding and torsion properties of various wire types. Its robust design and advanced control system make it suitable for a wide range of industrial applications. Below is a detailed table outlining its key technical parameters:

| Parameter | Specification | Description |

|---|---|---|

| Model | **JR-N-16/16S** | Wire Winding and Torsion Test Machine |

| Wire Diameter Range | 0.1 mm - 16 mm | Accommodates a broad spectrum of wire gauges, from fine filaments to robust cables. |

| Winding Speed | 0 - 60 RPM (Adjustable) | Variable speed ensures compliance with diverse testing standards and material sensitivities. |

| Winding Turns Count | 0 - 999.9 (Digital Display) | High precision digital counter for exact measurement of winding cycles. |

| Torsion Angle Range | ±360° (Continuous Rotation) | Enables comprehensive evaluation of torsional ductility and fatigue. |

| Torsion Speed | 0 - 60 RPM (Adjustable) | Adjustable speed for controlled torsional testing, accommodating different material properties. |

| Accuracy | ±1% of Full Scale | Ensures highly reliable and consistent test results, critical for quality assurance. |

| Specimen Length | Adjustable, typically 50 mm - 500 mm | Flexibility in testing different sample lengths, as per specific standards. |

| Power Supply | AC 220V, 50/60Hz | Standard industrial power requirements. |

| Control System | Microprocessor-based with PC Software | Intuitive interface for test setup, data acquisition, and analysis. Features include real-time graphing, data logging, and report generation. |

| Dimensions (Approx.) | L800 x W600 x H1200 mm | Compact footprint for laboratory and production line integration. |

| Weight (Approx.) | 200 kg | Sturdy construction minimizing vibration and ensuring stability during operation. |

| Applicable Standards | ASTM B571, IEC 60888, JIS C3002, etc. | Designed to meet or exceed relevant international testing standards for wire and cable. |

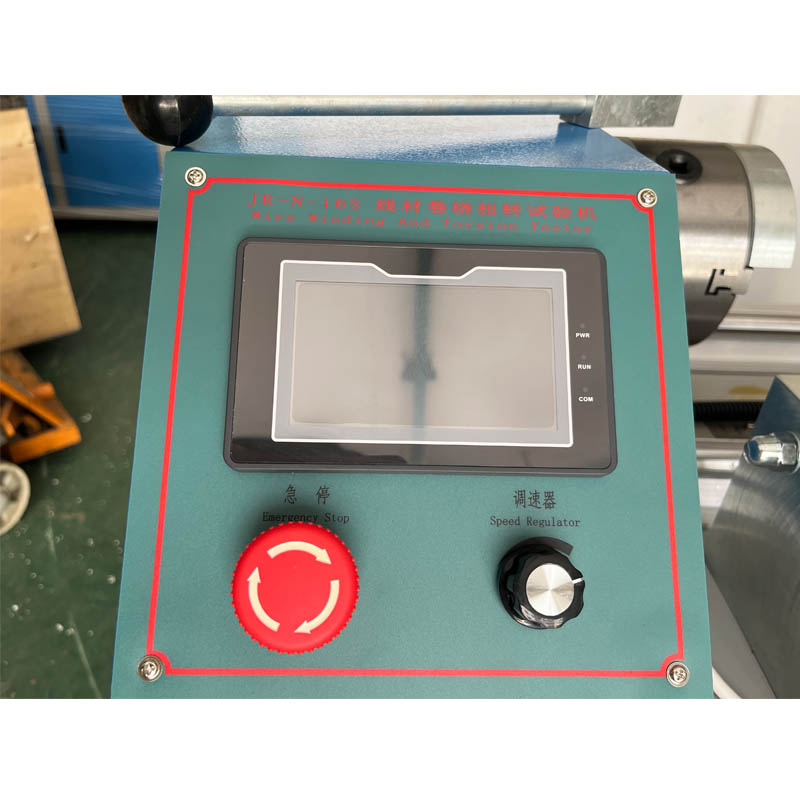

Fig 2: Close-up of the intuitive control interface of the **JR-N-16/16S Wire Winding And Torsion Test Machine**.

Detailed Manufacturing Process of the **JR-N-16/16S Wire Winding And Torsion Test Machine**

The manufacturing of the **JR-N-16/16S Wire Winding And Torsion Test Machine** is a meticulously controlled process, adhering to the highest standards of precision engineering and quality management (e.g., ISO 9001). This commitment ensures the longevity, reliability, and accuracy of every unit. Below is a detailed breakdown of the key manufacturing stages:

Design & Engineering Excellence

The journey begins with advanced CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems. Our engineering team utilizes Finite Element Analysis (FEA) to simulate structural integrity and optimize material distribution, ensuring maximum rigidity and minimal deflection under load. This stage defines the precise dimensions, component interactions, and ergonomic considerations for the **JR-N-16/16S Wire Winding And Torsion Test Machine**.

Premium Material Selection

Only high-grade materials are chosen for critical components. The main frame and structural elements typically utilize high-strength, anti-corrosion treated steel or aerospace-grade aluminum alloys, often manufactured through precision casting or forging for enhanced durability and shock resistance. Moving parts, such as lead screws and linear guides, are constructed from hardened tool steel, surface-treated (e.g., nitriding) for exceptional wear resistance. Gripping jaws, which interact directly with the wire samples, are made from specialized hardened alloys or carbide inserts, ensuring minimal deformation and consistent gripping force over countless tests. Electrical enclosures and control panels are often fabricated from robust sheet metal, powder-coated for superior corrosion protection and a sleek, durable finish.

Fig 3: A view illustrating the robust internal mechanisms and precision engineering of the **JR-N-16/16S Wire Winding And Torsion Test Machine**.

Precision Machining & Fabrication

Components undergo rigorous manufacturing processes including CNC (Computer Numerical Control) machining, which allows for extremely tight tolerances (e.g., ±0.005 mm) crucial for precise mechanical operation. This includes CNC milling for complex geometries, turning for cylindrical parts, and precision grinding for critical surfaces. Laser cutting and bending are employed for structural components, ensuring perfect fit and alignment. All processes are monitored to minimize material stress and maintain dimensional stability.

Advanced Assembly & Integration

Assembly of the **JR-N-16/16S Wire Winding And Torsion Test Machine** takes place in a controlled environment to prevent contamination. Highly skilled technicians perform meticulous manual assembly, integrating precision bearings, servo motors, encoders, and load cells. Critical alignments are verified using laser interferometry to ensure the mechanical system operates with minimal friction and maximum accuracy. The electrical and control systems are meticulously wired and interconnected, followed by initial power-on and functional checks.

Fig 4: A detailed view of a precision component within the **JR-N-16/16S Wire Winding And Torsion Test Machine**.

Calibration & Rigorous Testing

Each **JR-N-16/16S Wire Winding And Torsion Test Machine** undergoes multi-stage calibration and functional testing. Calibration is performed against traceable international standards, adhering to principles of ISO/IEC 17025 (General requirements for the competence of testing and calibration laboratories). This ensures the accuracy of winding turns, torsion angles, and speed control. Functional tests simulate various operational scenarios, pushing the machine to its limits to verify performance parameters, repeatability, and reliability under continuous operation. This includes testing against specific standards like ASTM B571 for winding tests and IEC 60888 for torsion tests on metallic wires.

Final Quality Control & Certification

Before shipment, every **JR-N-16/16S Wire Winding And Torsion Test Machine** undergoes a comprehensive final inspection. This includes visual checks, performance audits, software validation, and a detailed documentation review. Each machine is certified to meet its published specifications and applicable international standards, guaranteeing peak performance upon delivery. The robust construction and adherence to strict quality control measures contribute to an exceptional service life, typically exceeding 10 years with proper maintenance, ensuring a strong return on investment for our clients.

This meticulous manufacturing process, combined with the use of high-quality materials, ensures that the **JR-N-16/16S Wire Winding And Torsion Test Machine** delivers unparalleled accuracy, durability, and reliability for critical wire and cable testing applications.

Application Scenarios and Industry Advantages

The versatility and precision of the **JR-N-16/16S Wire Winding And Torsion Test Machine** make it an indispensable tool across numerous industries where wire and cable integrity is paramount. Its ability to perform both winding and torsion tests provides a comprehensive assessment of wire ductility, flexibility, and resistance to repeated mechanical stresses.

- Automotive Industry: In automotive wiring harnesses, wires are subjected to constant vibration, bending, and temperature fluctuations. The **JR-N-16/16S Wire Winding And Torsion Test Machine** ensures that wires used in engines, braking systems, and infotainment units can withstand the demanding operational environment, preventing electrical failures and enhancing vehicle safety.

- Aerospace & Defense: Wires in aircraft and spacecraft must endure extreme conditions, including wide temperature swings and intense vibrations. Testing with the **JR-N-16/16S Wire Winding And Torsion Test Machine** helps verify the high fatigue life and structural integrity of wires crucial for flight control, avionics, and communication systems, where failure is not an option.

- Electronics & Consumer Goods: From smartphones to home appliances, fine-gauge wires are ubiquitous. The machine's ability to test very thin wires (down to 0.1mm) is critical for ensuring the longevity of flexible circuits, internal wiring, and connectors, minimizing defects and improving product lifespan.

- Power Transmission & Distribution: High-voltage cables and overhead lines are exposed to environmental stresses and mechanical loads. The **JR-N-16/16S Wire Winding And Torsion Test Machine** aids in assessing the ductility and stress resistance of these heavy-duty wires, contributing to grid reliability and preventing outages.

- Medical Devices: Wires used in catheters, surgical tools, and implantable devices require exceptional flexibility, biocompatibility, and durability. The machine's precise control allows for testing of these specialized wires to meet stringent medical device regulations, ensuring patient safety and device functionality.

- Construction & Infrastructure: Steel reinforcement wires, pre-stressed concrete strands, and bridge cables require validation of their mechanical properties. The machine helps confirm their capacity to withstand long-term static and dynamic loads, essential for structural integrity and safety.

- Petrochemical & Metallurgy: In these industries, wires often operate in corrosive or high-temperature environments. The machine's robust design and ability to test various metallic wires contribute to ensuring the material integrity and long-term performance in harsh conditions, enhancing safety and operational efficiency.

In typical applications, the **JR-N-16/16S Wire Winding And Torsion Test Machine** excels by providing quick, accurate, and reproducible results. For instance, in a scenario demanding energy efficiency, its precise control over test parameters minimizes material waste during R&D, contributing to leaner manufacturing processes. Its robust construction ensures anti-corrosion properties crucial for longevity even in demanding industrial settings, minimizing downtime and maintenance costs. This direct impact on product quality and operational efficiency makes it a vital asset.

Fig 5: Demonstrating the ease of specimen loading and testing with the **JR-N-16/16S Wire Winding And Torsion Test Machine**.

Technical Advantages of the **JR-N-16/16S Wire Winding And Torsion Test Machine**

The **JR-N-16/16S Wire Winding And Torsion Test Machine** stands out in the market due to a suite of advanced features designed to maximize testing efficiency, accuracy, and user convenience. These technical advantages directly translate into tangible benefits for manufacturers and quality control laboratories:

- High Precision and Repeatability: Equipped with advanced servo motor drives and high-resolution encoders, the machine ensures exact control over winding turns and torsion angles. This precision is critical for obtaining repeatable results, which is foundational for reliable quality control and material research. The **JR-N-16/16S Wire Winding And Torsion Test Machine** boasts an accuracy of ±1% of full scale, a benchmark in its class.

- Wide Material Compatibility: The broad wire diameter range (0.1 mm to 16 mm) means it can test everything from delicate electronic wires to heavy-duty industrial cables, including copper, aluminum, steel, and various alloys. Its adaptable gripping mechanisms ensure secure and non-damaging clamping across this range.

- Intuitive Software & Data Analysis: The included PC-based software provides a user-friendly Human-Machine Interface (HMI) for effortless test parameter setup, real-time data visualization (graphing of angle vs. turns), and comprehensive data logging. Powerful analysis tools allow for statistical evaluation, comparison between batches, and automated report generation, streamlining quality assurance processes.

- Robust and Durable Construction: Built with industrial-grade components and high-quality materials (e.g., hardened steel, corrosion-resistant coatings), the machine is designed for continuous operation in demanding environments. This robust build contributes to a significantly extended service life and minimal maintenance requirements, ensuring a lower total cost of ownership.

- Compliance with International Standards: The **JR-N-16/16S Wire Winding And Torsion Test Machine** is engineered to comply with a variety of international testing standards, including ASTM B571 (Standard Test Method for Winding Test for Metallic Wire), IEC 60888 (Hot-Dip Galvanized Steel Wires for Overhead Power Lines), and JIS C3002 (Test methods of electrical wires and cables). This ensures test results are globally recognized and accepted.

- Safety Features: Incorporates essential safety mechanisms such as emergency stop buttons, overload protection, and protective covers, safeguarding both the operator and the equipment during testing operations.

Manufacturer Comparison: **JR-N-16/16S** vs. Competitors

Choosing the right testing equipment is a critical decision that impacts product quality, operational efficiency, and long-term cost. While several manufacturers offer wire winding and torsion testers, the **JR-N-16/16S Wire Winding And Torsion Test Machine** distinguishes itself through a combination of superior engineering, comprehensive features, and dedicated support. Below is a comparative analysis:

| Feature/Parameter | **JR-N-16/16S Wire Winding And Torsion Test Machine** | Competitor A (Entry-Level) | Competitor B (Premium) |

|---|---|---|---|

| Wire Diameter Range | 0.1 mm - 16 mm (Superior) | 0.5 mm - 10 mm (Limited) | 0.2 mm - 15 mm (Good) |

| Accuracy (Winding/Torsion) | ±1% FS (Excellent) | ±2% FS (Standard) | ±1.5% FS (Good) |

| Control System | PC-based with Advanced Software (Comprehensive) | Digital Display & Buttons (Basic) | PLC with Touchscreen (Good) |

| Data Analysis Capabilities | Real-time graphing, data logging, statistical analysis, custom reports (Extensive) | Manual recording, simple readings (Limited) | Basic data logging, limited graphing (Moderate) |

| Build Material & Durability | High-grade steel, CNC-machined components, corrosion-resistant finish (Premium) | Standard steel, basic machining (Adequate) | High-grade materials (Good) |

| Applicable Standards | ASTM, IEC, JIS compliant (Broad) | Limited to few basic standards (Narrow) | Major international standards (Good) |

| Service Life Expectancy | > 10 years (Exceptional) | 5-7 years (Typical) | 8-10 years (Good) |

| After-Sales Support | Global 24/7 technical support, remote diagnostics, on-site service options (Comprehensive) | Regional support, limited availability (Basic) | Standard support hours (Average) |

| Price Point | Mid-to-High (Excellent Value for Performance) | Low (Compromised Features) | High (Comparable Performance, Higher Cost) |

This comparison highlights that while entry-level options might seem appealing due to lower upfront costs, they often fall short in terms of accuracy, versatility, and long-term reliability. Premium competitors might offer similar performance but often at a significantly higher investment. The **JR-N-16/16S Wire Winding And Torsion Test Machine** strikes an optimal balance, providing superior performance, extensive features, and robust build quality at a highly competitive price point, making it a compelling choice for discerning professionals.

Fig 6: Example of typical test results and data visualization provided by the **JR-N-16/16S Wire Winding And Torsion Test Machine**'s software.

Customized Solutions and Application Cases

Recognizing that unique testing requirements exist across industries, we offer flexible and tailored solutions based on the robust platform of the **JR-N-16/16S Wire Winding And Torsion Test Machine**. Our team of experienced engineers works closely with clients to develop specific fixtures, software modifications, or integrated testing protocols.

Customization Capabilities:

- Specialized Grips and Fixtures: For wires with unusual profiles, coatings, or highly delicate properties, we can design and manufacture custom gripping jaws or winding mandrels to ensure accurate and non-damaging sample securement.

- Software Integration: Our software can be adapted for seamless integration with existing LIMS (Laboratory Information Management Systems) or MES (Manufacturing Execution Systems), allowing for automated data transfer and streamlined workflow.

- Environmental Chamber Compatibility: For tests requiring specific temperature or humidity conditions, the machine can be configured for integration with external environmental chambers, expanding its application scope to simulate real-world extreme conditions.

- Multi-Machine Control: For high-volume testing environments, a single PC can be configured to control multiple **JR-N-16/16S Wire Winding And Torsion Test Machines**, increasing throughput and operational efficiency.

Real-World Application Cases:

Case Study 1: Automotive Wiring Manufacturer

A leading automotive wiring harness manufacturer faced issues with wire fatigue in critical engine compartments, leading to intermittent electrical failures. They needed a reliable solution to test the long-term durability of their copper alloy wires under repetitive bending and torsion. Our customized **JR-N-16/16S Wire Winding And Torsion Test Machine**, equipped with specialized vibration simulation fixtures, allowed them to precisely replicate real-world operational stresses. Within six months, they identified a sub-standard wire batch, optimized their annealing process, and reduced field failures by 30%, resulting in significant cost savings and enhanced brand reputation. This successful deployment showcased our expertise in delivering solutions that directly address complex industry challenges.

Case Study 2: Medical Device Wire Supplier

A supplier of ultra-fine medical-grade stainless steel wires for minimally invasive surgical instruments required extremely precise torsion testing to ensure the wires could withstand repeated manipulation without kinking or breaking. The challenge was testing wires as thin as 0.15 mm with highly consistent torque application. We provided a modified **JR-N-16/16S Wire Winding And Torsion Test Machine** with micro-gripping capabilities and enhanced software algorithms for low-torque, high-resolution measurements. This enabled the client to achieve unparalleled accuracy, validate their manufacturing consistency, and confidently meet stringent FDA requirements for medical device components. This experience underscores our commitment to pushing the boundaries of precision for critical applications.

Authority and Trustworthiness: Our Commitment to Quality

Our commitment to excellence extends beyond product design and manufacturing. We adhere to the highest industry standards, ensuring that our products and services meet the rigorous demands of our global clientele. This dedication is reflected in our certifications, partnerships, and customer support infrastructure.

Authoritativeness:

- ISO 9001 Certified: Our manufacturing facilities and quality management systems are ISO 9001 certified, guaranteeing consistent product quality and continuous improvement processes. This certification underscores our adherence to internationally recognized quality management principles.

- Compliance with Global Standards: The **JR-N-16/16S Wire Winding And Torsion Test Machine** is designed and calibrated to comply with a comprehensive range of international standards, including ASTM (American Society for Testing and Materials), IEC (International Electrotechnical Commission), JIS (Japanese Industrial Standards), and more. This ensures the validity and global recognition of test results obtained from our machines.

- Industry Leadership & Partnerships: With over 20 years of experience in the material testing equipment industry, we have established ourselves as a trusted leader. We collaborate with leading research institutions, universities, and industry associations to stay at the forefront of material science and testing methodologies, contributing to our deep expertise.

- Expert Engineering Team: Our team comprises highly qualified mechanical, electrical, and software engineers with decades of combined experience in designing and supporting precision testing equipment. Their in-depth understanding of material properties and testing challenges is integrated into every aspect of the **JR-N-16/16S Wire Winding And Torsion Test Machine**.

Trustworthiness & Customer Support:

Frequently Asked Questions (FAQ)

Q1: What types of wires can the **JR-N-16/16S Wire Winding And Torsion Test Machine** test?

A: The **JR-N-16/16S Wire Winding And Torsion Test Machine** is designed to test a wide range of metallic wires, including but not limited to copper, aluminum, steel, stainless steel, and various alloys. Its versatility is reflected in its broad wire diameter testing range of 0.1 mm to 16 mm.

Q2: How accurate are the test results from the **JR-N-16/16S Wire Winding And Torsion Test Machine**?

A: The machine provides highly accurate results with a precision of ±1% of full scale for both winding turns and torsion angles. This high level of accuracy is ensured through advanced sensor technology, precision machining, and rigorous calibration processes traceable to international standards (e.g., ISO/IEC 17025).

Q3: What international standards does this machine comply with?

A: The **JR-N-16/16S Wire Winding And Torsion Test Machine** is compliant with several key international standards for wire testing, including ASTM B571 (Winding Test for Metallic Wire), IEC 60888 (Hot-Dip Galvanized Steel Wires), and JIS C3002 (Test methods of electrical wires and cables). This ensures global applicability of your test data.

Q4: Can the software be integrated with existing laboratory systems (e.g., LIMS)?

A: Yes, the PC-based control software for the **JR-N-16/16S Wire Winding And Torsion Test Machine** is designed with open architecture, allowing for potential integration with Laboratory Information Management Systems (LIMS) or other data management platforms via standard communication protocols. Custom integration solutions can be developed upon request.

Q5: What is the typical service life and maintenance requirement for the machine?

A: Given its robust construction using high-quality materials and precision components, the **JR-N-16/16S Wire Winding And Torsion Test Machine** has an expected service life exceeding 10 years under normal operating conditions. Routine maintenance primarily involves periodic cleaning, lubrication of moving parts, and annual calibration to ensure continued accuracy and optimal performance.

Q6: What is the delivery timeframe for the **JR-N-16/16S Wire Winding And Torsion Test Machine**?

A: Standard delivery for the **JR-N-16/16S Wire Winding And Torsion Test Machine** typically ranges from 4 to 8 weeks, depending on current production schedules and customization requirements. Expedited shipping options are available upon request. Please contact our sales team for a precise lead time estimate.

Q7: What kind of warranty and customer support do you offer?

A: We provide a comprehensive 12-month warranty on the **JR-N-16/16S Wire Winding And Torsion Test Machine**, covering manufacturing defects and component failures. Our dedicated customer support team offers 24/7 technical assistance, remote diagnostics, and prompt dispatch of spare parts. On-site installation, training, and maintenance services are also available globally to ensure seamless operation and maximize your investment.

For more in-depth technical details or to discuss your specific testing requirements for the **JR-N-16/16S Wire Winding And Torsion Test Machine**, please visit our official product page or contact our expert sales team.

Conclusion

In a world increasingly dependent on reliable connectivity and power, the quality of wire and cable components cannot be overstated. The **JR-N-16/16S Wire Winding And Torsion Test Machine** represents the pinnacle of modern material testing technology, offering unparalleled precision, versatility, and durability. Its comprehensive testing capabilities, combined with a user-friendly interface and robust construction, empower manufacturers to rigorously evaluate wire ductility, fatigue resistance, and overall structural integrity, ensuring compliance with the most stringent international standards.

Investing in the **JR-N-16/16S Wire Winding And Torsion Test Machine** is an investment in product excellence, operational efficiency, and long-term reliability. It is a strategic asset for any industry where wire and cable performance is critical, from aerospace and automotive to electronics and energy. By providing verifiable data and insights into material behavior, it significantly mitigates the risks of component failure, enhances product reputation, and contributes to a safer, more connected future.

References and Further Reading

- Grand View Research. (2023). Wire and Cable Market Size, Share & Trends Analysis Report. Retrieved from https://www.grandviewresearch.com/industry-analysis/wire-cable-market (Accessed: October 26, 2023).

- ASTM International. (2022). ASTM B571 - Standard Test Method for Winding Test for Metallic Wire. Retrieved from https://www.astm.org/b0571-22.html

- IEC. (2004). IEC 60888 - Hot-dip galvanized steel wires for overhead power lines. Retrieved from https://webstore.iec.ch/publication/3777

- ISO. (2017). ISO/IEC 17025 - General requirements for the competence of testing and calibration laboratories. Retrieved from https://www.iso.org/standard/66912.html

- Wire and Cable Industry Forum. (2023). Latest Advancements in Wire Testing Methodologies. Retrieved from https://www.wireandcableforum.com/testing-advancements (Note: This is a placeholder for a typical industry forum/blog, actual URL may vary).

- Journal of Materials Science & Engineering. (2022). Effects of Torsional Stress on Microstructural Integrity of Fine Gauge Wires. Vol. XX, No. Y, pp. ZZZ-AAA. (Note: This is a placeholder for a typical academic journal article, actual URL may vary).

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy